Discover a professional 3D printing powder supplier

Steel 3D Printing: From Science Fiction Dream to Factory Floor .

(can metal be 3d printed)

You have actually seen plastic playthings made layer by layer. But metal? Can you actually print something strong, intricate, and metallic right from a computer system documents? The answer is a powerful yes. Steel 3D printing isn’t simply feasible; it’s changing exactly how we build whatever from rocket engines to custom medical implants. Fail to remember the sluggish work of typical machining. This is about producing difficult forms with extraordinary strength, straight from digital designs. Let’s dive into this interesting world.

1. What is Steel 3D Printing? .

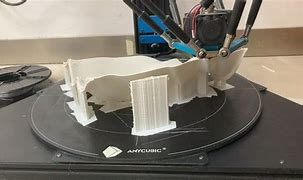

Steel 3D printing builds solid items layer by layer utilizing steel. It’s not ink theoretically. Think of it extra like welding tiny bits of metal together with severe precision. A computer system cuts a 3D design into thin layers. The printer after that creates each layer one on top of the various other. Various techniques exist. Some use powerful lasers or electron beams to melt fine metal powder. Others bind powder together with glue after that cook it solid. One more approach squirts liquid metal like a very specific, modern glue weapon. The result? Complicated metal components you often can not make differently. It transforms electronic dreams into tangible, functional metal truth.

2. Why Pick Steel 3D Printing? .

Traditional metalworking subtracts product. You start with a big block and cut away what you do not need. Steel 3D printing includes product just where required. This saves pricey metal. It additionally allows styles impossible with drills or mills. Believe detailed interior networks for cooling inside an engine component. Believe lightweight, strong structures simulating bone. Need a special part quick? 3D printing can avoid weeks of tooling setup. It succeeds at prototypes, personalized one-off components, and complicated low-volume manufacturing. The layout flexibility is immense. You optimize parts for stamina and weight, not simply for ease of machining. This causes much better efficiency. It makes it possible for customization at degrees standard approaches can not touch.

3. Just How Does Metal 3D Printing Work? .

Several essential approaches dominate steel printing. Powder Bed Combination is common. A slim layer of fine steel powder spreads throughout a construct plate. A high-power laser or electron beam of light checks the plate. It melts the powder specifically where the part’s very first layer should be. The plate reduces slightly. An additional powder layer spreads. The laser thaws this new layer, fusing it to the one listed below. This repeats up until the component is full. Binder Jetting is various. It spreads out powder then publishes a liquid binding agent to adhesive particles together layer by layer. The “eco-friendly” part then goes into a heating system. The binder burns away, and the metal fragments fuse. Directed Energy Deposition (DED) functions like welding. A nozzle feeds metal powder or cord right into a thaw pool created by a laser or plasma arc. This builds up product straight. Steel Extrusion pushes a filament loaded with metal powder and binder via a nozzle, layer by layer. The component is later on sintered to eliminate the binder and fuse the metal. Each approach has strengths. The selection depends upon the material, component size, and required buildings.

4. Metal 3D Printing Applications .

This technology is not a laboratory curiosity. It’s constructing actual points. Aerospace enjoys it. Printing complex, light-weight wind turbine blades and fuel nozzles conserves weight and enhances effectiveness. Rockets fly with published burning chambers. Medication uses it for custom-made implants. Think titanium jawbones or hip sockets flawlessly shaped for one person. Dental experts publish crowns and bridges much faster. Automotive business print models swiftly. They make custom-made jigs and devices for the production line. High-performance auto racing components are published. Energy firms publish complex warmth exchangers and oil field elements. Jewelers create elaborate designs difficult to cast. Craftsmens make unique sculptures. Even durable goods advantage. Assume premium custom bike components or custom watch parts. The applications expand daily.

5. Metal 3D Printing FAQs .

(can metal be 3d printed)

Individuals ask usual concerns. Is it strong? Absolutely. Properly published parts fulfill or exceed the toughness of cast or machined equivalents. They can be heat-treated for even far better performance. Is it expensive? Yes, makers and products cost more than plastic printers. The worth comes from style freedom, less waste, and faster production for complex components. It repays where standard approaches struggle. What metals can be published? Numerous. Titanium is prominent for its toughness and light weight. Stainless-steel alloys are commonly made use of. Device steels, nickel superalloys (like Inconel), aluminum, cobalt chrome, also precious metals like gold and silver can be printed. Are the components smooth? The surface finish is rougher than machined steel. Components typically require ending up like sanding or polishing. Assistance structures are usually needed during printing. These must be eliminated after. Exactly how large can components be? Printers vary from desktop dimension to machines constructing components meters long. Size is restricted by the printer’s develop chamber. Huge parts can be published in sections and welded. Is it secure? Managing great metal powder requires care. Printing takes place in sealed chambers with inert gas to avoid fires. Operators comply with stringent security methods.