Discover a professional 3D printing powder supplier

West Coast Wonders Unlocking Metal Magic with 3D Printing Pioneers

(who does 3d metal printing on west coast)

The West Coast buzzes with innovation. It’s a land where imagination meets metal. 3D metal printing thrives here. This isn’t science fiction. It’s real manufacturing magic. Companies across California Oregon Washington are leading this charge. They transform digital dreams into solid metal reality. This technology builds complex parts layer by layer. It breaks old limits. Let’s explore this fascinating world. Discover the pioneers reshaping how we make things.

1. What is 3D Metal Printing Exactly

3D metal printing creates solid objects from metal powders or wires. Think of it like building with digital Legos. A computer model guides the process. High-powered lasers or electron beams melt metal precisely. Layers fuse together. Slowly a complete part emerges. This differs from cutting metal away. It adds material only where needed. Common methods include Selective Laser Melting and Direct Metal Laser Sintering. These techniques use fine metal powders. Other methods like Directed Energy Deposition use metal wire. The result is dense strong metal components. Complexity comes free. Intricate designs impossible with old methods become simple.

2. Why West Coast Companies Embrace This Technology

The West Coast offers unique advantages. First access to top tech talent matters. Universities like Stanford Caltech feed innovation hubs. Second venture capital flows freely here. Startups get funded quickly. Third industries here demand cutting-edge solutions. Aerospace giants in Seattle need lightweight rocket parts. Medical device firms in Silicon Valley require custom implants. Hollywood studios seek detailed props. Automotive innovators want complex car components. Speed is crucial. 3D printing delivers prototypes in days not months. Customization is easy. Each part can be unique. Waste drops dramatically. Material use becomes efficient. Sustainability goals align perfectly. Local production cuts shipping delays. Supply chains grow shorter stronger.

3. How the Metal Printing Process Actually Works

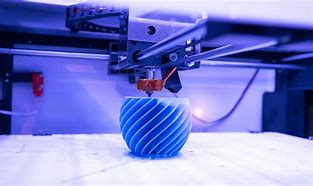

The journey starts with a 3D digital file. Software slices this model into ultra-thin layers. Inside the printer a metal powder bed or wire feed system prepares. For powder systems a recoater spreads a thin layer evenly. A laser beam scans the layer. It follows the slice pattern exactly. Metal particles melt fuse instantly. The build platform lowers slightly. Another powder layer spreads. The laser repeats its dance. Layer builds upon layer. After printing the part cools inside the machine. Technicians remove excess powder carefully. Support structures get detached. Post-processing often includes heat treatment. This relieves internal stresses. Machining or polishing achieves final surface finishes. Quality checks ensure precision. Every step demands expertise.

4. Applications Changing Industries Right Now

3D metal printing tackles real-world challenges. Aerospace soars ahead. Boeing Airbus print lightweight turbine blades. Fuel efficiency improves dramatically. Complex fuel nozzles integrate multiple parts into one. Medical breakthroughs happen daily. Dental labs produce custom crowns overnight. Surgeons implant patient-specific hip replacements. Porous structures encourage bone growth. Automotive leaders accelerate innovation. Electric car makers print lightweight battery components. Custom cooling channels boost performance. High-performance racing teams create track-ready parts fast. Tooling transforms. Molds with conformal cooling channels cut production time. Energy sector benefits. Geothermal drill heads withstand extreme conditions. Even art finds expression. Sculptors craft intricate metal pieces previously unthinkable. Consumer goods evolve. Custom jewelry durable phone cases emerge.

5. FAQs About West Coast 3D Metal Printing Services

Many questions arise about this technology. Here are clear answers.

Question How strong are these printed metal parts

Answer Extremely strong. Properly printed parts match or exceed traditional metal strengths. Materials like titanium stainless steel perform reliably. Fatigue resistance is excellent.

Question What metals can be printed

Answer Many options exist. Titanium alloys are popular for aerospace medical. Stainless steel serves industrial needs. Aluminum offers lightness. Nickel superalloys handle extreme heat. Copper gold silver work too.

Question How much does it cost

Answer Costs vary widely. Small simple parts cost less. Size complexity material affect price. Initial setup has fixed costs. Per-part cost drops in larger batches. Often cheaper than machining complex one-offs.

Question How long does printing take

Answer Time depends on part size complexity. Small items finish in hours. Larger intricate parts take days. Post-processing adds time. It’s still faster than traditional tooling for prototypes.

Question Can I print large objects

Answer Yes but size has limits. Printer build volumes define maximums. West Coast shops offer machines with large capacities. Very big parts print in sections. Expert welding joins them seamlessly.

Question Is the surface finish smooth

Answer As-printed surfaces show slight texture. It resembles fine sandpaper. Most applications require post-processing. Polishing machining create mirror finishes. It depends on the part’s final use.

Question Who are the top West Coast providers

Answer Leaders include established players and startups. Look for companies with diverse metal capabilities. Check their industry experience. Review client testimonials. Visit facilities if possible. Many offer online quoting systems.

(who does 3d metal printing on west coast)

The West Coast remains a hotbed for this advanced manufacturing. Its spirit of innovation ensures continued leadership. Businesses here push boundaries daily. They turn metal dreams into tangible reality.