Discover a professional 3D printing powder supplier

Can 3D Printed Metal Take a Punch? Evaluating the Limitations of Modern Manufacturing

(how strong is 3d printed metal)

Think of developing a cars and truck engine part or a rocket component not in a factory yet on a desk-sized device. This is the fact of 3D-printed steel. The large inquiry is straightforward: exactly how hard is this stuff? Can it deal with real-world demands, or is it just a modern uniqueness? Allow’s dig into the scientific research, the surprises, and the keys behind the strength of 3D-printed steel.

Initially, comprehend exactly how 3D-printed steel works. Unlike traditional methods where steel is carved or formed, 3D printing builds objects layer by layer. Think of it like piling sheets of paper, however each sheet is a hair-thin layer of steel powder merged by lasers or electron beam of lights. The result? A strong piece formed precisely as created. Yet does stacking layers this way make the steel weaker or stronger?

The solution isn’t straightforward. Conventional metals, like those cast in a shop, have an uniform structure. Their strength originates from being heated, put, and cooled in regulated methods. 3D-printed steels, though, have small “grain” patterns formed by exactly how the layers melt and strengthen. Sometimes these grains line up in manner ins which add stamina. Various other times, tiny gaps or incongruities pop up. It depends on the printer’s precision, the metal utilized, and just how the part is dealt with after printing.

Materials matter a great deal. Common 3D-printed steels consist of stainless-steel, titanium, and aluminum. Titanium, for example, is already recognized for being solid and light. When 3D-printed, it keeps these characteristics however gains new ones. Examinations show printed titanium components can match or even outperform built titanium in specific stress tests. But not every steel acts by doing this. Less expensive alloys might fracture under stress if the printing process isn’t tuned completely.

Post-processing is one more vital variable. Fresh published steel components typically undergo warm therapy, polishing, or perhaps machining to smooth harsh edges. These steps can get rid of weak points caused throughout printing. A research by a German engineering group located that heat-treated 3D-printed steel parts survived 30% longer under duplicated stress and anxiety than untreated ones.

Real-world examples verify the potential. Aerospace companies currently use 3D-printed steel components in jet engines. These components encounter extreme warm and stress daily. Medical implants, like spinal poles or hip substitutes, rely on printed titanium for its mix of stamina and compatibility with the body. Even the automotive market is evaluating published steel components for high-performance cars and trucks.

Still, obstacles exist. Layer-by-layer printing can develop internal tension factors. Think of gluing together plywood sheets– each layer holds, however the glue lines could be weak spots. In a similar way, improperly published steel could break along layer lines under hefty tons. Advanced printers now utilize strategies like “hot isostatic pressing” to squash layers with each other under high heat and stress, making the steel nearly as dense as standard versions.

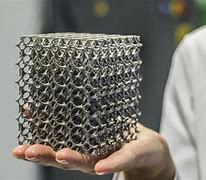

One more twist? Layout liberty. 3D printing allows designers produce forms impossible to make with traditional techniques. Honeycomb frameworks, hollow networks, or organic contours can be printed in metal. These forms frequently spread stress and anxiety a lot more evenly, making the part more powerful without adding weight. A drone propeller made this way could consider fifty percent as much as a solid steel one but take care of two times the force.

(how strong is 3d printed metal)

So, is 3D-printed metal strong enough? For many usages, yes. It’s not magic– poor printing or affordable materials will certainly still stop working. But with the best tech and ability, printed metal isn’t simply an alternative to conventional components. It’s a brand-new frontier, pushing what steel can do. Researchers maintain tweaking printers, testing alloys, and finding smarter layouts. Every breakthrough inches us closer to a future where “printed” doesn’t indicate “breakable”– it suggests “tough, light, and all set for anything.”