Discover a professional 3D printing powder supplier

Title: Steel 3D Printing on a Shoestring Spending Plan: Your Thrifty Guide .

(how to make metal 3d prints cheaply)

Key Item Keywords: cheap metal 3d prints.

1. What Exactly Are “Cheap Metal 3D Prints”? .

Let’s clear complication initially. Real steel 3D printing frequently involves expensive equipments thawing metal powder with lasers. We’re talking industrial equipment setting you back thousands of thousands. That’s not “cheap”. The affordable magic happens in a different way.

Think about it like this. As opposed to printing solid metal straight, we publish a composite product. This material is packed with little steel particles– stainless-steel, bronze, copper, even titanium– held together by an unique plastic binder. It resembles metal, feels heavy like metal, yet isn’t completely dense metal yet. That comes later. The published part is called a “eco-friendly state” part. It’s your metal prototype, shaped flawlessly, but needing extra actions to come to be the genuine bargain. This procedure is called Bound Metal Deposition (BMD) or Steel Fused Filament Fabrication (Steel FFF). It uses changed, much cheaper desktop computer printers comparable to routine plastic 3D printers. This is the core of obtaining “low-cost metal 3d prints”.

2. Why Go Low-cost? The Large Benefits of Budget Plan Steel Printing .

Expense is the evident star. Industrial metal 3D printing runs out reach for most people, small companies, and even numerous institutions. Desktop metal FFF systems and materials bring the starting cost down considerably. You might get a capable printer and starter filament for under $5000, in some cases much less. Compare that to the overpriced access price of powder bed blend makers.

Availability is significant. You don’t require an unique lab, industrial air flow, or a team of drivers. If you can run a routine 3D printer, you can find out to run one of these steel systems. It fits on a desk. This opens up steel prototyping and functional components to makers, designers, engineers, and teachers that never had an opportunity prior to.

Design liberty remains solid. Like other 3D printing, you can create complex forms, internal networks, and light-weight frameworks difficult with typical machining. Need a distinct bracket, a custom-made equipment, or an intricate art item? You make it, publish it in this metal-filled plastic, and process it.

Risk reduction issues. Examining a layout concept in actual metal made use of to be a big dedication. Now, you can iterate cheaply. Publish a version, examination it, tweak your style, print once again. All without damaging the bank or waiting weeks for outsourced machining. This quickens advancement enormously.

3. Just How It In fact Works: From Filament to Finished Steel .

The procedure has unique stages. Comprehending them is key to success and handling assumptions.

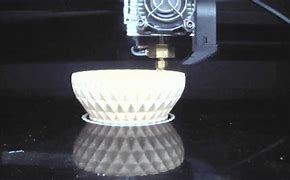

First, you publish the part. You utilize an unique filament. This filament is loaded with great metal powder (around 50-60% by volume) combined with a polymer binder. Printers made for this are normally durable, often enclosed, and have actually a set steel nozzle to manage the rough filament. Setups are vital– layer elevation, rates, temperatures– to stay clear of issues like cracking or contorting throughout printing. Perseverance is required; these prints are slower than normal plastic ones.

Next comes debinding. The newly printed “environment-friendly” part is mostly plastic holding metal with each other. We need to get rid of the majority of that plastic binder. This is usually done by soaking the part in an unique solvent bath for numerous hours, sometimes days. The solvent dissolves and washes away the binder, leaving the steel bits loosely held together by a percentage of leftover binder. The part is now really breakable and called “brown”.

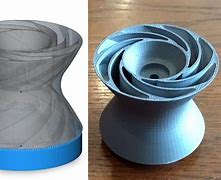

After that comes sintering. This is the magic action where it ends up being steel. The brownish part is put in a high-temperature heating system, typically under an unique atmosphere (like argon or hydrogen) to avoid oxidation. The heating system gradually increases to temperature levels near the steel’s melting point (yet simply listed below it). This severe heat makes the metal bits fuse with each other, densifying the component. The staying little bit of binder burns away. The component diminishes dramatically during sintering– typically 15-20% linearly. You must account for this shrinkage in your initial style! After cooling down, voila, you have a strong steel component.

4. Trendy Applications: What Can You Really Perform With Affordable Metal Prints? .

The opportunities are amazing, particularly for small-scale or bespoke products.

Prototyping reigns supreme. Designers and item developers can currently hold practical metal models in days, not weeks. Test fit, type, and even some feature prior to committing to costly manufacturing tooling. Assume engine parts, personalized tooling jigs, or architectural equipment mockups.

Customized Devices & Fixtures are best. Required a specialized wrench, a distinct positioning scale, or a long lasting jig for your workshop? Publish it in steel. It’s cost-efficient for one-offs and little sets. Much cheaper than CNC machining a solitary item.

Art, Fashion jewelry & Collectibles radiate. Artists create intricate steel sculptures difficult to carve or cast financially. Jewelers make distinct rings, pendants, and cufflinks in bronze, stainless, or copper. Enthusiasts might duplicate rare mechanical components or develop display screen pieces. The layout flexibility is a massive plus right here.

Substitute Components conserve the day. Broken an unusual classic car component? Required a certain brace for obsolete equipment? If you can model it, you can possibly publish and sinter a substitute in an appropriate metal. This is superb for remediation tasks or keeping old devices running.

Educational Versions are vital. Institutions and universities can now let pupils layout and hold real steel parts. Comprehending gears, systems, or architectural elements comes to be tangible. It brings advanced production ideas into the classroom cost effectively.

5. Frequently asked questions: Your Burning Questions Concerning Cheap Metal 3D Printing Addressed .

Q1: Just how solid are these sintered parts? Stamina depends greatly on the metal powder used, the sintering quality, and the part layout. They typically won’t match forged or wrought metal. They can be comparable to cast steel. Think useful prototypes, art pieces, light-duty devices. Not crucial aerospace parts. Thickness generally gets to 96-99% of strong metal.

Q2: Is the shrinking foreseeable? Yes, yet you must create for it. Filament makers give certain shrinkage elements (e.g., 17.5% on the X/Y axis, 20% on Z). You scale your 3D model up by this aspect before printing. Excellent slicing software application often has built-in settlement devices for specific products.

Q3: What metals can I utilize affordably? The most usual and economical desktop filaments are 17-4 PH Stainless Steel and different Bronzes (like CuSn10). Copper is available yet harder. Device steels and specialty steels like titanium exist however are considerably more costly per kilogram.

Q4: Do I truly require that unique furnace? Definitely. A routine ceramic kiln will not suffice. You require a high-temperature sintering heater (getting to 1300 ° C to 1400 ° C +) capable of specific temperature control and often a regulated atmosphere (vacuum or specific gas). This heating system is typically one of the most pricey component of the setup after the printer itself. Some solutions use sintering just.

(how to make metal 3d prints cheaply)

Q5: Why did my part warp or fracture? This prevails. Causes include: printing too rapid or also hot/cold, not enough assistance structures throughout printing, unequal wall thicknesses triggering unequal shrinking throughout sintering, or too fast heating/cooling in the furnace. Dialing in print setups and following sintering profiles carefully is crucial. It takes method. Support elimination before sintering is also important.