Discover a professional 3D printing powder supplier

Title: Metal Magic: Transforming 3D Prints right into Shiny Metallic Treasures

(how to make 3d printed objects look metal)

1. Just What is Metal Finishing for 3D Prints? .

Think of it like offering your plastic development a head-to-toe makeover. Metal ending up means using different tricks to make your 3D published object appearance, feel, and sometimes also beam like genuine metal. It conceals the layer lines. It conceals the plastic texture. It alters the color entirely. The objective is misleading the eye. Individuals see plastic, however their mind signs up steel. This isn’t nearly shade. Real steel has a certain depth, a details luster, often also a great texture. Good completing mimics all that. It turns a basic print into something that looks expensive, durable, and incredibly professional. It’s the secret sauce in between an enthusiast job and a costs model or item.

2. Why Inconvenience Making Plastic Look Metallic? .

The reasons are solid and functional. First, looks issue. A metallic coating screams quality. It makes your job look much more beneficial and professional than raw plastic. This is essential for prototypes revealed to clients or end products indicated for sale. Second, it conceals blemishes. Sanding marks, layer lines, little print mistakes– an excellent metallic layer covers them up wonderfully. Third, it opens up design doors. Perhaps you need the look of brass for a steampunk gadget. Perhaps you desire sleek light weight aluminum for a technology accessory. Genuine steel printing is expensive and facility. Finishing plastic is method less expensive and quicker. Fourth, it feels much better. Specific finishes add weight and a cool, smooth touch. This enhances the individual experience. Ultimately, it shields the plastic below from square one and UV light. So, it’s not just vanity; it’s smart style and security.

3. How Do You Really Achieve That Convincing Metal Look? .

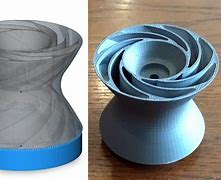

Numerous courses result in metal magnificence. Your choice depends on the preferred effect and your effort degree. Begin with fining sand. Smooth the print thoroughly. Start coarse, then transfer to fine grits. This eliminates layer lines. Next, use primer. Filler primer loads tiny scrapes. It produces a consistent base. Now, the fun component: adding metal. Right here are popular techniques:.

Metallic Paints & Sprays: Easiest and fastest. Usage spray paints specifically labeled “metal.” Brands like Rust-Oleum Metallics function well. Apply slim, even layers. Allow dry between layers. Enthusiast gently with very great steel wool for added sparkle. For brush-on, try model paints like Vallejo Metal Shade.

Scrub ‘n Aficionado: This is a waxy paste. Use a tiny amount with a soft fabric. Rub it vigorously onto the surface area. Buff to a high shine. Amazing for highlights, information, and antiqued appearances. Great on textured prints.

Electroplating: This layers the plastic in genuine steel. Initially, make the surface area conductive. Use an unique conductive paint or graphite powder. After that, immerse the things in a plating solution. Pass an electrical current via it. Metal ions adhere to the surface area. Outcomes are stunning– real copper, nickel, also chrome. Requirements more equipment and safety and security equipment.

Metal Leafing: Use slim sheets of real metal (like gold or silver leaf) utilizing glue. Develops an extremely genuine, elegant coating. Breakable but impressive.

Cold Spreading: Mix steel powder (bronze, light weight aluminum, and so on) right into material. Cover the print or cast parts. After curing, gloss. The things feels hefty and appears like solid steel.

4. Where Can You Utilize These Metallic-Finished Prints? .

The applications are almost endless. Assume models. Program clients a “steel” part without the expense of machining. Item designers like this. Picture custom fashion jewelry. Develop complex necklaces or rings that appear like refined silver or gold. Perfect for cosplay. Develop shield, weapons, or gadgets with authentic metal sheen. Design makers profit hugely. Craft realistic engine components, range automobiles, or historical artifacts. Home decoration obtains a boost. Make light bases, vases, or sculptures that appear like brass or iron. Technology accessories radiate. Design phone stands, headphone owners, or key-board frameworks with an aluminum or steel appearance. Even useful components like custom-made knobs, gears, or units gain a costs feel. Generally, any kind of job requiring a high-end, resilient, or simply eye-catching steel appearance can utilize this strategy.

5. Metal Completing Frequently Asked Questions: Your Inquiries Addressed .

Allow’s take on typical concerns:.

Does it add considerable weight? Usually not much. Repaint and Massage ‘n Enthusiast add minimal weight. Cold casting adds the most. Electroplating includes a thin layer, so weight rise is small. The really feel changes more than the real weight.

Just how durable is the coating? It varies. Basic spray paint can chip. Electroplating is very durable. Cold casting is tough. Utilizing a clear top coat (gloss or matte) secures metal paints and Scrub ‘n Aficionado substantially. Handle completed pieces with sensible treatment.

Can I achieve different metal types? Absolutely! Paint shades cover brass, bronze, copper, steel, light weight aluminum, gold, silver. Rub ‘n Buff can be found in many tones. Electroplating deals certain metals. Cold casting usages various powders. Choose the method matching your target metal.

Is it secure? Constantly operate in a well-ventilated location. Put on handwear covers and a respirator when fining sand, spraying paints, or making use of chemicals (like layering solutions or materials). Review product safety sheets.

Which filament functions best? PLA and ABS are most common. They sand conveniently and take paint well. Materials (SLA/DLP) give incredibly smooth surfaces, optimal for plating or high-gloss surfaces. Avoid extremely versatile filaments; they can crack surfaces. Sanding is vital despite material.

(how to make 3d printed objects look metal)

Can I plate any kind of plastic? Mainly, yes. However the surface must be completely smooth and tidy. Conductive layer must adhere well. Facility shapes may have plating disproportion. Easy forms produce best plating outcomes.