Discover a professional 3D printing powder supplier

Okay, right here’s that post, revised for a human touch, concentrating on clear flow and preventing AI finger prints:

(how to 3d print metal parts)

** Metal Magic: Your Level Talk Overview to 3D Printing Real Steel Parts **.

Neglect plastic toys. Envision printing a rocket engine part, a custom clinical implant, or a super-strong brace for your race cars and truck. That’s the real manage steel 3D printing. It sounds like sci-fi, however it’s taking place now in factories and workshops. How does it in fact work? Let’s simplify without the confusing jargon.

Initially, you need an electronic style. Think about it like a super-detailed blueprint made on a computer. This data informs the printer exactly what to construct, layer by small layer. This is your beginning point. Everything relies on getting this digital version right.

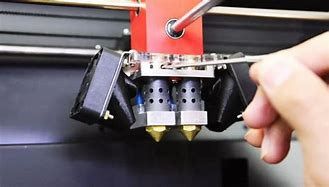

Now, the printing itself isn’t such as squirting molten metal from a nozzle. Usual techniques utilize metal powder, exceptionally great dirt. Believe powdered sugar, however constructed from steel, titanium, or aluminum. The printer spreads a thin layer of this powder onto a build system. Then, a powerful laser or electron light beam zaps specific areas, thawing the powder together based upon your style. This takes place one slim layer at a time. The platform reduces a little, a brand-new powder layer goes on top, and the laser strikes again, fusing the new layer to the one below. This repeats over and over, developing your component from all-time low up.

Another means utilizes steel powder combined with an unique binding representative. The printer sprays this mixture like ink, specifically placing it. After printing, the whole “green” component goes into a heating system. The warm burns away the binder and sinters the metal powder fragments, solidifying the part. This approach is typically less costly but might need additional finishing work.

A 3rd method uses metal wire rather than powder. Think of a state-of-the-art soldering iron. The printer feeds steel cord to a focused heat resource, thawing it and exactly transferring drops to construct the form. This can be much faster for majorities and uses much less product.

So, you’ve obtained your printed metal component. It normally isn’t prepared to make use of right off the printer. It might look a bit harsh. It frequently needs assistance structures eliminated. These assistances hold looming components during printing. Eliminating them takes careful work. Then, the component usually returns right into a heating system. This last warmth therapy, called annealing, soothes interior tensions. It makes the steel stronger and much more dependable. Some components likewise obtain machining or polishing for a best coating.

This technology isn’t magic. It has restrictions. The equipments cost a lot. The steel powders are costly and need mindful handling. Safety is crucial; breathing metal dust misbehaves news. Designing for steel printing requires special understanding. Not every shape prints well. But the opportunities are significant. Creating facility, lightweight shapes difficult to make any other way? That’s the genuine power. Making custom-made parts without pricey molds? That’s changing just how things obtain constructed. Repairing high-value components by adding brand-new steel? That’s saving cash and time.

(how to 3d print metal parts)

Steel 3D printing is opening up doors. It’s allowing engineers dream up wild new styles. It’s allowing producers build points faster and smarter. It’s turning electronic ideas into real, solid steel objects. The future of making things is obtaining printed, one tiny layer of steel at a time.