Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

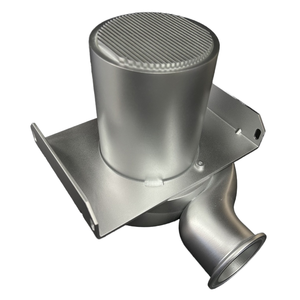

Overview of High Quality SLA Big Model 3D Printing Service Custom Large 3D Printed Rapid Prototype ABS Polyurethane Resin Print

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of High Quality SLA Big Model 3D Printing Service Custom Large 3D Printed Rapid Prototype ABS Polyurethane Resin Print

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(High Quality SLA Big Model 3D Printing Service Custom Large 3D Printed Rapid Prototype ABS Polyurethane Resin Print)

Specification of High Quality SLA Big Model 3D Printing Service Custom Large 3D Printed Rapid Prototype ABS Polyurethane Resin Print

Our High Quality SLA Big Design 3D Printing Service supplies precision-engineered services for custom massive models. The solution uses sophisticated Stereolithography (SHANTY TOWN) innovation to generate in-depth parts with smooth surface areas. Products include industrial-grade abdominal muscle and polyurethane material. These materials make certain resilience and high efficiency for functional testing and end-use applications.

The printing procedure sustains develop quantities as much as 1000mm x 600mm x 500mm. Layer resolution begins at 25 microns. This assures sharp information and tight tolerances. Facility geometries are possible without jeopardizing structural integrity. Components preserve dimensional accuracy within 0.1 mm. This makes them ideal for engineering recognition and assembly checks.

ABS supplies impact resistance and thermal stability. It works well for vehicle components and mechanical housings. Polyurethane material gives flexibility and great surface finishes. It is optimal for models calling for aesthetic appeal or rubber-like textures. Both materials are compatible with post-processing treatments. Alternatives consist of sanding, paint, and metal plating.

Fast turnaround times are prioritized. Conventional orders ship within 3-5 organization days. Expedited solutions are readily available for urgent projects. A devoted group examines style data in advance. This decreases mistakes and ensures optimal printability. Support frameworks are purposefully placed. They are very easy to get rid of without damaging fragile functions.

The solution caters to industries like aerospace, clinical devices, and consumer electronics. Applications include functional models, jigs, fixtures, and building versions. Customization includes material blends and mechanical residential properties. Components can be enhanced for toughness, flexibility, or heat resistance.

Quality checks are performed at every phase. This consists of pre-print calibration, in-process monitoring, and final assessment. Each part is gauged against customer requirements. Surface area problems or dimensional variances are fixed before shipment.

Scalability accommodates single prototypes to medium-batch manufacturing. Cost-efficiency improves with larger orders. No in advance tooling is called for. Style versions are simplified. Clients get real-time updates on job standing.

The service incorporates with CAD software. File layouts like STL, OBJ, and STEP are approved. Technical assistance is available for style optimization. Designers encourage on wall surface thickness, orientation, and material option.

This solution bridges the gap between quick prototyping and commercial production. It incorporates sophisticated modern technology with hands-on competence. Practical parts fulfill extensive efficiency standards. Aesthetic parts achieve showroom-ready finishes.

(High Quality SLA Big Model 3D Printing Service Custom Large 3D Printed Rapid Prototype ABS Polyurethane Resin Print)

Applications of High Quality SLA Big Model 3D Printing Service Custom Large 3D Printed Rapid Prototype ABS Polyurethane Resin Print

Premium SLA large design 3D printing solutions provide exact options for custom-made large prototypes and functional components. This modern technology uses advanced materials like abdominal and polyurethane resin. These materials make certain resilience and information. Industries rely on this solution for rapid prototyping and end-use production.

The auto industry benefits from SLA printing. Suppliers create complex components for screening. Personalized elements like control panel panels or engine installs are created promptly. ABS material deals with high stress and heat. This makes it ideal for automobile applications. Models are tested under actual problems right away.

Aerospace firms make use of large-format SLA printing for light-weight yet strong components. Generator blades or cabin components are printed with accuracy. Polyurethane resin mimics last products. Engineers validate styles prior to automation. This lowers expenses and speeds advancement cycles.

Clinical fields apply SLA printing for medical tools and anatomical models. Resins are biocompatible for sure applications. Surgeons method on patient-specific replicas. Personalized prosthetics are tailored to individual demands. Accuracy is critical below. SLA printing supplies the needed information.

Engineers and designers use this solution for range models. Complex structures are printed in high resolution. Polyurethane resin catches fine textures. Clients imagine tasks reasonably. Alterations are simple to apply. This streamlines the authorization procedure.

Customer item brand names count on SLA printing for prototypes. Electronics real estates or wearable tools are checked for comfort designs. Abdominal muscle material withstands wear and tear. Functional prototypes confirm functionality before launch. Modifications are made quickly.

Commercial devices makers produce jigs and fixtures with run-down neighborhood printing. Custom-made tools improve production line efficiency. Polyurethane material stands up to chemicals and abrasion. Substitute parts are published as needed. Downtime is reduced.

The adaptability of SLA printing supports varied needs. Products adjust to specific needs. Rate and accuracy satisfy tight target dates. Complex geometries are attainable without extra costs. Organizations conserve sources while preserving high quality.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of High Quality SLA Big Model 3D Printing Service Custom Large 3D Printed Rapid Prototype ABS Polyurethane Resin Print

What materials do you offer for SLA 3D printing?

We use high-quality ABS, polyurethane resin, and similar industrial-grade materials. These materials are strong, durable, and suited for detailed prototypes. They handle stress well and work for functional testing or final products. Material choice depends on your project’s needs.

What is the maximum size for printed parts?

Our large-format SLA printers handle parts up to 600 x 600 x 400 mm. Larger projects can be split into sections and assembled post-printing. We check design files first to ensure size compatibility.

How accurate are your 3D prints?

Prints achieve ±0.1 mm accuracy. This precision suits complex geometries and fine details. Layer thickness starts at 25 microns for smooth surfaces. Accuracy depends on part design and material. We optimize settings for each project.

How long does production take?

Standard lead times range from 1 to 5 days. Timing depends on part size, material, and complexity. Rush services are available for urgent projects. We provide updates at every stage.

What affects the cost of SLA printing?

Cost depends on material type, part volume, and print time. Complex designs requiring supports or post-processing (sanding, painting) add to costs. We offer free quotes based on your 3D files. Bulk orders reduce per-unit pricing.

(High Quality SLA Big Model 3D Printing Service Custom Large 3D Printed Rapid Prototype ABS Polyurethane Resin Print)