Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

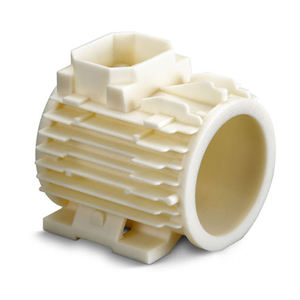

Overview of Manufacturing ABS plastic OEM products VR Headset SLS SLA Rapid Prototype Resin 3D printing service

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of Manufacturing ABS plastic OEM products VR Headset SLS SLA Rapid Prototype Resin 3D printing service

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(Manufacturing ABS plastic OEM products VR Headset SLS SLA Rapid Prototype Resin 3D printing service)

Specification of Manufacturing ABS plastic OEM products VR Headset SLS SLA Rapid Prototype Resin 3D printing service

Right here’s the product content:

We make solid abdominal muscle plastic parts for your VR headset tasks. Abdominal muscle plastic functions wonderful. It manages rough use well. Abdominal muscle plastic resists bumps and drops. Your VR headset prototypes require this sturdiness. Individuals use VR headsets a lot. They require to last. ABS plastic is likewise light. Hefty headsets really feel uneasy. ABS plastic keeps the weight down. Comfort matters for lengthy virtual reality sessions.

We develop your ABS plastic parts quick. Rate is important for getting your product to market. We make use of advanced approaches. SLS printing is one option. SLS integrates great plastic powder with a laser. It makes complex forms conveniently. No support structures are required. This conserves time. SLA printing is an additional option. SLA makes use of liquid resin cured by light. It develops extremely smooth surfaces. SLA records small information flawlessly. You see every function clearly. Both SLS and run-down neighborhood supply excellent models promptly.

Send us your VR headset style data. We examine them thoroughly. We pick the most effective abdominal plastic material for your needs. After that we print your parts using SLS or shanty town modern technology. We ensure premium quality every single time. After printing, we cleanse the components well. We get rid of any kind of extra material. We evaluate each prototype very closely. We ensure it matches your layout exactly. You get components prepared for testing quickly. Examining your layout early discovers issues sooner. Taking care of concerns early conserves cash later on.

Our solution assists you develop better virtual reality headsets faster. Obtain useful models in your hands promptly. Assess the look properly. Evaluate the comfort designs and fit correctly. Refine your layout based on actual components. Quicken your entire development cycle. Our rates is affordable. We provide great value for specialist outcomes. Contact us with your project information. We supply a quote immediately. Allow’s construct your VR headset model together. Beginning your project today.

(Manufacturing ABS plastic OEM products VR Headset SLS SLA Rapid Prototype Resin 3D printing service)

Applications of Manufacturing ABS plastic OEM products VR Headset SLS SLA Rapid Prototype Resin 3D printing service

Manufacturing ABS plastic OEM items provides sturdy services for virtual reality headset production. Abdominal muscle plastic uses strength. It takes care of everyday bumps well. It gives great influence protection for headsets. We mold abdominal muscle parts specifically. This makes sure consistent high quality for headset frames and parts. Modification alternatives exist. We tailor forms, appearances, and colors to match your brand name vision exactly.

Quick prototyping is important for virtual reality development. We offer SLS and run-down neighborhood 3D printing solutions. SLS builds strong, useful prototypes layer by layer making use of nylon powder. It’s excellent for testing headset mechanisms and fit. SLA utilizes liquid material cured by light. It develops exceptionally smooth, detailed parts. You see your design clearly. Both approaches turn concepts into real components fast. You check comfort designs early. You discover design problems prior to mass production.

Material 3D printing stands out for fine details. It produces high-resolution prototypes. Surface area surface matters for visual prototypes or small elaborate features. We print resin components accurately. You review aesthetics efficiently. This service enhances abdominal muscle production and SLS/SLA prototyping.

Our services cover the whole VR headset development trip. Start with quick models utilizing SLS or run-down neighborhood to confirm your idea. Refine details with resin printing. After that relocate to trusted abdominal plastic molding for the end product. This incorporated strategy conserves time and lowers risk. Get useful prototypes in days. Accomplish market-ready ABS elements effectively.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Manufacturing ABS plastic OEM products VR Headset SLS SLA Rapid Prototype Resin 3D printing service

FAQ: ABS Plastic VR Headsets & Prototyping Services

Why choose ABS plastic for VR headset parts?

ABS plastic is tough. It handles drops and bumps well. ABS plastic resists scratches. This matters for daily headset use. ABS plastic isn’t too expensive. It gives good value.

What makes ABS good for OEM headset production?

ABS plastic is easy to mold precisely. This is key for complex headset shapes. ABS plastic accepts many finishes well. Think painting or texture. ABS plastic balances strength and weight. Headsets stay comfortable.

What’s the difference between SLS and SLA for prototypes?

SLS uses nylon powder. It makes strong, functional parts. Think hinge tests. SLA uses liquid resin. It makes super detailed, smooth parts. Think visual models. Both are fast.

Why use resin printing for headset prototypes?

Resin printing (like SLA) gives amazing detail. You see fine textures clearly. Resin parts have a smooth surface finish. They look almost like final products. Resin printing is very fast for complex shapes.

How long does prototyping and production take?

Prototyping is quick. SLS or SLA parts often ship in days. Small ABS production batches might take weeks. Larger ABS orders take more time. We give clear timelines upfront. Speed depends on complexity and order size. We focus on getting it right.

(Manufacturing ABS plastic OEM products VR Headset SLS SLA Rapid Prototype Resin 3D printing service)