Discover a professional 3D printing powder supplier

From Scrap to Superb: Just How 3D Steel Printing Slashes Waste .

(how does 3d metal printing reduce waste)

We talk a lot regarding making things far better, much faster, less costly. But what regarding cleaner? Traditional metal manufacturing typically leaves mountains of waste behind. Chips fly, portions obtain removed, important product winds up in the scrap bin. It injures the world and the pocketbook. Get in 3D steel printing, a technology transforming this waste story upside-down. It develops objects layer by layer, using just the material needed. Seems easy? The influence is big. This isn’t simply a brand-new way to make things; it’s a smarter, leaner, greener change for metal components.

Key Item Keyword: 3D Metal Printing.

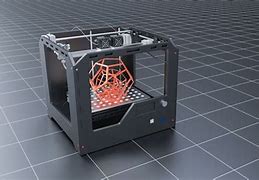

1. What is 3D Metal Printing? .

Think about building with steel, but rather than cutting or forming a huge block, you start from absolutely nothing. 3D metal printing, additionally called metal additive production (AM), develops components one exceptionally great layer each time. It utilizes digital plans, like a super-detailed computer illustration of the object. Effective energy sources, normally lasers or electron light beams, melt or fuse small particles of steel powder together, specifically where the style says to. Layer after layer gets included, slowly expanding the last component right out of the powder bed. It’s basically various. Typical approaches are subtractive: you start with excessive material and eliminate what you do not need. 3D steel printing is additive: you only placed material exactly where it belongs. This core distinction is the key to its waste-cutting power.

2. Why Does Waste Matter in Steel Production? .

Metal isn’t inexpensive. It takes enormous power to extract ore, improve it, and turn it into functional supply like blocks, bars, or sheets. When conventional machining sculpts a complicated component from a strong block, sometimes 90% or even more of that expensive starting product gets developed into chips or swarf. This scrap steel usually gets recycled, but reusing itself makes use of significant energy. Moving hefty scrap adds more price and emissions. There’s likewise the price of dealing with and saving this waste product safely. Past the material itself, lost power powers the cutting devices getting rid of all that excess steel. Coolants and lubricating substances utilized in machining end up being contaminated waste streams needing therapy. All this waste adds up quickly. It blows up manufacturing prices, drains sources, and burdens the setting. Locating means to utilize less product from the beginning is critical.

3. How Does 3D Metal Printing Reduce Waste? .

The magic of 3D metal printing depends on its precision and its additive nature. Right here’s how it slashes waste:.

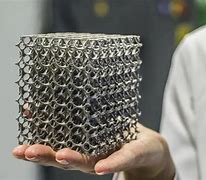

Just What You Need: The most significant win. The printer deposits or fuses material only where the style specifies. Picture making an intricate lattice structure inside a component. Conventional methods would certainly require to device away a strong block, leaving tons of scrap. 3D printing builds simply the latticework hairs, using very little product. Less starting powder equates to much less possible waste.

Style Freedom = Much Less Waste: Conventional manufacturing limitations layouts. Facility shapes, inner channels, or hollow structures are typically difficult or very inefficient to maker. 3D printing grows on complexity. It enables engineers to develop components maximized for feature, not simply manufacturability. This commonly indicates making use of far less worldly overall without sacrificing toughness. Light-weight parts imply much less material used per item.

Much Less Machining Later: While some 3D printed components need final finishing, the quantity of product eliminated is typically small contrasted to starting from a solid block. The part is currently near its last shape. This dramatically reduces the quantity of steel chips generated in post-processing.

Powder Reuse: Unused metal powder surrounding the published component in the build chamber isn’t automatically trash. Much of this powder can be meticulously sieved, tested, and blended with fresh powder for the next print task. This substantially lowers raw material consumption contrasted to approaches where chips are the primary scrap. Great powder administration is key below.

Fewer Stopped Working Castings: For intricate metal components made through casting (pouring liquified steel into a mold and mildew), the mold-making procedure itself can be wasteful. Patterns are usually destroyed during mold and mildew production. 3D printing can make mold and mildews directly, and even publish the final component itself, avoiding the mold stage and its linked material waste and possibility for faulty castings.

4. Applications Showcasing Waste Reduction .

The proof remains in real-world usage. 3D metal printing is making a tangible distinction:.

Aerospace: Weight is critical. Publishing lightweight, solid titanium or nickel alloy components with complex inner structures saves massive quantities of pricey material. Boeing reports some components attaining 90% less waste compared to machining. Gas effectiveness gains additionally follow from lighter parts.

Medical Implants: Customized hip or knee implants tailored completely to a patient’s composition are an archetype. Conventional techniques entail machining generic forms from big blocks, wasting most of the product. 3D printing develops the specific custom shape, decreasing waste and improving patient end results.

Tooling & Manufacturing Aids: Jigs, fixtures, and specialized tools frequently have intricate geometries. Printing them on-demand usages much less worldly than machining them from strong stock. It’s faster also. Broken devices can often be fixed by including material only where needed.

Spare Components: Preserving legacy machinery is difficult when parts are obsolete. As opposed to maintaining significant stocks or machining one-off substitutes (wasteful for single things), firms can print the specific part required, on-demand. This eliminates waste from overflow and warehousing.

High-Performance Automotive: Formula 1 and high-end cars and truck makers make use of 3D printing for complicated engine parts, light-weight brackets, and cooling down systems. The capacity to settle several parts right into one published device reduces setting up requirements and gets rid of waste from machining numerous parts.

5. Frequently Asked Questions Regarding 3D Steel Printing and Waste .

Is the unused powder really reusable? Yes, a significant portion usually is. Careful handling, sieving to get rid of lumps, and evaluating its homes enable it to be blended back right into the printing procedure. Eventually, some powder degrades and requires responsible recycling, but reuse prices are high.

Does not the printing process make use of a great deal of power? It can, especially the lasers or electron light beams. Nonetheless, studies typically show that when you consider the power conserved by using much less basic material, avoiding energy-intensive main metal manufacturing for that scrap, and reducing machining power, the complete lifecycle energy for a part can be reduced with AM. Energy effectiveness in printers is likewise improving.

Is the product as strong as traditionally made steel? Definitely. When done properly with professional products and processes, 3D printed metal parts can meet or surpass the strength and performance of cast or machined matchings. They are completely thick steel.

Can it publish any steel? Several common metals are currently: titanium alloys, stainless-steels, nickel superalloys (like Inconel), light weight aluminum alloys, cobalt-chrome, and also rare-earth elements like gold. Research continues to expand the array.

Is it really cost-effective for minimizing waste? It depends. For easy, cumbersome components, typical methods may still be cheaper. But also for complex, high-value parts made from expensive products (like aerospace titanium), or for personalized one-offs, the enormous decrease in product waste and machining time makes 3D printing very economical. The waste cost savings straight struck the bottom line. The ecological cost financial savings are considerable as well.

What happens to the support frameworks? Components needing support during printing (to stop sagging) create some waste when those supports are removed. However, this waste is normally much less than subtractive machining scrap. Initiatives concentrate on creating parts needing marginal supports and making assistances simpler to remove and recycle.

(how does 3d metal printing reduce waste)

Is it absolutely “green”? It’s a significant action in the direction of greener production. Utilizing less virgin material, reducing machining waste and associated fluids, making it possible for light-weight layouts (saving fuel in transport), and allowing neighborhood production (decreasing shipping emissions) all contribute. It’s not zero-impact, yet a significant enhancement over lots of standard approaches.