Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

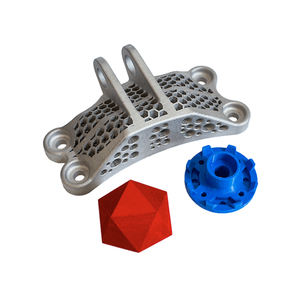

Overview of Custom Plastic Toys Parts Rapid 3D Printing Prototype Service Prototyping

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of Custom Plastic Toys Parts Rapid 3D Printing Prototype Service Prototyping

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(Custom Plastic Toys Parts Rapid 3D Printing Prototype Service Prototyping)

Specification of Custom Plastic Toys Parts Rapid 3D Printing Prototype Service Prototyping

Required plastic toy parts made fast? Our fast 3D printing solution constructs customized models quickly. Obtain physical parts in your hands quickly. This speeds up your style procedure.

We print making use of hard plastics perfect for plaything components. Pick from several product kinds. Each material has various staminas and feels. Some are adaptable like rubber. Others are difficult and rigid. Some even really feel smooth. Pick the very best plastic for your specific plaything component.

Our machines construct components really accurately. Fine information turn up clearly. Small features and complicated shapes are no problem. You see precisely how your last plaything part will certainly look and fit. Check the layout works before big manufacturing.

Getting going is basic. Send us your 3D style documents. Common layouts like STL work fine. Our team examines it. We verify every little thing looks great. Then printing starts as soon as possible. We transform styles right into actual components quickly.

This solution conserves you time and money. Avoid pricey tooling expenses for prototypes. Test different concepts rapidly. Make adjustments easily. Improve your toy design much faster. Obtain feedback early. Enhance your item before dedicating to mold and mildews.

You obtain long lasting, functional models. Check them for function. Inspect how parts relocate together. See if they are strong sufficient for play. Examine the feel and look. Ensure kids will certainly like it.

(Custom Plastic Toys Parts Rapid 3D Printing Prototype Service Prototyping)

Applications of Custom Plastic Toys Parts Rapid 3D Printing Prototype Service Prototyping

Creating brand-new plastic toy parts takes job. You require real versions to examination. Rapid 3D printing prototyping solves this problem. It develops custom-made plastic plaything items fast straight from your electronic data. Neglect sluggish, expensive conventional tooling.

This solution is ideal for plaything designers and inventors. Obtain a physical part in your hands swiftly. See exactly how your brand-new action number joint moves. Examination if your building block snaps with each other appropriate. Check the size and really feel before devoting to mass production. Errors are cheap to repair early.

The process is simple. You send your 3D style documents. Specialists evaluate it for printability. They pick the most effective plastic material and printing modern technology. Usual selections are resilient materials or nylon-like plastics. Parts publish layer by layer with high accuracy. Shades are feasible also. Assistance frameworks hold delicate attributes throughout printing. These get removed carefully after.

Rate is the most significant advantage. Obtain prototypes in days, not weeks or months. This allows you test ideas quickly. Boost your layout based upon genuine responses. Program prospective partners or financiers a working design. Speed up your whole development cycle significantly.

Expense financial savings are important. No need for expensive steel mold and mildews in advance. Print only the parts you need today. Make style changes conveniently. Just update the digital file and print once again. This flexibility is essential for development. You can try multiple variations rapidly.

Test functionality effectively. Set up relocating parts. Examine clearances. See exactly how long lasting the piece remains in play. Ensure security standards are satisfied. Validate the appearance and shade under genuine light. Obtain youngsters to attempt it out. Real-world testing captures troubles early.

Material choices matter. Suit the properties of the final manufacturing plastic. Get components that are strong enough. Versatile enough. Safe enough. Accomplish the ideal surface finish. Smooth or distinctive as required. Good prototypes provide reliable results.

This service bridges the space in between concept and production. Relocate from principle to tangible component effectively. Reduce risks prior to purchasing tooling. Bring much better plastic toys to market quicker.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Custom Plastic Toys Parts Rapid 3D Printing Prototype Service Prototyping

Here are five common questions about our custom plastic toy parts rapid 3D printing prototype service:

What plastic materials can you use? We offer several safe plastics. Common choices are durable ABS and tough PLA. We also use strong nylon and flexible TPE. Need something special? Just ask. We focus on materials safe for toy testing and handling.

How fast is the turnaround? It’s very quick. Simple designs often ship in 1-3 days. Complex parts might take 3-5 days. We start printing almost immediately after you approve the quote and design. Need it faster? Rush options exist.

Is 3D printing strong enough for toy parts? Yes, definitely. Modern 3D printers create robust prototypes. We choose materials suited for toy function and feel. Parts handle assembly checks, fit tests, and basic play testing well. They aren’t meant for long-term heavy use, but work perfectly for prototypes.

How much does it cost? Cost depends mainly on the plastic used and the part’s size. Small, simple parts are very affordable. Larger or complex designs cost more. We give you a clear price quote upfront. There are no hidden fees. Prototyping saves money compared to traditional tooling.

How good is the surface finish? The finish is good for prototypes. You see the actual part shape clearly. Layers might be slightly visible. We offer different finishing levels. Basic is fine for functional checks. Smoother options are available for looks. Paint or sand it yourself easily.

(Custom Plastic Toys Parts Rapid 3D Printing Prototype Service Prototyping)