Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

Overview of 3d printing service sls cheap rapid prototyping sls 3d printer prototyping moulding service

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of 3d printing service sls cheap rapid prototyping sls 3d printer prototyping moulding service

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(3d printing service sls cheap rapid prototyping sls 3d printer prototyping moulding service)

Specification of 3d printing service sls cheap rapid prototyping sls 3d printer prototyping moulding service

Our SLS 3D printing service supplies low-cost rapid prototyping making use of industrial-grade discerning laser sintering innovation. We fuse nylon powder with high-power lasers to construct long lasting components layer by layer. This technique creates solid practical models quick without needing assistance frameworks. You conserve money and time since complicated styles print quickly.

We manage jobs from solitary pieces to tool batches. Our machines generate get rid of good precision. Normal resistances hit around ± 0.3 mm. Surface surfaces remain sensibly smooth right off the printer. We provide basic nylon PA12 material. It works well for screening mechanical homes. The product endures influences and stands up to light chemicals.

Turnaround times fast. Common orders ship within 3 business days. Thrill choices exist for urgent jobs. Post your CAD data online. Our group checks geometry and recommends optimizations for cost or toughness. We sustain STL and OBJ layouts. Optimum build size is 300mm x 300mm x 300mm. Wall thickness should go beyond 1mm for security.

This service fits model testing, useful components, and custom devices. Many clients use it for snap-fit settings up or real estates. Others produce master patterns for silicone moulding. SLS components withstand warm far better than FDM prints. They will not melt listed below 170 ° C. Anticipate some rough texture and slight bending on big level surfaces. Post-processing like sanding or dyeing is offered individually.

Rates remains reduced with efficient equipment scheduling and mass product sourcing. Small components start at a few dollars each. Volume price cuts request orders over fifty systems. Free style testimonial avoids failed prints. Our designers flag potential concerns early. Obtain instant quotes on the internet anytime.

(3d printing service sls cheap rapid prototyping sls 3d printer prototyping moulding service)

Applications of 3d printing service sls cheap rapid prototyping sls 3d printer prototyping moulding service

SLS 3D printing solutions provide low-cost fast prototyping for many sectors. This innovation makes use of lasers to fuse nylon powder into strong components. It produces sturdy prototypes quickly. Several companies use it for product development. Engineers test designs swiftly by doing this. Designers confirm forms and fits early. This conserves time and money prior to mass production.

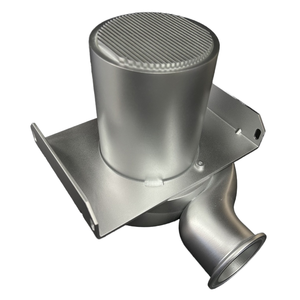

The auto field relies on SLS for practical models. Automobile components like ducts and real estates obtain printed quickly. These parts withstand warmth and stress tests. Aerospace groups make use of SLS as well. They make light-weight cabin elements and drone components. Medical fields print custom surgical overviews and tool models. These match patient makeup exactly.

Durable goods makers benefit substantially. They model ergonomic tool deals with and electronic casings. SLS allows complex geometries conveniently. Standard techniques battle with complex forms. Fashion jewelry designers publish comprehensive wax patterns for casting. Engineers construct exact range versions of structures.

SLS offers mould making needs likewise. It prints long lasting master patterns for silicone moulds. These moulds produce little sets of urethane parts. This avoids expensive steel tooling for brief runs. Makers inspect item feature with these urethane copies. They examine shades and textures prior to devoting to manufacturing.

Expense performance specifies SLS prototyping. It removes tooling expenses for one-off items. Material waste remains low because extra powder gets recycled. Preparations diminish dramatically. Components print over night instead of waiting weeks. Services repeat layouts quicker. They identify defects early and improve items quicker. This accelerates market launches.

Small companies gain access to expert prototyping now. SLS makers handle high-detail work economically. Startups confirm ideas without large budget plans. Even enthusiasts commission complicated custom items. The modern technology equalizes manufacturing abilities. Any person can turn electronic files right into physical items rapidly.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of 3d printing service sls cheap rapid prototyping sls 3d printer prototyping moulding service

What exactly is SLS 3d printing?

SLS stands for Selective Laser Sintering. A powerful laser melts tiny plastic powder particles together. It builds your part layer by layer. No support structures are needed. This makes complex shapes possible.

Why is SLS considered a cheap prototyping method?

SLS uses powdered nylon plastic. This material costs less than resins or metals used in other methods. The process is highly automated. Less manual labor keeps prices down. Machines build parts packed together. This maximizes material use per job. You get good value.

How fast is SLS rapid prototyping?

SLS is fast for functional prototypes. Typical turnaround is 2-5 working days. This includes printing and basic finishing. Complex parts take similar time to simple ones. The laser sinters the whole powder bed layer at once. Your part is ready quickly.

What materials can you use with SLS?

We mainly use Nylon 12 (PA12). It’s strong, durable, and slightly flexible. It handles heat and chemicals well. PA12 is perfect for testing functional prototypes. We also offer glass-filled nylon for extra stiffness. Some colors are available. Ask about options.

What size parts can your SLS printers make?

Our machines handle parts up to 300 x 300 x 300 mm. This fits most prototype needs. We can print multiple smaller parts together in one build. This saves time and cost. Need something bigger? Contact us. We might find a solution.

(3d printing service sls cheap rapid prototyping sls 3d printer prototyping moulding service)