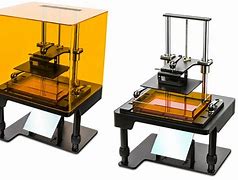

Discover a professional 3D printing powder supplier

** Plastic to Prestige: A Foolproof Overview to Making Your 3D Prints Mimic Steel **.

(how to make 3d prints look like metal)

Ever before looked at a 3D-printed things and desired it had the sleek, chilly glint of metal? You’re not alone. While plastic can not amazingly become steel, a few smart tricks can make your prints look like they simply presented of a foundry. Allow’s break down exactly how to provide your productions that metal shine without needing a blacksmith’s build.

Start with the fundamentals. Fining sand is your initial step. Fresh off the printer, most 3D prints have layer lines that yell “plastic.” Get sandpaper– start with crude grit (around 120) to smooth big flaws, after that switch over to finer grits (approximately 400) for a sleek surface. Wet sanding works better for products like PLA or material. Dip the sandpaper in water to minimize dust and stay clear of damaging. Take your time here. A smooth surface area is crucial for the following steps.

Guide follows. Think of it as makeup for your print. An excellent filler guide conceals small imperfections and develops an uniform base. Spray thin, also layers, allowing each layer completely dry entirely. Sand lightly between coats with fine-grit paper. 2 or 3 layers typically work. Currently your print is ready for its metallic makeover.

Paint is where the magic takes place. Routine spray paint will not cut it– go with metallic finishes. Brands like Rust-Oleum or Krylon use paints with actual steel particles. Shake the can hard, then spray in stable, sweeping motions. Hold the can around 12 inches away to stay clear of drips. Let the first layer dry, after that include a second for depth. For added realistic look, try “dry brushing.” Dip a tight brush in metallic acrylic paint, rub out most of it, then lightly drag it over sides and elevated details. This simulates used metal, like a classic robotic or weather-beaten equipment.

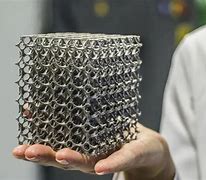

Wish to go pro? Attempt electroplating. This coats your print in actual steel making use of electricity. First, make your print conductive. Splash it with a graphite-based finishing or make use of a conductive primer. Immerse it in a plating solution (like copper or nickel) and hook it to a low-voltage source of power. Metal bits adhere to the surface area, producing a genuine metallic layer. It’s pricey and needs security gear, yet the outcomes are jaw-dropping.

Seal the deal with a clear layer. Metal paints can stain or damage. A glossy clear coat safeguards the coating and adds depth. For a weathered look, use a matte surface. Spray gently– too much can dull the metallic result. Allow it cure fully prior to taking care of.

Perk idea: Have fun with textures. Prior to painting, press rugged towel or aluminum foil right into the primer while it’s still gaudy. This develops a harsh surface area that captures light like hammered steel. Or make use of a warm gun to a little melt the surface for a molten-metal result.

Perseverance pays off. Rushing any type of action– sanding, priming, paint– will reveal. Metal coatings highlight problems, so prep job issues. Examination strategies on scrap prints first. Mix methods, as well. Dry brush over electroplating for a steampunk vibe, or layer different metallic paints for a built look.

(how to make 3d prints look like metal)

The best component? No one will certainly guess it’s plastic. Whether it’s a prop, fashion jewelry, or a screen piece, your “steel” print will trick also the sharpest eyes. So order those tools, welcome the mess, and start transforming humble plastic into something that radiates– actually.