Discover a professional 3D printing powder supplier

3D Printed Metal Knives: Deadly Defense or Simply Uniqueness Things? .

(can a 3d printed metal knife be a weapon)

Key Product Keywords: 3D published steel blade, weapon.

1. What Exactly is a 3D Printed Steel Knife? .

A 3D printed steel knife is precisely what it sounds like. Somebody makes it utilizing an unique kind of 3D printer. This printer builds the blade layer by layer. It uses steel powder, not plastic. Assume great grains of steel, titanium, or various other strong steels. The printer thaws this powder along with an effective laser or electron light beam. It’s called Direct Steel Laser Sintering (DMLS) or Careful Laser Melting (SLM). The outcome is a strong metal object. In this situation, it’s shaped right into a blade. This procedure is facility. It requires pricey devices and experienced drivers. It’s various from publishing a plastic toy. The last blade appears looking rough. It needs a great deal of ending up work. Somebody has to grind it, develop it, and polish it. Only after that does it appear like a usable blade. The material homes matter a whole lot. The toughness and hardness depend upon the metal powder utilized. The printing settings likewise influence the final top quality. Not all published steel is equally solid. Some parts may be weaker than others. Comprehending this technology is key. It helps us see what these knives can really do.

2. Why Would Any Individual Think About a 3D Printed Metal Knife a Weapon? .

The concept is simple. A blade is a tool. It can likewise be a weapon. A 3D published steel knife is still a blade. It has a point. It has a side. Individuals can utilize it to reduce things. Individuals can likewise use it to hurt others. This prospective exists. The metal made use of is actual metal. Steel or titanium can be sharpened. A sharp metal factor can pierce skin. A sharp metal edge can cut. So, physically, it can work as a tool. There’s one more angle. The “3D printed” component raises worries. Individuals worry about untraceable weapons. Conventional blades have identification numbers. They originate from understood factories. A 3D published knife could not leave that path. Someone could make it in your home. This concept is much more reasonable for plastic weapons. Making a steel knife by doing this is hard. It needs commercial devices. It isn’t easy or low-cost. Yet, the opportunity exists. The innovation is advancing. Gain access to might boost. This fuels the argument. Can this homemade steel blade be an unsafe weapon? The solution leans towards yes. Its physical type allows it.

3. Exactly how is a Steel Blade Really 3D Printed? .

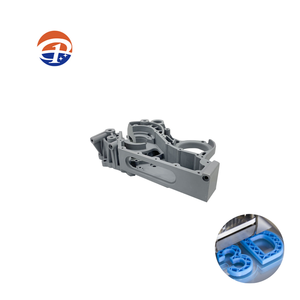

Making a real metal blade with 3D printing isn’t basic. Neglect your desktop computer plastic printer. This requires significant machinery. The procedure begins electronically. A person designs the blade on a computer. This is the CAD design. Every curve and angle is defined below. Next, the design is cut. Software program suffices right into hundreds of slim layers. This tells the printer what to construct. The printer itself is a big, sealed chamber. It’s filled with an inert gas, like argon. This stops the metal from oxidizing. A slim layer of steel powder spreads across the build platform. A high-power laser checks the platform. It follows the form of the very first piece. The laser melts the metal powder fragments. They fuse together solidly. The platform reduces a little. One more layer of powder spreads on top. The laser thaws this brand-new layer. It likewise bonds it to the layer listed below. This repeats. Layer by layer, the knife creates inside a block of powder. After printing, the whole thing cools. Employees remove the powder block. The blade is buried inside. They thoroughly dig it out. This is called “depowdering”. The published blade looks harsh. It has a rough surface area appearance. Assistance structures require getting rid of. These held it in place throughout printing. Now the effort begins. Post-processing is critical. The blade requires warmth therapy. This improves its toughness. Then comes grinding. Employees shape the blade profile. They grind the edge. They develop it carefully. Lastly, they polish it. This entire process takes hours, also days. It calls for substantial ability and devices. It’s not pressing a button.

4. Legitimate Applications: Beyond the Tool Inquiry .

Focusing only on weapons misreads. 3D printed steel blades have many legitimate uses. They display advanced production. Customization is a significant benefit. Think about a chef’s knife. Every cook has unique choices. Weight, balance, deal with form, blade geometry. 3D printing can develop the ideal personalized fit. It can make manages with ergonomic holds. It can produce blades with details curves. This is difficult with standard building. Fast prototyping matters also. Blade developers can examine originalities promptly. They publish a prototype. They evaluate it. They make modifications on the computer system. They print another one. This accelerates advancement. It causes better end products. The aerospace and medical areas utilize this technology. They make complicated, lightweight parts. Knives are an examination case. They show precision and strength. Collectors value distinct pieces. 3D printing enables artistic layouts. Assume complex patterns impossible to forge. Believe hollow structures for lowered weight. Think embedded logo designs or textures. These blades come to be functional art. Industrial cutting devices profit as well. Specialized blades for machinery can be published as needed. They fit specific requirements. The technology fixes troubles. It creates chances. Seeing it just as a tool ignores its real capacity. Advancement drives progression.

5. Frequently asked questions: Your Burning Inquiries Addressed .

Q1: Are 3D published metal knives really solid sufficient? .

A1: Yes, they can be extremely solid. It depends upon the metal powder and the printing procedure. Utilizing high-grade materials like stainless steel or titanium, printed properly, creates thick metal. Correct heat therapy after publishing increases stamina better. It can match or come close to built steel. The secret is expert printing and completing.

Q2: Can a person actually publish a metal blade in the house? .

A2: Probably not conveniently. Desktop computer metal 3D printers exist. They are pricey. They are intricate to run safely. Taking care of fine steel powder needs treatment. It can be dangerous. The printing process needs precise control. The post-processing requirements major tools and abilities. Grinding and sharpening metal properly is tough. Industrial configurations prevail genuine outcomes. Enthusiast printing typically implies plastic.

Q3: Would a 3D printed metal blade be discovered by safety and security? .

A3: Definitely. Metal detectors discover steel. A steel knife is steel. It matters not how it was made. X-ray scanners see the shape. Safety tries to find blade-like objects. A 3D published metal blade activates alarm systems. It uses no stealth benefit over a traditional blade at checkpoints.

Q4: Is it lawful to make one? .

A4: Regulations differ greatly. In several areas, owning or making knives is legal. Limitations often focus on blade size, type, or lugging in public. Making a blade itself isn’t generally unlawful. Using it as a weapon is prohibited. The “3D published” element adds little legally. It’s the blade itself and its desired use that matters. Constantly examine your regional laws.

Q5: Are they sharper or far better than store-bought blades? .

(can a 3d printed metal knife be a weapon)

A5: Not necessarily. Efficiency relies on the steel top quality, the warm treatment, the work, and the sharpening. A reliable 3D printed knife can be outstanding. An inadequately made one will be bad. Traditional blades benefit from centuries of improvement. Mass-produced knives supply consistent high quality. A printed knife’s side depends completely on the skill of the person finishing it. The printing simply creates the harsh form. The magic occurs in the grinding and sharpening.