Discover a professional 3D printing powder supplier

Solid or Under Stress? The Genuine Toughness of Metal 3D Printing .

(how strong is metal 3d print)

So you have actually listened to the buzz about metal 3D printing. Possibly you saw an amazing video online. Possibly your employer stated it. The huge concern every person murmurs: “Is this printed steel stuff in fact strong?” It’s not nearly making complicated forms. People require components that last. Parts that manage stress and anxiety. Components that don’t break. Allow’s punctured the buzz and find out what steel 3D printing can actually deal with.

1. Exactly What is Steel 3D Printing Strength? .

Consider strength. It’s not just one point. Steel 3D printed components are examined similar to conventional steel parts. We look at numerous vital homes:.

Tensile Toughness: Pull a part up until it snaps. Just how much force did that take? That’s tensile toughness. Good information: several printed steels match or even defeat their cast counterparts here.

Return Toughness: Bend a paperclip a little. It springs back. Bend it as well much, it remains bent. The factor where long-term bending begins? That’s yield toughness. Important for parts under lots. Printed steels commonly execute well below also.

Exhaustion Stamina: Envision bending that paperclip backward and forward, consistently. The amount of times can it flex before it damages? That’s fatigue toughness. Components like engine parts encounter this regularly. Printed metals can be strong below, however surface area finish matters a great deal. Rough surface areas develop weak points.

Influence Durability: Hit it hard. Does it shatter or dent? Strength steps this energy absorption. Some published metals excel. Others might be a lot more breakable, relying on the material and process.

Thickness & Porosity: Tiny openings inside the metal? That’s porosity. It deteriorates the part. Excellent metal 3D printing goes for near-full thickness, suggesting virtually no holes. Think solid metal, not Swiss cheese.

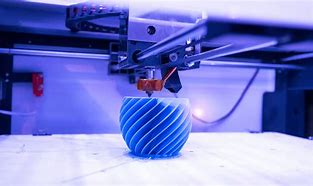

The strength isn’t magic. It comes from melting metal powder layer by layer with lasers or electron beams. Done right, the steel fuses entirely. The result is a solid, thick part. The toughness depends heavily on the metal powder utilized and exactly how meticulously the printing occurs.

2. Why Does Metal 3D Publish Strength Issue A Lot? .

This isn’t just academic interest. Toughness is the gatekeeper. It decides where printed steel components can be made use of. Weak components fall short. Fell short components set you back money. Stopped working parts can be dangerous. Take into consideration these points:.

Real-World Demands: Aerospace braces hold airplanes with each other. Clinical implants support bones. Automobile parts endure vibrations. These applications demand high stamina. They require dependability. Printing has to deliver.

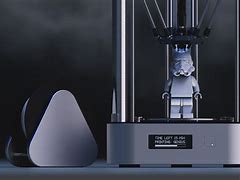

Beyond Prototypes: Early 3D printing was for designs. Now, it’s for end-use parts. Functional components. Components that work hard. Stamina is non-negotiable for these work.

Count on Element: Engineers beware. They need proof. Constant, trustworthy stamina information constructs confidence. It makes them choose printing over standard approaches.

Efficiency Boundaries: Knowing the toughness tells you the restrictions. How much weight can it hold? Just how much stress can it stand up to? The amount of cycles will it last? This specifies the part’s work.

Stamina issues due to the fact that it opens major applications. Without tried and tested strength, steel printing remains a leisure activity. With it, it ends up being a game-changer for industry.

3. Exactly how Do We Obtain Strong Steel 3D Printed Parts? .

Toughness does not happen by accident. It requires mindful control. Think of it like baking a best cake. You require the right active ingredients and the best actions. Right here’s how:.

Product Choice: Begin with the best metal powder. Common solid choices include Titanium (Ti-6Al-4V – super strong, light-weight), Stainless Steels (like 17-4 PH or 316L – difficult, corrosion-resistant), Light weight aluminum alloys (like AlSi10Mg – light-weight, respectable toughness), and Nickel-based superalloys (like Inconel 718 – unbelievably solid under warm). Each has its own toughness account.

