Discover a professional 3D printing powder supplier

** Metal Magic: Is 3D Printing Feasible? **.

(can we 3d print metal)

Imagine crafting detailed steel objects, layer by little layer, directly from an electronic design. It seems like natural science fiction. Think about intricate engine parts, custom-made clinical implants, or light-weight aerospace parts appearing out of nowhere. This isn’t dream anymore. We absolutely can 3D print metal. It’s happening right now in manufacturing facilities, labs, and workshops worldwide. The technology is genuine, powerful, and altering how we build points.

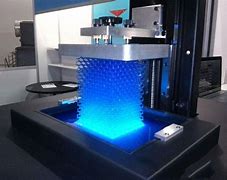

Forget the plastic trinkets from hobbyist printers. Steel 3D printing, often called additive production, is a whole different monster. It makes use of serious power and precision. The most typical technique entails lasers or electron light beams. Image a slim bed of super-fine metal powder, like extremely smooth metallic sand. An effective laser beam of light zaps details spots on this powder bed. It thaws the powder, integrating it right into solid steel. The device adds another thin layer of powder. The laser thaws the next pattern. This occurs over and over, building the things piece by piece from the bottom up. Think of it as micro-welding, one pinpoint area at a time.

Various other approaches exist too. Some spray out a paste packed with tiny steel particles, after that cook it solid. Others utilize routed energy to thaw metal cable as it’s fed in. The core idea remains the same: building metal components by including product, not cutting it away. This basic change unlocks amazing possibilities.

Why is this such a big deal? Conventional metalworking usually implies machining. You begin with a huge block of metal. You removed substantial chunks to obtain your final shape. It’s wasteful. Costly steel becomes scrap chips. Steel 3D printing includes just the material you require. Waste goes down substantially. That conserves cash and sources.

The genuine magic hinge on style liberty. Machining devices can not constantly reach complex inner spaces. Think about elaborate cooling networks inside a turbine blade or a lightweight lattice structure inside a bracket. Conventional methods battle or stop working with these. 3D printing pokes fun at these constraints. If you can design it digitally, you can most likely print it in steel. This allows engineers to produce forms that are stronger, lighter, and extra effective than ever before.

Take a look around. This isn’t simply laboratory talk. Aerospace giants print gas nozzles with impossible inner passages. They fly lighter, carry out far better. Medical professionals publish titanium implants custom-shaped to fit an individual’s unique bone framework. Perfect fit, faster recovery. Auto makers prototype complex components overnight. Jewelers create elaborate styles as soon as deemed unmakeable. Even toolmakers create durable, custom-made jigs and fixtures promptly.

Certainly, it’s not all sunlight and lasers. Metal 3D printing has obstacles. The machines themselves set you back a fortune. We’re speaking industrial-grade equipment, not desktop toys. The process is slow-moving. Publishing a single facility part can take numerous hours, also days. The steel powders need careful handling. They are expensive and potentially harmful. The final components often need substantial completing work. Surface area smoothing, warmth treatment, or precision machining might still be needed. Speed and price continue to be obstacles for automation today.

(can we 3d print metal)

The modern technology is evolving exceptionally quick. Scientists frequently push borders. They establish brand-new metal powders, faster printing techniques, smarter software. Prices are slowly coming down. Capacities keep expanding. What was impossible 5 years ago is regular today. What appears advanced currently will likely end up being prevalent soon. The prospective really feels almost infinite. Steel 3D printing allows us reconsider the very nature of manufacturing. It moves us beyond the limits of molds and reducing tools. It opens up doors to totally brand-new ways of engineering the globe around us, building complex metal wonders directly from the digital world.