Discover a professional 3D printing powder supplier

Metal Powder: The Secret Active Ingredient in Every 3D Steel Print? .

(does all 3d metal printing use metal powder)

Consider developing something remarkable, layer by little layer, right prior to your eyes. That’s the magic of 3D printing. Metal objects pop out of printers, intricate shapes impossible by typical techniques. Yet how does raw metal get turned into these complex parts? The response often depends on a surprisingly straightforward beginning factor: great steel powder. This raises the huge inquiry: Is metal powder absolutely important for every single sort of 3D steel printing?

1. What is Metal Powder in 3D Printing? .

Steel powder is precisely what it sounds like: tiny grains of steel. Think super-fine sand, however made completely of materials like titanium, stainless-steel, aluminum, nickel alloys, or perhaps rare-earth elements like gold. This powder isn’t rugged like beach sand. It’s unbelievably fine, often with bits smaller sized than the size of a human hair. Uniformity is vital. The powder requires to move efficiently, like flour, to spread out uniformly inside the 3D printer. Fragment size and shape straight influence the last top quality of the printed component. Round particles usually flow and compact best. Different steels call for various powder residential properties. The powder forms the literal building blocks of the final steel things. It’s the raw material changed.

2. Why is Steel Powder Utilized for 3D Steel Printing? .

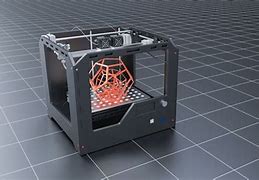

Steel powder is the foundation for the most common and powerful steel 3D printing methods. The core reason is how these printers function. Processes like Careful Laser Melting (SLM) or Direct Steel Laser Sintering (DMLS) make use of a high-powered laser. This laser exactly melts small spots of metal powder, fusing them with each other. Powder permits this determine accuracy. The laser can focus on a certain area within a slim layer of powder. Making use of strong metal rods or sheets wouldn’t work the same way. Powder also makes it possible for unbelievable intricacy. Assistance frameworks can be printed within the powder bed itself. These assistances hold overhanging components throughout printing. The unused powder acts like an all-natural assistance material. After printing, you simply comb away the loosened powder. This flexibility permits designs with internal networks, lattices, or shapes that machining merely can not attain. Powder supplies the adaptability and accuracy required.

3. How Do Printers Make Use Of Steel Powder to Develop Components? .

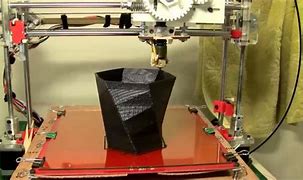

The process is remarkable. Visualize a printer with a build chamber. Inside this chamber rests a construct platform. A thin layer of metal powder, maybe 20-50 microns thick (thinner than paper), is spread evenly throughout this platform. This happens immediately making use of a recoater blade or roller. Next, an effective laser checks across the powder layer. The laser complies with the exact cross-section of the part being published for that certain layer. Wherever the laser strikes, the steel powder thaws and merges with each other. The system after that lowers slightly. Another fresh layer of powder is spread on the top. The laser again thaws the brand-new layer, likewise bonding it to the layer below. This cycle repeats: spread powder, melt pattern, reduced platform. Layer by layer, the solid metal part expands upwards, embedded within the surrounding loosened powder. As soon as finished, the whole build chamber cools down. Workers then get rid of the printed part, still covered in extra powder. They very carefully remove the component and clean off all the excess powder. Often additional warm therapy is needed for stamina.

4. Metal Powder Printing Applications: Where It Beams .

This innovation isn’t just for prototypes anymore. It’s transforming real-world production. Aerospace firms greatly utilize it. They print facility, light-weight components for jet engines and spacecraft. Believe fuel nozzles with elaborate inner air conditioning channels impossible to machine. The medical area benefits hugely. Specialists implant tailor-made titanium bone substitutes or back cages. These fit a patient’s composition completely. Dental professionals develop crowns and bridges directly from biocompatible steel powders. The auto market uses it for high-performance racing components. Think custom-made pistons or turbocharger elements. Toolmakers print mold and mildews with conformal air conditioning channels. These channels adhere to the mold’s shape very closely. Cooling takes place much faster, reducing production time. Jewelers produce complex designs in gold, platinum, or silver powder. Also commercial markets use it for specialized shutoffs, warm exchangers, and pump components. The ability to make solid, complicated, customized metal components promptly is a game-changer.

5. Steel Powder Printing Frequently Asked Questions: Your Questions Addressed .

Does ALL metal 3D printing use powder? Mostly, yes. The dominant industrial approaches (SLM, DMLS, EBM) absolutely depend on metal powder. They are the workhorses. However there are a few specific niche exceptions. Some printers make use of metal wire fed right into an effective power source (like an electron beam of light or laser) to thaw and deposit product. This is called Directed Power Deposition (DED). One more method bonds metal particles together using a binder, then sinters the part later on. However, powder-based approaches are even more typical for creating strong, thick, final-use steel parts. For useful objectives, metal powder is king.

Is the powder pricey? Yes, frequently. Making top quality, consistent metal powder is facility. The atomization process (transforming molten metal into fine powder) calls for specific devices. Managing great metal powders securely adds cost. Powder price is a considerable factor in the total print rate.

Is unused powder thrown away? Excellent news! Many unused powder can be recycled. After a print job, the loosened powder surrounding the part is gathered. It’s sieved to remove any kind of clumps or large fragments. Fresh powder is after that combined back in for the following print. Reusing prices are high, typically over 95%. This decreases waste and price.

Are printed components as solid as created parts? They can be really solid, often also stronger in specific directions. Nevertheless, the buildings depend upon the printing procedure, the metal made use of, and the settings. Post-processing like warm therapy prevails. It assists achieve residential or commercial properties matching or going beyond conventional methods. Consistency is key.

(does all 3d metal printing use metal powder)

Is it safe to take care of metal powder? Fine metal powders need careful handling. They can position breathing dangers and are typically combustible. Printers run in sealed chambers with inert gas. Operators use safety devices when handling powder outside the device. Security protocols are essential.