Discover a professional 3D printing powder supplier

Formlabs and Steel 3D Printing: Close Friends or Adversaries?

(does formlabs use metal 3d printing)

The world of 3D printing hums with opportunities. Steel printing grabs headings. It promises incredibly strong parts for rockets and clinical implants. People see the hype. They ask, “Does Formlabs utilize steel 3D printing?” The easy answer is no. Formlabs makers do not publish metal straight. They function in a different way.

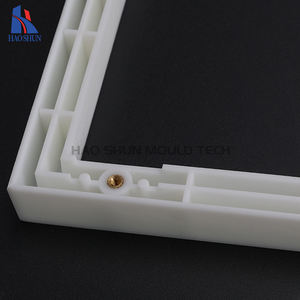

Formlabs developed its name on material. Their printers use light. Exact lasers or projectors heal fluid resin layer by layer. The result? Surprisingly thorough plastic components. Assume smooth surfaces. Believe great functions impossible for various other printers. Think oral designs or elaborate precious jewelry prototypes. These equipments fit on a desk. They hum quietly. They come. Metal printing is another beast completely. It commonly entails high-power lasers thawing metal powder. This requires special chambers. It requires effective lasers. It requires severe safety equipment. Think large industrial machines. Think manufacturing facility floorings. The price is high. The complexity is high. Formlabs focuses on making 3D printing easier. They concentrate on price. Metal printing is not their game.

Check out their line of product. You see the Kind 3, Kind 3L, the new Form 4, Type 4K. These are all resin powerhouses. They use Formlabs’ own unique resins. These materials come in numerous types. Some mimic hard design plastics. Some are flexible like rubber. Some are even ceramic-filled. But steel? Not in the container. You will not fill steel powder into a Formlabs printer. It simply does not function that way.

This doesn’t indicate Formlabs neglects steel. They recognize its significance. They see the demand. Their strategy is clever. They companion. Formlabs functions closely with business specializing in steel printing. Just how? A designer could produce a component on a Formlabs material printer initially. They obtain the design ideal. They check the fit. They inspect the function. It’s fast. It’s economical compared to steel. When the design is locked in, they send the documents out. A solution bureau utilizes a devoted steel printer to make the last component. Formlabs resin printers are perfect for this prototyping step. They conserve time. They save money before dedicating to costly metal.

Additionally, Formlabs provides amazing material materials. Some imitate metal’s feel and look incredibly well. Take ‘Hard Metal Resin’ or ‘Copper Load’. These materials publish conveniently on any type of Formlabs machine. After printing, you brighten them. They shine like real bronze or copper. It’s not real metal. It will not perform electrical energy like steel. But also for ornamental products, outfit precious jewelry, or visual prototypes needing a metal coating? They are fantastic. They consider that metal result without the steel price or headache.

(does formlabs use metal 3d printing)

So, Formlabs printers are material masters. They stand out at detail and access. Steel printing requires various tools, various competence. Formlabs recognizes this. They focus on what they do best. They make effective material printing devices for specialists. They additionally make it very easy to bridge the gap to steel when required via wise operations and partnerships. They encourage designers to reach that final metal part quicker and smarter. Their world is fluid material transformed by light, not liquified steel powder. It’s a different path to innovation.