Discover a professional 3D printing powder supplier

Can 3D Printed Steel Actually Stand Up? Checking the Strength Within .

(How strong are 3d Printed Metal Parts Integrity)

We listen to a whole lot about 3D printing metal components. It seems futuristic, remarkable. Yet a big concern turns up: How solid are these 3D published metal components? Can they really manage laborious? Can they match, or even beat, metal components made the old method? Let’s dive deep right into the stability of these printed wonders. Forget the buzz. We’re taking a look at the real offer, the steel digestive tracts holding all of it with each other.

1. What Exactly is “Integrity” in 3D Printed Metal Components? .

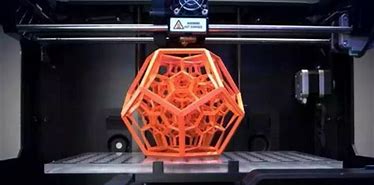

Think of “integrity” here. It suggests the part is strong through and through. It means strength, dependability, toughness. It means the part won’t split, flex, or break when pressed hard. For 3D published metal, this isn’t basic. The process constructs things layer by layer, melting fine metal powder with lasers or electron beams. Each layer bonds to the one below. Just how well those layers stick, just how dense the steel is within, and if there are covert weak spots– these decide the component’s stability. It’s about the entire item being continually strong, not just the surface area looking excellent. Visualize a brick wall surface. Stability means every block is solid, and the mortar in between them is rock solid. Weak bricks or brittle mortar mean the wall fails. It coincides for printed steel.

2. Why Does Metal Part Stability Matter A Lot? .

This isn’t just a designer’s challenge. It matters because genuine points depend on it. A weak part in a jet engine? Catastrophe. A falling short brace in a medical dental implant? Disaster. A damaged gear in a manufacturing facility robot? Costly downtime. Honesty chooses if a printed component is risk-free. It decides if it lasts long enough to be helpful. It determines if firms save cash making use of 3D printing or waste it on failures. If the honesty is inadequate, the part may look perfect but collapse under anxiety. Think of a bike structure. You trust it will not break when you hit a bump. That trust fund originates from recognizing the metal has high stability. For important usages– aerospace, medical devices, power generation– first-class stability isn’t optional. It’s the only thing that matters. Individuals’s lives and large money get on the line.

3. Exactly how Do We Achieve High Honesty in Printed Steel? .

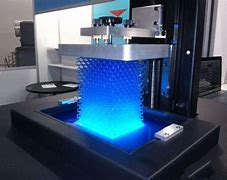

Obtaining solid, trusted components isn’t magic. It takes cautious control. Initially, the metal powder have to be very pure and the ideal dimension. Unclean or irregular powder suggests weak spots. Next off, the printing machine should be exceptionally specific. The laser or electron beam have to thaw the powder completely every single time. The temperature level should be perfect, layer after layer. Too warm? The steel obtains unusual crystals. Also cool? Layers do not bond well. The device’s atmosphere matters too. Printing commonly occurs in a chamber loaded with argon or another inert gas. This quits oxygen from reacting with the warm metal and making it brittle. After printing, many parts require heat treatment. Think of it like cooking. This extra warm cycle assists relieve inner stress and anxieties and makes the steel framework more powerful and a lot more uniform. In some cases, parts likewise get pushed in a hot isostatic press (HIP). This squishes the steel under high warm and pressure, squeezing shut any small pores left within. It’s like straightening out the creases deep within the metal. Every step, from powder to post-processing, is a web link in the chain of honesty.

4. Where Are High-Integrity Printed Steel Parts Used Today? .

The areas demanding leading stamina are adopting this technology quickly. Aerospace is a massive player. Assume jet engine gas nozzles, lighter-than-ever generator blades, and complex satellite elements. Why? Printing lets them make forms impossible with machining, reducing weight without cutting stamina. Lighter planes burn less fuel. Every gram counts when you’re flying. Clinical implants are an additional crucial area. Customized hip substitutes, knee joints, or spine cages can be published to fit a person flawlessly. The steel utilized, like titanium, bonds well with bone. High integrity makes sure these implants last decades inside the body. The energy sector utilizes them also. Tough components for oil and gas exploration, complex components for next-gen atomic power plants. Also high-performance vehicles and competing bikes utilize published metal parts. Groups print lightweight, super-strong suspension arms or transmission components. Customized tooling for manufacturing facilities is another large use. Rather than waiting weeks for a machined mold, a factory can publish a super-hard, long lasting tool in days. The common string? These applications require steel components that are strong, reliable, and commonly intricate. They can’t manage failure.

5. FAQs: Breaking Myths Regarding Printed Steel Toughness .

Individuals have concerns. Allow’s take on the big ones head-on.

Are published metal parts weak than built components? Sometimes yes, often no. It depends completely on the steel, the printer, the setups, and the post-processing. With leading devices and careful work, printed components can match and even go beyond the stamina of cast components. They may approach created strength in certain instructions. Yet creating is still king for utmost, uniform sturdiness in basic forms. Publishing success for complicated designs.

Is the strength the exact same in all directions? This is a key point. Typically, published components are slightly stronger in the direction the layers were developed (like stacking blocks). Perpendicular to the layers could be a little bit weak. This is called anisotropy. Good printing and HIP therapy minimize this difference significantly. It’s improving all the time.

Do published parts break much easier? Not if made appropriately. A well-printed, appropriately refined steel part has high stability. It will not just break. Like any kind of steel part, it can stop working if overwhelmed or improperly designed. But the printing itself isn’t an automated weakness.

What about fractures or openings inside? This is a real issue. Tiny pores or insufficient fusion in between layers can take place. This is why post-processing like HIP is so vital for crucial components. It squashes those pores shut. Excellent printing practices also minimize these flaws from the start. Inspection using X-rays or ultrasound locates any hidden flaws before the part goes into solution.

(How strong are 3d Printed Metal Parts Integrity)

Can I rely on a published component for something vital? Absolutely. But you need to rely on the source. Trusted producers utilize certified products, calibrated equipments, strict quality assurance, and comprehensive testing (like tensile examinations and fatigue tests). They confirm the integrity prior to the component ships. For non-critical usages, less complex published parts are great. For life-or-death applications, only collaborate with tested experts.