Discover a professional 3D printing powder supplier

Opening the Steel Magic: What Data Gas 3D Printing? .

(what type of data does 3d metal printing use)

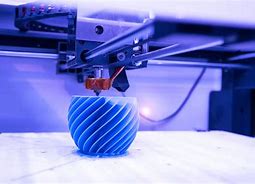

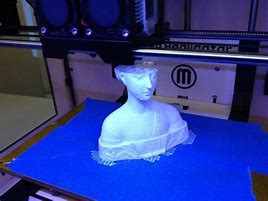

Photo a device crafting complicated steel components layer by layer. This isn’t sci-fi. This is 3D steel printing. However behind this modern technology exists a covert hero: information. What kind of data makes it tick? Let’s dive in.

1. What: 3D Steel Printing Data .

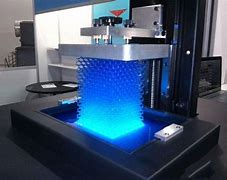

3D steel printing utilizes 3 core information types. Initially, geometric data. This is your component’s electronic plan. Think about it as a 3D map. It informs the printer every curve, angle, and opening. Second, product data. Metals like titanium or aluminum act in different ways. This information guides heat setups, laser power, and air conditioning prices. Third, procedure data. It tracks real-time variables. Layer density, temperature level, and print speed. These 3 information establishes collaborate. They turn an electronic desire right into a physical object.

2. Why: 3D Metal Printing Data Issues .

Negative information ways fell short prints. A small mistake in geometry? Your part might fracture. Incorrect temperature data? Metal might warp. Precision is non-negotiable. Data guarantees uniformity. It lets printers develop aerospace parts with zero flaws. It cuts waste. Conventional machining scratches away 80% of resources. 3D printing utilizes only what’s required. Data makes this performance feasible. It additionally accelerates development. Designers tweak designs digitally. They don’t squander weeks on physical models.

3. Just How: 3D Metal Printing Information Functions .

It begins with CAD software application. You design a part. The software slices it into ultra-thin layers. Each layer obtains converted into maker code. This code informs the printer where to move. It controls the laser melting metal powder. Sensors check every little thing. They examine if the laser is hot enough. They ensure powder layers are also. If something goes wrong, the system adjusts. Perhaps it reduces the print. Or raises the laser power. After printing, more data begins. Scanners contrast the component to the original design. They determine microns of variance.

4. Applications: 3D Steel Printing Data in Action .

Aerospace enjoys this. Jet engines make use of detailed steel parts. Data helps print lightweight wind turbine blades. They endure crazy warmth. Medical implants are another win. Doctors check a person’s bone. Data tailors a titanium hip. It fits completely. Automobile manufacturers use it too. They publish strong, light-weight brackets. Information enhances shapes human beings can not sketch. Even artists participate. Artists produce impossible steel swirls. Data transforms wild ideas right into fact.

5. FAQs: 3D Steel Printing Data Questions Answered .

Q: Is the information hard to manage?

A: Not today. Easy to use software does heavy lifting. You submit a CAD file. It handles slicing and code generation.

Q: Just how safe and secure is layout data?

A: Very. Encrypted data and blockchain tech safeguard blueprints. Unauthorized gain access to is difficult.

Q: Can data deal with printing mistakes mid-job?

A: Yes. Smart printers make use of AI. They spot defects like irregular melting. They self-correct quickly.

Q: Do little stores require pricey data tools?

A: No. Cloud services use economical gain access to. Pay per print task. No big upfront prices.

Q: What’s the most significant data obstacle?

A: Compatibility. Various devices review different layouts. But new standards are arising.

(what type of data does 3d metal printing use)

This data-driven change maintains expanding. Printers get smarter. Styles get wilder. Metal flexes to our will. All thanks to ones, nos, and human genius.