Discover a professional 3D printing powder supplier

** From Plastic to Steel: Can You Cast Your 3D Print? **.

(can i metal cast a 3d printed figure)

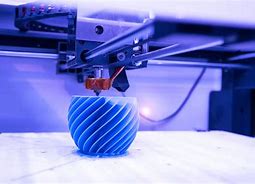

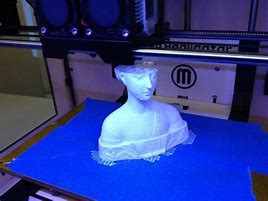

So you’ve got this amazing 3D published figure. Possibly it’s a hero, a monster, or a personalized piece you developed on your own. Plastic is cool, sure. However what happens if you want something much heavier? Something with that said significant, cold weight of steel? The huge inquiry pops up: can you in fact transform that plastic print into solid metal? The easy answer is indeed, definitely. It takes work, some expertise, and safety and security gear, but it’s an amazing method to level up your productions.

Think about it like making a mold and mildew from your print and after that filling that mold with steel. That’s the core concept. Your 3D published number comes to be the beginning point, the master pattern. You do not cast the plastic itself directly. Instead, you use it to produce an unfavorable area– a mold and mildew dental caries– that perfectly matches its form. Molten metal gets poured into this cavity. As soon as the metal cools down and hardens, you break away the mold material. What’s left? Your initial design, reborn in steel.

The procedure commonly makes use of a method called “lost wax casting.” Your 3D print acts like the wax model. Below’s the bargain. You frame your plastic number completely in a special mold and mildew material. This material needs to be incredibly tough. It has to make it through the insane heat of liquified steel. Common options are plaster combined with sand or special financial investment plaster. Your print gets buried inside a flask, surrounded by this slurry. After that all of it sets hard.

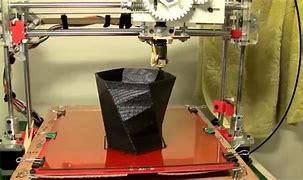

Currently comes the intense component. The whole mold, with your plastic print entraped inside, goes into a very hot kiln or stove. The warm does 2 critical work. Initially, it bakes the mold material, making it shake hard. Second, and most importantly, it entirely burns out the plastic print. The plastic disappears. It vaporizes. It vanishes totally. But the cavity it occupied remains perfectly inside the hard mold and mildew. This leaves a hollow space shaped specifically like your original number.

Successive is the steel. You need steel with a melting factor less than the temperature your mold and mildew can handle. Light weight aluminum is a prominent option. It thaws around 660 ° C( 1220 ° F ), which is convenient with the best setup. Brass and bronze are additionally options, needing hotter temperatures. Safety and security is non-negotiable right here. Molten metal is blazing warm and extremely unsafe. You need proper protective gear: a full face shield, hefty handwear covers, a natural leather apron, and clothing covering all skin. Never avoid this. Operate in an extremely well-ventilated area, preferably outdoors. Have safety and security tools like sand or a proper Course D fire extinguisher nearby.

You thaw your picked metal in a crucible utilizing a heating system. Once it’s completely fluid, you meticulously pour the glowing steel right into the cavity in your pre-heated mold. You pour steadily to prevent bubbles or spaces. After that you wait. The steel requires time to cool down and come to be solid once again inside the mold and mildew. This takes perseverance. Rushing it can ruin the piece. After cooling, you damage the mold and mildew material away from the metal spreading. This is often unpleasant. You could need hammers, blades, or water. Ultimately, you tidy up the raw steel casting. This involves removing any type of extra metal from the putting channels (called sprues and gateways), grinding down rough sides, fining sand, and polishing. This action transforms the rough casting into your last metal number.

Not all plastics function the very same. Requirement PLA filament is actually a great candidate for this “lost PLA” method. It burns out cleanly in the kiln. ABS can function too, however often leaves more ash deposit. Material prints need additional caution. Some materials could not wear out cleanly or can release unpleasant fumes. Research your particular resin if you perform. The detail on your initial print issues hugely. Fine information like slim blades, small structures, or sharp points may not make it through the fatigue procedure or fill flawlessly with steel. Less complex, chunkier styles typically cast better, especially when you’re beginning.

(can i metal cast a 3d printed figure)

Steel casting your 3D prints unlocks amazing possibilities. It connects digital layout and tangible, sturdy steel items. It calls for substantial initiative, correct tools, and rigorous safety and security methods. The contentment of holding that heavy, metal variation of your digital production is tough to defeat. Start little, find out the steps very carefully, focus on security over everything else, and appreciate the unbelievable transformation from plastic pixels to strong metal.