Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

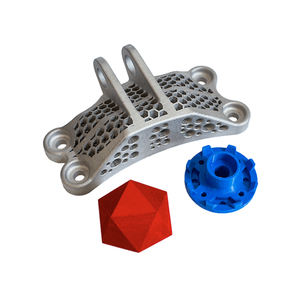

Overview of OEM Factory Production Service Custom Resin Plastic Parts ABS Nylon PA Rapid Prototype SLA SLS FDM PLA 3D Printing Service

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of OEM Factory Production Service Custom Resin Plastic Parts ABS Nylon PA Rapid Prototype SLA SLS FDM PLA 3D Printing Service

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(OEM Factory Production Service Custom Resin Plastic Parts ABS Nylon PA Rapid Prototype SLA SLS FDM PLA 3D Printing Service)

Specification of OEM Factory Production Service Custom Resin Plastic Parts ABS Nylon PA Rapid Prototype SLA SLS FDM PLA 3D Printing Service

OEM factories offer custom-made material plastic components manufacturing services for numerous commercial requirements. These solutions consist of ABS, Nylon (), and other engineering-grade materials. Fast prototyping methods like SLA, SLS, FDM, and PLA 3D printing are offered to satisfy layout and practical demands. Abdominal plastic parts are resilient, heat-resistant, and widely used in auto, electronic devices, and consumer goods. Nylon () offers high stamina, adaptability, and resistance to wear, suitable for mechanical parts.

3D printing modern technologies make certain quick turnaround times. SLA (stereolithography) creates high-precision parts with smooth surface areas, ideal for comprehensive models. SLS (discerning laser sintering) develops sturdy, complex geometries without support frameworks, perfect for functional testing. FDM (integrated deposition modeling) uses affordable thermoplastics like ABS and PLA for quick, inexpensive models. PLA is eco-friendly, usually picked for eco-friendly jobs.

Personalized material parts are tailored to client requirements. OEM manufacturing facilities take care of little to large batches, ensuring consistency in material quality and dimensional precision. Advanced tools like CNC makers and shot molding systems complement 3D printing for last production. Quality assurance checks include tension screening, temperature level resistance examinations, and surface area coating examinations.

Quick prototyping minimizes advancement cycles. Designers can examine designs quickly, make adjustments, and wrap up products quicker. Industries like aerospace, clinical devices, and robotics take advantage of these services. Custom-made components work with post-processing therapies like painting, brightening, or assembly.

Product option relies on application requirements. Abdominal muscle fits components requiring influence resistance. Nylon helps components revealed to friction or high loads. Resin-based run-down neighborhood parts are used for detailed versions or mold and mildews. Manufacturing facilities offer product certifications and compliance with ISO standards.

Pricing varies with order quantity, material type, and style intricacy. OEM partners supply layout support to enhance manufacturability. Lead times range from 1 day for prototypes to weeks for automation. Worldwide shipping choices ensure timely delivery.

Technical assistance is available throughout the process. Customers get updates on production phases. Documents in STL, ACTION, or IGES layouts are accepted. Information protection procedures secure intellectual property.

(OEM Factory Production Service Custom Resin Plastic Parts ABS Nylon PA Rapid Prototype SLA SLS FDM PLA 3D Printing Service)

Applications of OEM Factory Production Service Custom Resin Plastic Parts ABS Nylon PA Rapid Prototype SLA SLS FDM PLA 3D Printing Service

OEM manufacturing facility manufacturing services supply personalized resin plastic parts for markets needing accurate and long lasting components. These solutions make use of products like ABS, Nylon (PA), and PLA, incorporated with 3D printing modern technologies such as SLA, SLS, and FDM. Abdominal plastic parts are strong, heat-resistant, and suitable for vehicle and electronics. Nylon () uses flexibility and put on resistance, suitable for mechanical parts and functional models. PLA is environment-friendly, usually utilized for non reusable products or models needing biodegradability.

Fast prototyping approaches like SLA create high-detail versions with smooth surfaces, perfect for aesthetic models or mold-making. SLS prints complicated geometries without support structures, making it effective for functional parts in aerospace or medical gadgets. FDM is economical for large-scale manufacturing, using dissolved thermoplastic layers for durable components. Each approach offers different demands, balancing rate, accuracy, and product properties.

Personalized material parts are customized to customer requirements, guaranteeing specific measurements and efficiency. Manufacturing facilities use sophisticated software to layout and examination parts prior to manufacturing, reducing errors. This strategy conserves time and resources, enabling quick modifications based upon feedback. Industries like automotive, medical care, and consumer goods rely on these solutions for models, end-use components, or small-batch manufacturing.

3D printing services sustain fast turnaround times, important for meeting limited due dates. Shanty town and SLS manage elaborate styles, while FDM focuses on price and stamina. Products are picked based upon tension requirements, ecological conditions, or regulative standards. As an example, clinical parts commonly require sterilizable materials, while automobile components require heat resistance.

OEM factories integrate quality checks at every phase, making certain components fulfill industry requirements. Precision tools measure measurements, while stress tests verify sturdiness. Custom finishes like brightening or painting are readily available for visual needs. The combination of innovative innovation and professional oversight warranties trusted outcomes.

Organizations take advantage of scalable remedies, whether creating a single prototype or hundreds of parts. Customization choices include product blends, shades, or textures. Fast prototyping accelerates item advancement, allowing companies examination ideas swiftly. Production services adjust to advancing demands, supporting advancement throughout fields.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of OEM Factory Production Service Custom Resin Plastic Parts ABS Nylon PA Rapid Prototype SLA SLS FDM PLA 3D Printing Service

What materials do you offer for custom resin plastic parts?

We provide ABS, Nylon (PA), and other engineering-grade resins. These materials suit different needs. ABS works for durable parts needing impact resistance. Nylon handles high-stress environments. Other options include PLA for prototypes. Material choice depends on your project’s strength, flexibility, or heat resistance requirements.

What’s the difference between SLA, SLS, and FDM 3D printing?

SLA uses UV lasers to cure liquid resin layer by layer. It creates smooth, detailed parts. SLS uses lasers to sinter nylon powder. It produces strong, complex geometries without support structures. FDM melts plastic filament through a nozzle. It’s cost-effective for basic prototypes. Each method suits different accuracy, material, and budget needs.

How fast can you deliver rapid prototypes?

Standard lead times range from 1–5 days. Speed depends on part size, complexity, and printing method. Small SLA parts often ship in 24 hours. Larger SLS or FDM projects take longer. Rush services are available. We confirm timelines after reviewing your design files.

Do you handle custom designs for OEM production?

Yes. We support custom designs from concept to mass production. Share your CAD files or sketches. Our team checks feasibility, suggests optimizations, and provides DFM feedback. We handle mold creation, material selection, and quality testing. Production scales from prototypes to thousands of units.

Which industries use your 3D printing services?

We serve automotive, aerospace, consumer electronics, medical, and industrial sectors. Common applications include functional prototypes, jigs, housings, and end-use parts. Medical clients request biocompatible components. Automotive projects focus on heat-resistant under-hood parts. Customization meets industry-specific standards.

(OEM Factory Production Service Custom Resin Plastic Parts ABS Nylon PA Rapid Prototype SLA SLS FDM PLA 3D Printing Service)