Equipment Accuracy: The printer has to be calibrated completely. Laser power, scan speed, layer thickness– all these settings impact how the steel melts and fuses. Wrong settings indicate weak spots.

Warmth is Secret: Many published components need warm therapy. This is like tempering steel. It eliminates internal stresses accumulated during printing. It can likewise improve the steel’s microstructure. This step dramatically increases stamina and sturdiness.

Surface area Issues: Printed components often have a rough surface area. Tiny comes to a head and valleys act like stress concentrators. They are powerlessness. Machining or polishing the surface area smooths it out. This significantly improves exhaustion strength.

Style Smart: Printing allows incredible forms. However stamina depends on wise design. Prevent sharp corners. Usage gradual contours. Ensure the component’s interior structure (if utilizing lattices) is optimized for the lots. Publish alignment on the construct plate additionally affects strength instructions.

Obtaining strong parts requires knowledge. It’s a mix of scientific research, equipment know-how, and wise design.

4. Where Are Strong Metal 3D Prints Used Today? .

Neglect ornaments. Solid published steel is working hard today. Here are some genuine places it beams:.

Aerospace & Room: Weight is important. Toughness is crucial. Believe lightweight titanium brackets inside jet engines. Facility gas nozzles published as one item. Satellite components withstanding launch vibrations. Printing supplies complicated, light-weight, solid parts.

Medical Implants: Bone requirements strong support. Personalized titanium hip joints or spinal cages are printed to fit a person completely. They require unbelievable stamina and biocompatibility. Printing supplies both.

High-Performance Cars & Competing: Formula 1 groups press limitations. They utilize printed titanium components for suspension. Light weight aluminum parts for cooling down systems. They require stamina to handle severe pressures and reduce weight for speed.

Industrial Devices & Molds: Injection mold and mildews face warmth and pressure. Printed steel mold and mildews with intricate air conditioning channels inside last longer. They make better parts much faster. Cutting devices with printed carbide inserts stay sharper.

Energy & Oil/Gas: Extreme environments require tough materials. Printed nickel superalloy parts manage extreme heat in turbines. Corrosion-resistant stainless steel components operate in pipes and offshore rigs.

Robotics & Automation: Robotic arms need strong, light-weight joints. Printed aluminum or titanium parts give the needed strength without slowing down the robotic down.

These aren’t future desires. They are taking place today due to the fact that the stamina is proven and trustworthy.

5. Metal 3D Print Toughness: Your Top Questions Answered .

Let’s tackle those shedding questions head-on:.

Is published steel as solid as created metal? Frequently, yes! For tensile and yield strength, numerous printed steels match or beat cast metal. They can approach created strength. But tiredness toughness could require surface completing to match completely built components. It depends greatly on the particular steel and procedure.

What’s the best steel you can 3D print? Nickel-based superalloys like Inconel 718 are kings of high-temperature toughness. Titanium Ti-6Al-4V offers incredible strength-to-weight ratio. Tool steels are very hard and wear-resistant. “Strongest” depends upon the kind of toughness needed (tensile, heat, wear).

Does printing direction affect strength? Yes. Components can be a little more powerful in the instructions parallel to the print layers compared to vertical. Great design and heat therapy lessen this difference. It is very important to consider tons instructions when placing the component on the print bed.

Are there weak points? Potential weak spots include interior porosity (if printing isn’t optimal), harsh surfaces (injuring fatigue life), and layer lines (though blend is typically great). Mindful printing and post-processing solution these.

Is it more powerful than plastic printing? Definitely. No comparison. Also the toughest printed plastics fall much except the weakest published metals in terms of stamina, rigidity, and warmth resistance. Steel remains in a various organization.

(how strong is metal 3d print)

Just how expensive is it? Printing solid metal components sets you back more than plastic printing. Product prices are greater. Equipments are pricey. Post-processing includes expense. But for complicated, lightweight, high-performance parts, it can be more affordable total than typical manufacturing. You save money on tooling and product waste. You obtain the part quicker.