Discover a professional 3D printing powder supplier

Title: Metal Magic: Why We’re Printing Rockets, Robots, and Replacement Bones

(what is the purpose of 3d metal printing)

1. What Exactly Is 3D Metal Printing?

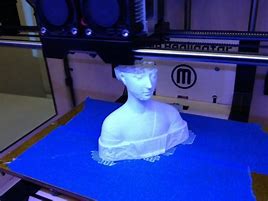

Forget paper and ink. 3D metal printing builds real, solid metal objects layer by layer. Think of a very precise, high-tech metal glue gun. It uses lasers, electron beams, or even metal powder and a binding agent. The machine reads a digital design file. It adds thin layers of metal powder or wire. It melts the material exactly where needed. Layer by layer, a solid metal part grows. This process has fancy names like Additive Manufacturing (AM) or Direct Metal Laser Sintering (DMLS). But the core idea is simple: building complex metal shapes directly from a computer model. No giant molds. No cutting away tons of metal. Just precise, layer-by-layer creation. It turns digital dreams into tangible metal reality.

2. Why Bother Printing Metal? The Big Advantages

Traditional metalworking methods work well. So why print metal? The reasons are powerful. First, design freedom is huge. Imagine parts with complex internal channels for cooling. Think of super lightweight structures with internal lattices. These shapes are often impossible with milling or casting. Printing makes them easy. Second, it reduces waste dramatically. Machining often cuts away up to 90% of a metal block. Printing uses only the metal needed for the part itself. This saves expensive materials like titanium. Third, speed matters. Creating a complex metal prototype can take weeks with old methods. Printing might take hours or days. Fourth, customization shines. Printing a unique medical implant for one patient is as easy as printing ten identical parts. Finally, it enables part consolidation. Instead of welding or bolting many pieces together, you print one single, stronger, lighter component. These benefits change how we make things.

3. How Does This Metal Printing Wizardry Actually Work?

Several methods exist, but two dominate. The first is Powder Bed Fusion. A thin layer of fine metal powder spreads across a build platform. A powerful laser or electron beam scans the powder. It melts the powder exactly where the part design dictates. The platform lowers slightly. Another layer of powder spreads. The laser melts again, fusing the new layer to the one below. This repeats thousands of times until the part is complete. Surrounded by unsintered powder, the part needs careful removal and cleaning. The second common method is Directed Energy Deposition. Here, metal powder or wire is fed directly into a focused heat source (like a laser or electron beam) near the build surface. The heat melts the material as it’s deposited, building up the part layer by layer. This is great for adding metal to existing parts or repairing components. Both methods happen inside sealed chambers, often filled with inert gas to prevent oxidation. After printing, parts usually need heat treatment and machining to achieve final tolerances and surface finish.

4. Real-World Applications: Where 3D Metal Printing Shines

This isn’t science fiction anymore. 3D metal printing solves real problems right now. The aerospace industry loves it. Printing complex, lightweight fuel nozzles or turbine blades makes rockets and jets more efficient. Boeing and Airbus use thousands of printed parts. Medical implants are another success story. Surgeons print custom hip replacements, spinal cages, or cranial plates perfectly matching a patient’s anatomy. This improves fit and healing. The automotive sector uses it for high-performance racing parts, custom tooling, and prototyping new engine designs faster. Tool and die makers benefit too. Printing conformal cooling channels inside molds drastically cuts production cycle times. Energy companies print unique parts for gas turbines and oil drilling equipment. Even art and jewelry designers use metal printing for intricate, impossible-to-cast creations. The applications keep expanding as the technology improves.

5. 3D Metal Printing FAQs: Your Burning Questions Answered

Is it strong? Absolutely. Printed metal parts can be as strong, or even stronger, than traditionally made parts. Proper printing and post-processing ensure high density and material integrity. They meet demanding aerospace standards.

What metals can be printed? Many! Common ones include titanium (strong, lightweight, biocompatible), stainless steel (versatile, corrosion-resistant), aluminum (lightweight), nickel alloys (heat resistant), cobalt-chrome (hard, wear-resistant), and even precious metals like gold.

Is it expensive? Yes, upfront costs are high. The printers themselves cost a lot. Metal powders are expensive. Post-processing adds cost. But for complex parts, low-volume production, or critical applications, the total cost (considering design freedom, speed, waste reduction) can be very competitive. Costs are falling steadily.

Are there size limits? Yes. Build chambers limit the maximum part size. However, printers are getting larger. Big industrial machines can print parts over a meter in length. For huge structures, parts are printed in sections and assembled.

What about surface finish? Printed parts often have a rougher surface than machined parts. Think fine sand texture. Post-processing like machining, polishing, or bead blasting is usually needed for a smooth finish. This is improving with better printing techniques.

(what is the purpose of 3d metal printing)

Can it replace traditional manufacturing? Not entirely, and not soon. It excels at complex, low-to-medium volume parts, prototypes, and custom items. Mass-producing simple nuts and bolts? Traditional methods like stamping or casting are still far cheaper and faster. It’s a powerful complementary tool, not a total replacement.