Discover a professional 3D printing powder supplier

** Title: Metal Magic: What’s the Big Bargain With 3D Printed Metal? **.

(why would a have 3d metal printing?)

Visualize developing a rocket engine part. Consider making a personalized hip joint for an individual. Image crafting a complicated device for a race auto. These points sound challenging. They utilized to be almost difficult or insane expensive. Then 3D metal printing appeared. It altered everything. Why does this matter? Why would certainly any individual bother printing steel?

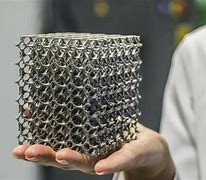

Initially, neglect simple plastic toys. Metal printing constructs real, strong, usable points. It constructs them layer by little layer. This method lets designers produce forms old manufacturing facilities simply can’t handle. Consider turning networks inside a jet engine part. Image fragile latticework structures making a bone dental implant lighter. These styles improve efficiency. They save weight. They make points work better. Old cutting and molding techniques struck limits. 3D printing shatters through those wall surfaces.

Next, modification comes to be easy. Automation needs hundreds of identical items. It’s cheap per item. Yet what regarding one unique component? Possibly an uncommon vintage car requires a replacement bracket. Maybe a specialist needs a perfectly shaped bone plate. Standard techniques set you back a ton of money for one thing. 3D printing doesn’t care. Style the documents. Publish the single piece. Done. It’s fast. It’s reliable. It fixes special issues without damaging the financial institution.

Rate matters as well. Designing a repair commonly takes ages. Initially, designers draw it. After that they make molds or equipment devices. Lastly, they test models. It consumes months. Occasionally years. 3D printing slashes that time. Design the component electronically. Send it straight to the printer. Hold a physical prototype in hours or days. Test it. Change the electronic documents quickly. Publish it once more. This quick turnaround speeds up innovation. Firms repair problems quicker. They bring better items to market faster.

Take a look at real jobs now. Aerospace business print fuel nozzles. These nozzles combine lots of parts right into one. They execute far better. They last much longer. Hospitals publish titanium implants. These implants match an individual’s bone exactly. Recovery enhances. Automotive groups publish personalized jigs and devices. These devices aid build autos quicker on the production line. Artists print complex metal sculptures. Styles when difficult ended up being truth.

Material waste drops substantially. Old techniques like machining beginning with a big steel block. They removed most of it. You end up with a tiny part and a big pile of scraps. 3D printing includes product only where required. It utilizes simply sufficient metal. This saves money. It’s much kinder to our earth. Less mining. Much less power utilized. Less things thrown out.

Consider spare parts for old machines. Factories typically stop making parts for older devices. Discovering replacements comes to be a headache. Storehouses supply heaps of parts simply in situation. It ties up cash and space. Currently, scan the busted component. Print a new one as needed. No enormous inventory required. No desperate searches. Devices remain running longer.

(why would a have 3d metal printing?)

The expense of printers falls steadily. Products become more readily available. The innovation keeps improving. More industries uncover its power. It’s not magic. But it really feels close. It solves tough issues. It makes the impossible feasible. It constructs things we merely could not build previously. That’s the genuine magic of steel printing.