Discover a professional 3D printing powder supplier

Can Your 3D Printer Spit Out a Metal Spring? Let’s Uncoil the Fact!

(can i 3d print a spring with metal filament)

3D printing keeps unexpected us. From plastic toys to prosthetic limbs, it feels like there’s absolutely nothing this technology can’t attempt. But when someone asks, “Can I print a metal spring?” eyebrows rise. Metal springs are all over– in pens, automobile engines, also your cushion. They’re straightforward however difficult. Coiled cable stores energy when crushed or extended. Now, think of making one layer by layer with a 3D printer. Sounds wild? Let’s dig in.

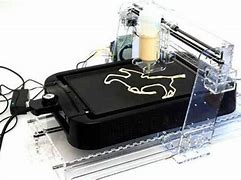

Initially, recognize this: steel 3D printing exists. Forget the inexpensive plastic spindles. Metal filaments are genuine. These blends usually mix powdered steels like steel or bronze with a plastic binder. After printing, you bake the item in a heating system. The binder burns away, leaving a strong metal part. It’s called “metal integrated filament manufacture” (MF3). Expensive term, however the concept is straightforward. Publish, then cook.

So, can you print a spring in this manner? Perhaps. The larger inquiry is: should you? Springs need flexibility and strength. They bend without breaking. Standard springtimes are made by winding warmed steel cord right into coils, after that tempering them. This procedure lines up the steel’s framework for sturdiness. 3D printing develops things in layers. Layer lines produce powerlessness. Despite steel, a published springtime may snap under stress.

Testing programs blended outcomes. Some enthusiasts print coil forms with metal-filled filament. After sintering (that high-temperature bake), the springtimes look metallic and feel tight. But do they jump? Not actually. Without appropriate tempering, they’re extra like stiff sculptures. Squeeze them, and they could not bounce back. Others attempt hybrid techniques. Publish a plastic springtime, after that electroplate it with metal. It adds a metallic covering however doesn’t address the core strength concern.

An additional difficulty is style. Springs rely on accurate geometry. The coil’s diameter, wire density, and variety of loops all issue. CAD software can model these, but printers fight with tiny information. Slim layers could fuse inadequately. Overhangs (like coiled loops) often require supports. Eliminating assistances from a delicate spring? Best of luck. Even if it endures post-processing, performance could let down.

Contrast this to classic springtimes. Manufacturers tweak alloys and treatments for particular tasks. Cars and truck springs handle heavy loads. View springs need precision. 3D-printed steel lacks this personalization. The filament’s residential or commercial properties are fixed. You get what remains in the spindle. Want to readjust versatility or solidity? Not quickly.

Still, interest drives advancement. Researchers trying out sophisticated techniques. Direct metal laser sintering (DMLS) utilizes lasers to thaw metal powder. It’s expensive yet can produce facility, resilient parts. Some companies publish titanium springtimes for aerospace. For a lot of us, though, industrial-grade machines are out of reach.

What concerning day-to-day usage? If you need a fast fix, a published steel springtime could work momentarily. State, a substitute for a broken clip in a low-stress gizmo. For critical applications– like a vehicle suspension– stick to standard springs. Safety and security initially.

The enjoyable part? Attempting anyhow. Get metal filament, tweak your printer settings, and struck “print.” Test various infill patterns. Maybe a honeycomb structure adds bounce. Cook it, after that see just how it stands up. Share your fails and wins online. That recognizes? Your tinkering could spark the following advancement.

(can i 3d print a spring with metal filament)

3D printing flourishes on “suppose?” questions. Steel springtimes are a hard nut to break, yet that’s the adventure. Every failed print shows something. Every half-working coil gets us closer. So fire up that printer. Experiment. Find out. And keep asking, “Can I do this?” even when the solution isn’t evident.