Discover a professional 3D printing powder supplier

Hunting for Metal Magic: Your Guide to Acquiring Steel 3D Prints .

(where to buy metal 3d prints)

Discovering where to buy metal 3D prints feels like unlocking a secret workshop. This modern technology builds facility, strong steel components directly from digital layouts. It opens up doors for creators, designers, musicians, and services. You need dependable sources. This overview puncture the complication. We reveal you precisely where to locate these incredible metal developments and just how to select the best choice.

Key Product Search Phrase: Metal 3D Prints.

1. What Exactly Are Steel 3D Prints? .

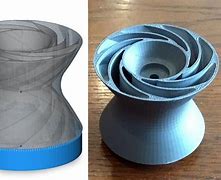

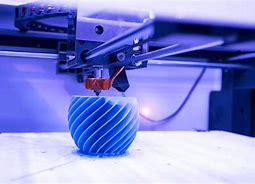

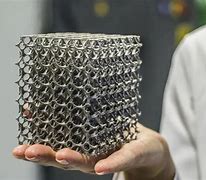

Steel 3D prints are strong metal things made by machines. These devices develop components layer by layer. They use effective lasers or electron light beams. The beam of lights thaw great metal powder, fusing it specifically. This differs significantly from reducing metal away (subtractive manufacturing). Consider it like building a sandcastle grain by grain, but with metal and lasers. Usual metals made use of consist of stainless steel, titanium, light weight aluminum, and also unique alloys like Inconel. The process creates components impossible to make with conventional devices. Think elaborate internal networks, complex latticeworks, or natural shapes. The result is an actual steel part, all set for requiring use. It could require some final polishing or warm therapy. The core magic is building complicated metal forms straight.

2. Why Choose Metal 3D Printing? Why Not Typical Methods? .

Steel 3D printing resolves troubles old methods can not handle. Its biggest stamina is geometric freedom. You can create forms machining merely can not get to. Interior tooth cavities, damages, honeycomb structures– no problem. This leads to lighter, stronger parts. Assume aerospace braces using much less fuel. It enables rapid prototyping in real metal. Test practical components fast, not simply plastic models. Need an unique part, simply one? Traditional tooling costs a lot of money. Steel 3D printing is ideal for low-volume manufacturing or custom-made one-offs. It usually utilizes product much more effectively, producing much less waste. It allows part combination. Incorporate numerous elements right into one printed item. This reduces setting up points and potential failure areas. For intricate designs or small sets, metal 3D printing is typically quicker and a lot more cost-efficient. It opens technology.

3. How Do You Really Acquire Metal 3D Prints? Trick Actions. .

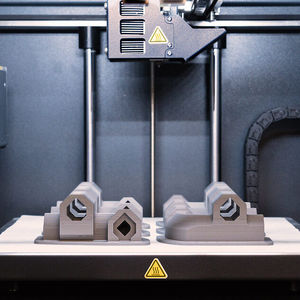

Getting steel 3D prints isn’t like purchasing a basic component. You typically require a 3D version data (like.STL or.STEP). Initially, recognize your precise need. What product? What toughness? What surface coating? The number of copies? Next off, discover a provider. Numerous kinds exist. Online production systems (like Xometry, Protolabs, Hubs) supply instant quotes. They attach you to numerous vetted factory. Committed 3D printing solution bureaus specialize just in additive manufacturing. They supply deep knowledge. Some device makers also provide printing services. Inspect their capacities match your product and size needs. Get quotes from a few locations. Compare not simply rate, yet lead times, product qualifications, and post-processing options. Inquire about style standards. They can assist optimize your component for printing, conserving money. Lastly, post your documents, accept the quote, and await your metal magic to arrive.

4. Outstanding Applications: Where Metal 3D Prints Shine. .

Metal 3D prints are changing sectors. Aerospace enjoys them. They make lightweight, super-strong parts for jets and rockets. Turbine blades, gas nozzles, structural brackets benefit greatly. Medical implants are an ideal fit. Patient-specific hip replacements or spine cages use biocompatible titanium. Dental crowns and bridges are made in this manner also. The auto industry utilizes them for customized racing components, lightweight braces, and complicated warm exchangers. Tooling gets an increase. Conformal air conditioning channels inside mold and mildews cool plastic quicker, speeding up manufacturing. Power sectors use them for tough components in turbines and exploration devices. Artists and jewelry experts create complex, impossible steel sculptures and bespoke items. Even consumer goods see custom premium bike parts or one-of-a-kind watch components. Wherever facility, strong, lightweight, or custom-made steel is needed, 3D printing steps in.

5. Steel 3D Print Buying FAQs: Your Questions Addressed. .

(where to buy metal 3d prints)

Individuals usually ask similar features of purchasing steel prints. How much do they set you back? Rates vary a whole lot. Intricacy, dimension, product, and coating issue. A tiny stainless steel bracket might set you back $100. A large titanium aerospace part can set you back thousands. Obtain quotes. How solid are they? Correctly printed and refined components can match or exceed actors steel stamina. Some even method forged toughness. Certification is vital for crucial components. How much time does it take? Preparations vary from a few days for easy parts to weeks for complicated, accredited things. Thrill solutions exist. Can I obtain any metal? Not all metals publish quickly. Usual ones are titanium, aluminum, stainless steel, Inconel, cobalt chrome. Ask your carrier. What surface coating can I expect? As-printed parts are usually harsh. Options include sandblasting, machining, brightening, and plating. Review this upfront. How accurate are they? Modern systems are very specific. Anticipate tolerances around +/- 0.1 mm to +/- 0.3 mm depending upon the procedure and part dimension. Style for the innovation. Do I possess the design? Yes, you keep copyright unless agreed otherwise. Respectable solutions protect your information.