Discover a professional 3D printing powder supplier

Title: Steel Magic: Your Front Row Seat to 3D Printing’s Coolest Trick

(how it’s made 3d metal printing episode 1)

Blog site: .

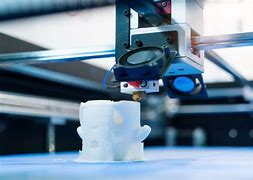

Visualize structure facility steel objects, layer by small layer, directly from a digital blueprint. Forget typical hammers and molten pours. This is 3D steel printing. It seems like science fiction made real. Episode 1 of “Just how It’s Made: 3D Steel Printing” draws back the curtain. Let’s explore this fascinating technology.

Key Product Keywords: 3D Metal Printing.

1. Exactly What is 3D Steel Printing? .

3D steel printing constructs strong steel parts straight from a computer system file. Think of it as high-tech welding regulated by a super-precise robotic. Rather than removing material like machining, it includes product only where required. This procedure is additionally called Metal Ingredient Manufacturing (AM).

Numerous methods exist. One of the most common one uses a powerful laser or electron light beam. This beam thaws great metal powder, fusing it factor by point. Another technique sprays a binder onto metal powder, gluing it with each other prior to last baking. A third method uses a steel cable fed into a high-energy warm source, melting it as it develops. Each layer bonds to the one below. Slowly, a complete 3D metal item emerges from nothing.

The magic depend on its accuracy and flexibility. It creates shapes impossible with old approaches. Inner channels, complex latticeworks, natural types– all end up being possible. This is manufacturing, reimagined.

2. Why Select 3D Steel Printing Over Old Ways? .

Why trouble with this new technology? It solves troubles standard manufacturing can’t handle.

Complexity costs little added. Making a very complex part with CNC machining or spreading is tough. Typically it’s difficult. 3D steel printing handles intricacy conveniently. The expense is almost the same as making an easy block.

It throws away less material. Conventional methods often begin with a huge block of steel. They reduced a lot of it away. This produces massive scrap stacks. 3D printing makes use of just the steel needed for the part itself. This saves product and money.

Prototyping is lightning quickly. Designing a new part? Obtain a metal prototype in days, not weeks or months. This quickens growth cycles greatly.

Customization is simple. Need a special dental implant for a client? A specialized tool for a particular job? 3D printing makes one-offs functional. Automation rules do not apply here.

Performance gets a boost. Designers can maximize parts for toughness and weight. They can produce interior structures that improve fluid circulation or warmth dissipation. This leads to lighter, more powerful, better-performing elements.

3. How Does 3D Metal Printing Really Work? (The Laser Powder Bed Method) .

The laser powder bed fusion technique is the most prevalent. Here’s exactly how it typically functions:.

One: Prepare the Digital Version. Designers develop the component utilizing 3D CAD software. Special software program pieces this 3D model right into ultra-thin horizontal layers. This produces a digital construct strategy.

2: Prepare the Machine. An employee loads the printer’s feed chambers with great metal powder. Typical powders include titanium, stainless-steel, light weight aluminum, and nickel alloys. The construct chamber platform decreases a little. A recoating blade spreads out a thin, also layer of powder over the construct platform.

Three: Thaw the Powder. A high-power laser beam scans across the powder layer. It complies with the form of the very first piece of the digital design. Where the laser hits, the metal powder thaws and fuses strong. The laser moves incredibly quick, mapping the pattern.

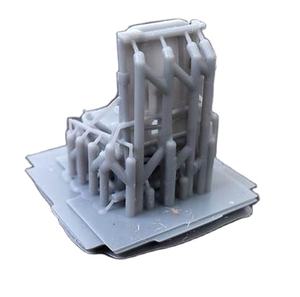

4: Lower, Recoat, Repeat. The develop platform reduces by the density of one layer. The recoating blade spreads one more fresh layer of powder over the previous one. The laser then melts this new layer, fusing it to the layer listed below. This cycle repeats hundreds or hundreds of times.

Five: Cool and Clean. After the last layer is integrated, the entire construct chamber cools off. Employees carefully remove the build system. Excess, unsintered powder borders the printed part. This powder gets collected and recycled. The part goes through cleaning. Assistance frameworks are gotten rid of. Post-processing like warm treatment or machining could occur following. The final steel component is ready.

4. Where is 3D Metal Printing Utilized Today? (Real-World Applications) .

This technology isn’t just for labs. It’s changing markets today.

Aerospace leads the fee. Airplanes and rockets need strong, light-weight parts. 3D printing creates complicated engine elements, fuel nozzles, and lightweight architectural braces. Weight cost savings right here equate straight into gas performance.

Clinical implants are life-altering. Surgeons make use of 3D printed titanium hips, knees, and back cages. These implants completely match an individual’s special makeup. Porous structures encourage bone growth. This improves healing and convenience.

The auto sector is adopting it. High-performance autos utilize printed components for engines, transmissions, and customized parts. Racing teams leverage it for fast prototyping and specialized components.

Tooling and manufacturing benefit considerably. Factories make use of 3D printed jigs, fixtures, and personalized devices. These are made quicker and more affordable than conventional methods. They enhance assembly line effectiveness.

Power market applications are expanding. Generator elements, warmth exchangers, and specialized valves for oil, gas, and power generation are being printed. Complex inner geometries boost performance.

Even durable goods are emerging. Premium watches, bespoke fashion jewelry, and personalized bike components are starting to appear. As costs reduce, anticipate to see even more.

5. Frequently asked questions: Your Burning Concerns Concerning 3D Metal Printing Addressed .

Is 3D published steel strong? Yes. Printed components often match or surpass the strength of actors or created steel. Correct printing and post-processing are essential. The product buildings are exceptional.

How expensive is it? It’s extra expensive per part than mass production methods like casting or marking. For intricate parts, prototypes, or reduced volumes, it can be economical. Prices are falling as technology enhances.

What steels can be published? Numerous! Typical ones: Titanium alloys (strong, lightweight), Stainless Steels (versatile), Aluminum alloys (lightweight), Nickel-based superalloys (heat immune), Cobalt-Chrome (biocompatible for implants), Device Steels. New materials are constantly being established.

How long does printing take? It depends on part dimension and intricacy. Small components take hours. Larger, complicated parts can take days. It’s slower than automation however faster than machining complex models.

Is it safe? Industrial printers run in secured chambers. Operators take care of great steel powders thoroughly. Proper ventilation and safety gear are necessary. The powders can be combustible. Security methods are rigorous.

Can it make large things? Yes, printers are growing. Some can currently construct parts over a meter in dimension. Printing very large objects is still tough and pricey. It’s boosting quickly.

(how it’s made 3d metal printing episode 1)

Do published components need completing? Generally. Components come out with a somewhat harsh surface area. Assistance structures need elimination. Heat therapy relieves interior tensions. Machining could be required for crucial surfaces. Finishing belongs to the process.