Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

Overview of SJ35 single screw 3D printing filament extrusion machine and dryer

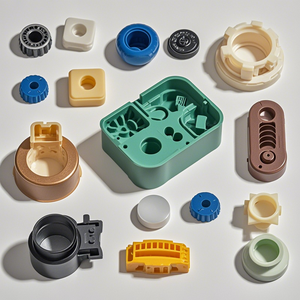

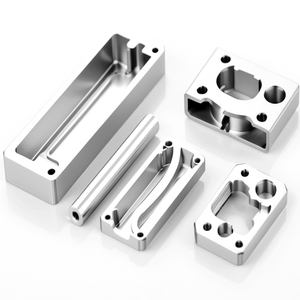

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of SJ35 single screw 3D printing filament extrusion machine and dryer

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(SJ35 single screw 3D printing filament extrusion machine and dryer)

Specification of SJ35 single screw 3D printing filament extrusion machine and dryer

Here’s the requirements for the SJ35 single screw filament extrusion equipment and dryer. This machine makes 3D printing filament. It dries plastic pellets first. After that it extrudes them right into filament. The maker integrates drying and extrusion in one device.

The extruder makes use of a single screw layout. The screw size is 35mm. It takes care of usual plastics like PLA, ABS, PETG. The barrel heats up the plastic. 3 heaters control the temperature precisely. Thermocouples keep track of warm. This ensures secure melting. The equipment pulls the melted plastic via a die. This creates the filament strand.

A powerful motor transforms the screw. A gearbox provides solid torque. This pushes the plastic regularly. You adjust the screw speed. This controls the filament output rate. The maker makes filament from 1.75 mm to 3.00 mm size. You change the die dimension for different sizes.

The clothes dryer rests above the extruder. It dries the plastic pellets prior to extrusion. Wetness damages filament top quality. The clothes dryer removes moisture. It utilizes heated air. A fan flows the warm air inside the chamber. You established the drying temperature level. The temperature variety appropriates for many plastics. The chamber holds a great quantity of pellets. It feeds dried out pellets straight into the extruder hopper. This maintains the procedure continual.

The control panel takes care of everything. Digital displays show temperatures. You see the screw speed. You see the dryer temperature. Separate controls adjust the extruder heating units. You adjust the dryer warmth. You established the electric motor speed. Safety features shield the equipment. It stops if points get as well warm. The device framework is sturdy steel. It supplies stable operation. The impact is portable. It fits well in workshops.

(SJ35 single screw 3D printing filament extrusion machine and dryer)

Applications of SJ35 single screw 3D printing filament extrusion machine and dryer

The SJ35 solitary screw extrusion maker makes 3D printing filament. It collaborates with a dryer unit. This configuration is useful for lots of tasks. Individuals use it to reuse old plastic. Scrap prints or fell short parts can be ground into tiny items. The SJ35 melts this plastic down. It pushes the melted plastic via a little opening. This makes new filament. The dryer is necessary right here. Damp plastic makes bad filament. Bubbles create. The filament breaks quickly. The dryer removes wetness before melting. This makes solid, smooth filament.

You can make custom-made filament too. The SJ35 manages lots of plastic types. PLA, ABS, PETG are common selections. You can include shades or special powders. Additives like wood fibers or steel powders change the filament. This allows you develop distinct materials. Perhaps you want sparkly filament. Possibly you require filament that flexes quickly. The SJ35 aids you do this. The clothes dryer makes certain ingredients stay dry. Wet additives trigger troubles throughout printing.

Specialty filaments commonly require drying. Nylon absorbs water quickly from the air. Wet nylon prints poorly. It strings and warps. The dryer keeps nylon completely dry before extrusion. This is essential for good results. The very same relates to various other sensitive materials like PVA.

Local business discover the SJ35 valuable. They can generate filament as needed. They do not need huge supplies. They make exactly what a customer wants. Details color, certain product. Enthusiasts additionally use it. They trying out new filament blends. They conserve cash recycling their own plastic waste. The dryer belongs to this process every single time. It assures the material going into the extruder prepares. This avoids lost plastic and failed prints later. The maker provides control over the filament making procedure.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of SJ35 single screw 3D printing filament extrusion machine and dryer

Here are 5 FAQs for the SJ35 Single Screw 3D Printing Filament Extrusion Machine and Dryer:

What materials can the SJ35 handle?

The SJ35 works with common plastic pellets. Use PLA, ABS, PETG, or TPU. Avoid very hard plastics. Match the material to your needs. The machine melts pellets consistently.

Why is the dryer important?

Moisture ruins filament. Wet pellets make bubbles or breaks in the final filament. The dryer heats the pellets first. It removes moisture effectively. Dry pellets mean smooth, strong filament output.

How often does the machine need cleaning?

Clean the screw and barrel after each material change. Leftover plastic causes jams or color mixing. Check the heaters and sensors monthly. Basic cleaning prevents most problems. Keep the area dust-free.

Is the machine safe to operate?

The machine gets very hot. Never touch the nozzle or heater areas during operation. Wear heat-resistant gloves when near hot parts. Follow all electrical safety rules. Read the manual before starting.

What if my filament has lumps or breaks?

Lumps usually mean wet material. Dry your pellets longer. Check the dryer temperature settings. Breaks can happen if the puller speed is wrong. Adjust the speed slower. Also check for a clogged nozzle. Clean it carefully.

(SJ35 single screw 3D printing filament extrusion machine and dryer)