Discover a professional 3D printing powder supplier

Unlock the Glimmer: Crafting Metal Precious Jewelry with 3D Printing Magic .

(how to 3d print metal jewelry)

Ever before stare at complex, premium metal precious jewelry and marvel, “How on earth was this made?” The response progressively includes an unusual tool: a 3D printer. Forget large makers spitting plastic toys. We’re discussing developing magnificent rings, necklaces, earrings, and bracelets from actual, rare-earth elements utilizing cutting-edge technology. This guide dives into the interesting globe of 3D print steel jewelry .

1. What Exactly is 3D Printing for Steel Jewelry? .

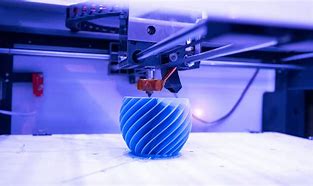

It seems like science fiction, making strong steel items layer by layer from an electronic file. For precious jewelry, it’s really real. Think about it as an ultra-precise, sophisticated means to construct complicated metal designs difficult with typical tools. It begins with a 3D design designed on a computer system. This design obtains sliced into exceptionally slim layers. Specialized printers after that develop the jewelry item, including product one tiny layer at a time. The bottom line: the final item is solid metal, prepared for ending up and use. Common steels utilized consist of sterling silver, gold (14k, 18k), bronze, brass, and even platinum. This isn’t plastic covered to resemble metal. This is the genuine offer, birthed from electronic desires.

2. Why Select 3D Printing for Your Metal Fashion Jewelry Creations? .

Why jump into 3D printing for fashion jewelry? The benefits are compelling. Initially, layout liberty explodes. Picture producing lace-like patterns, intricate interlocking components, hidden compartments, or organic shapes inspired by nature. These layouts are typically also complex or pricey to make by hand casting or machining. Second, it’s excellent for modification. Desire a ring with an one-of-a-kind finger print pattern, a pendant formed like an enjoyed one’s signature, or earrings matching a particular blossom? 3D printing makes personalized, distinctive items feasible without enormous arrangement costs. Third, it sustains fast prototyping. Developers can swiftly publish a model, test the fit and appearance, fine-tune the digital documents, and reprint much faster than standard methods permit. 4th, it minimizes material waste. The printer utilizes only the steel required for the item and its support frameworks, unlike sculpting away a solid block. Finally, it opens up doors for elaborate appearances and details difficult to accomplish by hand.

3. Exactly how Do You In Fact 3D Publish Steel Precious Jewelry? .

The procedure entails numerous key steps, each vital for a best last item:.

Design: All of it begins with a 3D version. Fashion jewelry developers use CAD (Computer-Aided Style) software application like RhinoGold, Matrix, or Blender to create their masterpiece digitally. Precision is vital here.

Submit Preparation: The completed 3D design requires to be converted into a layout the printer comprehends, typically STL. Specialized software program after that “slices” this design right into the hundreds or hundreds of slim horizontal layers the printer will certainly develop.

Printing: This is where the magic takes place. The two primary methods for fashion jewelry are:.

Steel Binder Jetting: A fine layer of steel powder (like stainless-steel, bronze, or rare-earth element blends) is spread. A print head jets a fluid binding representative onto the powder where the layer’s cross-section should be strong. This adhesives the powder particles with each other. Layer by layer, the bound “green” component is developed.

Wax Casting with 3D Printed Patterns: A high-resolution resin printer develops an incredibly in-depth wax version of the precious jewelry. This wax design is then made use of in the standard lost-wax casting procedure. Molten steel is put right into the mold and mildew created from the burnt-out wax, creating the last steel piece.

Post-Processing: Printed parts aren’t ready to use straight out of the device. Binder jetted “green” components are fragile. They go through sintering– a high-temperature heating system process that burns away the binder and integrates the steel fragments right into a solid, dense things. Components commonly reduce during sintering, so the initial style should compensate. After sintering, parts need considerable finishing: support removal, fining sand, brightening, rock setup, and plating if desired. Wax patterns need casting, followed by steel cleanup, completing, and sprucing up.

4. Awesome Applications: What Can You Make with 3D Printed Metal Precious Jewelry? .

The opportunities are nearly unlimited. Designers utilize this technology for:.

Complicated Geometric Patterns: Honeycombs, lattices, fractals, and architectural-inspired pieces shine.

Organic & Nature-Inspired Styles: Fragile flowers, swirling vines, intricate coral reefs structures, and textured surfaces resembling bark or stone come to be possible.

Lightweight Structures: Producing huge declaration pieces that are remarkably comfortable to put on as a result of hollow or latticework insides.

Interlocking & Moving Parts: Rings with rotating bands, pendants with relocating aspects, or brilliant holds.

Hyper-Personalization: Signet rings with 3D-scanned finger prints, necklaces shaped like customized soundwaves, or charms replicating miniature pictures.

Miniature Sculptures: Tiny, comprehensive porcelain figurines or imaginative kinds wearable as breastpins or pendants.

Customized Involvement Bands & Wedding Bands: Distinct designs tailored perfectly to the pair’s tale.

High-Fashion Statement Parts: Progressive designs pushing the borders of standard fashion jewelry making.

5. 3D Printed Metal Fashion Jewelry FAQs: Your Burning Concerns Answered .

Is it strong sufficient for daily wear? Yes. As soon as sintered and appropriately finished, pieces like rings and bracelets made from materials like stainless steel, titanium, or precious metals are durable. Sterling silver and gold pieces approach commonly cast products. Avoid extremely slim, unsupported delicate components on high-stress items like rings.

Does it look various from traditional fashion jewelry? Typically, the layout offers it away due to its intricacy. The metal itself, after polishing and finishing, looks identical to traditionally made pieces. Some unique surface textures from the printing/sintering procedure are sometimes left deliberately for visual effect.

Just how much does it cost? Expenses differ. Easy layouts in products like stainless-steel can be relatively economical. Facility styles in precious metals like gold or platinum carry significant material costs plus style, printing, sintering, and substantial hand-finishing labor. Customization likewise includes worth. It’s typically comparable to premium handmade or facility cast items.

Can I establish rocks in 3D printed precious jewelry? Absolutely. Stones can be established by hand after the metal item is ended up, much like traditional jewelry. Some advanced techniques even permit printing tooth cavities or settings straight right into the style.

Do I require my very own printer? Not generally. Lots of professional precious jewelry developers make use of specialized solution bureaus with industrial-grade steel printers. These bureaus take care of the printing, sintering, and often basic ending up. Hobbyist-level steel 3D printing is pricey and facility.

(how to 3d print metal jewelry)

What concerning surface coating? Right off the printer (especially binder jetting), the surface is harsh. Competent hand-finishing– fining sand, polishing, rolling, possibly layering– is necessary to achieve the smooth, shiny, or desired distinctive coating expected of great fashion jewelry. This step is labor-intensive but critical.