Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

Overview of DM1014-10 big 3D Printer high accuracy fast industrial 3d printing machine imprimante 3d impresora printer

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

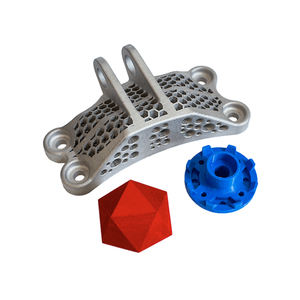

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of DM1014-10 big 3D Printer high accuracy fast industrial 3d printing machine imprimante 3d impresora printer

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(DM1014-10 big 3D Printer high accuracy fast industrial 3d printing machine imprimante 3d impresora printer)

Specification of DM1014-10 big 3D Printer high accuracy fast industrial 3d printing machine imprimante 3d impresora printer

The DM1014-10 is a big industrial 3D printer built for demanding work. It handles large parts easily. Its build volume is substantial. You can print objects measuring 1000mm x 1000mm x 1400mm. This large size is its main advantage.

Accuracy matters with this machine. It achieves high precision consistently. Layer resolution goes down to very fine details. The printer uses a sturdy frame. This frame minimizes vibrations during printing. Vibrations cause problems. The machine avoids them. You get smooth surfaces and sharp features every time.

Speed is another key point. The DM1014-10 prints fast. It uses powerful motion systems. It heats materials quickly. Large parts finish much faster than with smaller printers. Overnight prints become possible for big objects. This saves valuable production time.

It works with many strong engineering plastics. ABS, PETG, Nylon, and Polycarbonate are common choices. These materials are tough. They handle stress well. The printer heats the build chamber. This prevents warping. Warping ruins prints. The heated chamber stops it.

Reliability is crucial for factories. The DM1014-10 runs non-stop for long periods. Its components are industrial-grade. Maintenance needs are predictable. Downtime is minimized. Production schedules stay on track.

This printer fits industries needing big, precise parts fast. Automotive prototypes, aerospace tooling, and large functional components are typical uses. It offers a serious solution for large-scale additive manufacturing.

(DM1014-10 big 3D Printer high accuracy fast industrial 3d printing machine imprimante 3d impresora printer)

Applications of DM1014-10 big 3D Printer high accuracy fast industrial 3d printing machine imprimante 3d impresora printer

The DM1014-10 industrial 3D printer takes on demanding manufacturing obstacles. Its enormous construct volume handles large prototypes and manufacturing components quickly. Aerospace engineers utilize it for full-scale wind turbine real estates and wing components. Medical laboratories publish detailed physiological versions for medical preparation.

This device supplies extreme precision. Layer resolution to 50 microns records intricate information. Tooling suppliers rely upon it for injection molds with ideal tolerances. Precious jewelry designers create intricate wax patterns for casting.

Speed sets this printer apart. It prints four times faster than basic commercial versions. Automotive factories produce custom jigs overnight. Construction companies make architectural versions in hours not days.

Toughness meets commercial demands. The enclosed chamber handles engineering-grade materials like abdominal muscle and nylon. Chemical-resistant parts survive severe factory settings. Marine devices prototypes stand up to deep sea screening.

Manufacturing versatility increases effectiveness. Factories reduce assembly actions with integrated multi-part prints. Electronic devices business installed circuitry networks during printing. Custom product packaging mold and mildews adjust promptly for short runs.

Product convenience broadens applications. The heated bed handles carbon fiber composites for light-weight drones. Temperature level control guarantees constant results with adaptable filaments. Industrial users switch products between work without recalibration.

This printer cuts operational expenses. Decreased waste decreases material investing. Marginal post-processing conserves labor time. Producers change metal elements with high-strength published alternatives.

Real-world adoption shows its value. Robotics teams print sturdy gear assemblies on demand. Film studios develop in-depth props under tight deadlines. R&D divisions iterate intricate styles rapidly.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of DM1014-10 big 3D Printer high accuracy fast industrial 3d printing machine imprimante 3d impresora printer

FAQ 1: What size can the DM1014-10 print?

This industrial 3D printer handles big projects. Its build volume is 1000mm x 1000mm x 400mm. You make large parts in one piece. No gluing smaller sections together.

FAQ 2: How fast is this printer?

It prints very fast. Speeds hit 500mm per second. Complex industrial parts finish quicker. Production schedules stay tight.

FAQ 3: What materials work with it?

Use many materials. PLA, ABS, PETG are standard options. Nylon and carbon fiber composites work too. The extruder heats to 300°C. That handles tough filaments easily.

FAQ 4: Is the accuracy good?

Precision is excellent. Layer resolution goes down to 0.05mm. Parts come out sharp. Details stay crisp. Tolerances stay tight every time.

FAQ 5: Can it run all day in a factory?

Yes. The metal frame is heavy duty. It works nonstop 24/7. Safety features prevent overheating. Emergency stops protect operators. This machine fits tough workshops.

(DM1014-10 big 3D Printer high accuracy fast industrial 3d printing machine imprimante 3d impresora printer)