Discover a professional 3D printing powder supplier

**Title: Printed Power vs. Molten Muscle: Can 3D Metals Match Casting Strength?**

(do 3d printed metals have the strength of castings)

So, you want strong metal parts. Maybe it’s for a car engine, maybe it’s for a tough machine tool. For ages, casting metal – pouring molten metal into a mold – was the king of making strong, solid pieces. Now, 3D printing metals is here, buzzing with promise. It builds parts layer by layer, straight from a computer file. Cool, right? But the big question hits hard: can these printed metals ever be as strong as the old-school cast stuff? Let’s dig into this metal match-up.

It’s tempting to want a simple yes or no answer. The truth is much more interesting. It depends. Really depends. Cast metal has history on its side. The process often results in a consistent internal grain structure throughout the part. Think of grains like tiny crystals inside the metal. Consistent grains often mean predictable, good strength in all directions. Castings are generally considered very strong, especially under steady loads like constant pressure or weight.

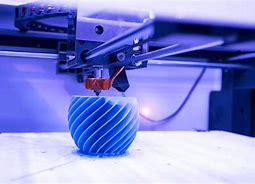

Enter the challenger: metal 3D printing. Think laser beams or electron beams melting fine metal powder, building your part slice by tiny slice. This layer-by-layer approach is its superpower and also its potential weakness. Why? The heat from the laser hits the metal intensely but very locally. This creates unique cooling patterns. These patterns can lead to a grain structure that’s different from casting. The grains might be finer, which can be good for strength sometimes. But the grains might also line up in certain directions based on the printing path. This means the printed part might be super strong in one direction but potentially weaker in another. We call this “direction matters” – anisotropic properties. Castings usually don’t have this issue; they are more “same strength everywhere” – isotropic.

Here’s another key player: tiny holes. Both processes can create them. In castings, air bubbles might get trapped as the metal cools in the mold. In 3D printing, tiny gaps can form between melted layers or where powder wasn’t perfectly melted. These little holes are weak spots. They act like stress concentrators. Think about tearing paper – a tiny nick makes it tear much easier. Modern printing is getting much better at minimizing these holes. Good printing settings and powerful machines make a big difference. Casting techniques have also improved massively over centuries to reduce porosity. So, both sides fight this battle.

Heat treatments change the game for both. Cast parts almost always get heat treated. This involves heating them up in controlled ways then cooling them down. It refines the grain structure, removes stresses, and boosts strength significantly. Guess what? 3D printed metals need heat treatments too. Often, they need it even more. The intense, localized heating and rapid cooling during printing can leave behind internal stresses. These stresses can make the part warp or even crack. Heat treatment after printing fixes this. It also helps fuse the layers together better and improves the grain structure. After proper heat treatment, a well-printed part can absolutely reach strength levels equal to, or sometimes even exceeding, a heat-treated casting of the same alloy. The starting material matters hugely too. Printing common aerospace alloys like titanium or Inconel often yields fantastic results.

So, which side wins? It’s not a clear knockout. Castings offer proven, consistent strength, especially in bulkier shapes. They remain the champion for massive, simple parts produced in huge numbers. 3D printing brings incredible design freedom. It makes shapes castings can only dream of – internal channels, super-lightweight lattices, complex curves. For these intricate designs, the printed part might be the *only* practical way to make it strong enough. The real question isn’t “which is stronger always?” It’s “which process gives the strength I need *for this specific part, with its specific design, made from this specific alloy, and used in this specific way*?”

(do 3d printed metals have the strength of castings)

The choice boils down to the job. Need a simple, chunky gear for a tractor? Casting might still be your best bet. Need a super-light, complex fuel nozzle for a rocket engine, packed with internal cooling channels? A well-printed, properly heat-treated metal part will likely be the stronger, more efficient solution. The printed metal’s strength is now firmly in the ring. It often punches right alongside its cast counterpart. Sometimes, it lands the winning blow.