Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

Overview of Factory Direct Rapid Manufacturing For Industrial Applications Using Custom 3D Printing Dragon Toy Services

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

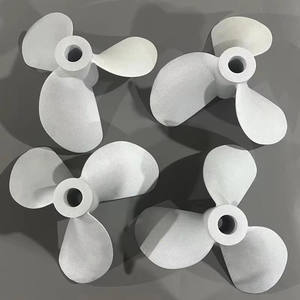

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of Factory Direct Rapid Manufacturing For Industrial Applications Using Custom 3D Printing Dragon Toy Services

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(Factory Direct Rapid Manufacturing For Industrial Applications Using Custom 3D Printing Dragon Toy Services)

Specification of Factory Direct Rapid Manufacturing For Industrial Applications Using Custom 3D Printing Dragon Toy Services

Manufacturing Facility Direct Rapid Manufacturing provides customized 3D printing solutions for commercial applications. The solution specializes in producing top quality dragon plaything models and practical components. It utilizes advanced 3D printing technology to satisfy specific design needs. The process begins with electronic designs. Clients send their layouts or demand support from the internal engineering group. Documents are checked for compatibility and enhanced for manufacturing. This ensures the final product matches the intended specifications.

Products available include plastics, materials, and steels. Each material is selected based upon strength, flexibility, and resilience requirements. Industrial-grade printers take care of complicated geometries. This permits complex details in dragon plaything designs. Components are published layer by layer. This method decreases waste compared to typical production.

The solution accommodates sectors like automobile, aerospace, and consumer goods. It supports small-batch manufacturing and large orders. Preparations are much shorter than traditional techniques. Tasks that take weeks with traditional tools can be completed in days. Prices remain low due to the fact that no molds or tooling are called for. Design changes can be made quickly. This flexibility accelerate item growth cycles.

Quality control is strict. Printed parts undergo inspections for dimensional accuracy and surface finish. Testing includes stress and anxiety resistance and useful checks. Clients receive regular results every single time. Technical assistance is available throughout the process. Experts aid with style changes or product choice.

The 3D printing process is environmentally friendly. It makes use of just the product needed for each and every part. Excess powder or resin is reused for future work. Power usage is less than machining or injection molding.

Customized options cover colors, structures, and surfaces. Dragon playthings can be painted or left raw. Assembly-ready components are published with pre-installed joints or adapters. Product packaging remedies safeguard things throughout shipping.

Manufacturing Facility Direct Quick Manufacturing makes certain quickly turn-around without compromising top quality. The solution is optimal for businesses needing reputable prototypes or end-use components. It adapts to one-of-a-kind job demands. Industrial clients conserve time and sources while achieving accurate outcomes.

(Factory Direct Rapid Manufacturing For Industrial Applications Using Custom 3D Printing Dragon Toy Services)

Applications of Factory Direct Rapid Manufacturing For Industrial Applications Using Custom 3D Printing Dragon Toy Services

Factory Straight Fast Production supplies custom 3D printing remedies for commercial requirements. These services are optimal for firms needing quickly, exact parts without high prices. The Dragon Plaything Services system utilizes sophisticated printing innovation to create industrial-grade elements. This method helps prototyping, production, and specialized tools.

Industries like automotive, aerospace, and electronics take advantage of this technique. Personalized parts are made quickly to fulfill tight due dates. Complex styles are easy to produce with 3D printing. This decreases reliance on typical manufacturing techniques. Manufacturing facilities save time and money by staying clear of pricey mold and mildews or long haul times.

The procedure begins with digital designs. Files are sent directly to commercial 3D printers. Materials like plastics, steels, and composites are made use of based upon task demands. Components are published layer by layer for accuracy. This makes certain premium outcomes every time.

Low-volume manufacturing runs are affordable with this method. Firms check new designs without big investments. Modifications can be made rapidly if adjustments are required. Customized tools or fixtures are published as needed. This keeps assembly line running efficiently.

Clinical devices manufacturers make use of these solutions for specialized tools. Custom installations or prototypes are made with medical-grade materials. Architectural companies print comprehensive versions for client discussions. University create accurate training help.

Resilience and precision are essential advantages. Printed parts withstand severe atmospheres and hefty use. Resistances are limited to meet market requirements. Surface area finishes are smooth or distinctive as needed.

The Dragon Toy Services team incorporates expertise in 3D printing and commercial needs. Orders are taken care of from layout to distribution. Assistance is offered for technical concerns or material choices. Quick turnaround times keep projects moving.

This service is scalable for small companies or big companies. No minimum order amounts apply. Rates is transparent without hidden charges. Quality checks ensure every part satisfies specifications.

Factory Direct Rapid Manufacturing bridges the void in between advancement and functionality. Customized services are customized to specific obstacles. Industries stay competitive with accessibility to innovative modern technology. Effectiveness boosts while prices stay controlled.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Factory Direct Rapid Manufacturing For Industrial Applications Using Custom 3D Printing Dragon Toy Services

What is Factory Direct Rapid Manufacturing for industrial applications using Custom 3D Printing Dragon Toy Services?

This service creates custom industrial parts fast using 3D printing. It focuses on producing strong, precise components for machinery, tools, or prototypes. The process starts with a digital design. The design is turned into a physical object layer by layer. This method skips traditional manufacturing steps.

What materials can be used for 3D printing industrial parts?

Common materials include plastics, metals, and resins. Plastics like ABS or nylon work for lightweight parts. Metals like aluminum or steel handle heavy-duty needs. Resins offer fine details for prototypes. Material choice depends on strength, heat resistance, or flexibility requirements.

How fast is the production process?

Production time varies by part size and complexity. Small parts take hours. Larger items take days. Design approval speeds things up. No tooling or molds are needed. This cuts waiting time. Rush orders are possible for urgent projects.

Are 3D-printed parts durable enough for industrial use?

Yes. Industrial-grade materials match traditional manufacturing standards. 3D printing layers bond tightly. Post-processing like polishing or coating adds strength. Testing ensures parts meet stress, temperature, or wear demands.

Is custom 3D printing cost-effective for small batches?

Yes. Traditional methods need expensive molds or setup fees. 3D printing costs depend only on material and machine time. Small batches avoid wasted resources. Custom designs don’t raise prices. This makes it ideal for testing or limited-run projects.

(Factory Direct Rapid Manufacturing For Industrial Applications Using Custom 3D Printing Dragon Toy Services)