Discover a professional 3D printing powder supplier

Is 3D Printing Steel an Energy Guzzler? Unloading the Power Behind the Refine .

(is 3d printing metal energy)

Steel 3D printing seems like pure sci-fi magic. Picture a machine structure facility rocket engines or personalized clinical implants layer by layer, directly from digital documents. It’s amazing. Yet this remarkable modern technology does not operate on fairy dirt. It needs real power, typically lots of it. So, the huge concern pops up: Is 3D printing steel a huge energy drainpipe? Allow’s dive into the volts, the warm, and the actual story behind the power impact of structure metal parts with lasers and powder.

Key Item Key Words: 3D Printing Steel.

1. What Exactly is 3D Printing Steel? .

Think of it like very exact, super-hot welding, however regulated by a computer. As opposed to sculpting away product from a large block (subtractive manufacturing), 3D printing steel develops things up, including product only where it’s required (additive manufacturing). One of the most typical method for steels is called Powder Bed Blend. Below’s the basic idea:.

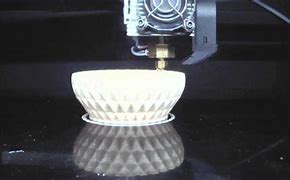

A slim layer of great metal powder, better than flour, obtains spread across a construct platform. A powerful laser beam of light or electron light beam then zaps particular places on that powder layer. The extreme warmth thaws the steel bits with each other, fusing them solid according to the digital design. The system decreases a little. An additional layer of powder is spread out on top. The laser thaws the new layer, bonding it to the one listed below. This repeats, layer by layer, till the entire metal part is developed inside a cake of extra powder. After it cools, you dig out the finished part and clean off the excess powder. Other approaches exist, like blowing metal powder via a nozzle thawed by a laser (Directed Energy Deposition), however Powder Bed Fusion is the heavyweight champion for complex, top quality metal parts right now.

2. Why Does 3D Printing Metal Usage A Lot Power? .

The power appetite originates from numerous starving sources interacting. Initially, the warm. Thawing metal needs severe temperature levels. We’re speaking countless degrees Celsius. The lasers or electron beam of lights generating this warm are extremely effective, commonly numerous kilowatts. They run continuously during the develop, which can take hours and even days for big components. That’s a great deal of power. Second, the environment. The whole melting procedure happens inside a secured chamber loaded with inert gas (like argon or nitrogen). This gas stops the hot, reactive molten steel from oxidizing or blowing up. Pumping, detoxifying, and keeping this safety atmosphere constantly eats power. Third, preheating. In some cases the entire construct platform and the powder bed itself require preheating to thousands of levels. This lowers thermal stress and anxiety in the component during printing. Getting that big mass of steel warm and keeping it warm takes significant power. 4th, support systems. Powerful computer systems manage everything. Air pump could be required for electron light beam systems. Cooling down systems work hard to manage the warm generated. All these assistance functions add to the overall power bill. It’s the mix of high-power melting, environmental control, pre-heating, and complementary systems that makes it energy-intensive.

3. Just How Can We Make Metal 3D Printing More Power Reliable? .

The good news is that clever individuals are working hard to minimize the power hunger. Below’s just how:.

Better Lasers: Newer laser modern technologies are coming to be more effective. They provide the specific power required precisely where it’s needed, wasting less power as warmth.

Smarter Heating: Instead of warming the whole enormous construct chamber, systems are being developed to warmth just the location quickly around where the laser is thawing. This targeted home heating uses much less power.

Process Optimization: Software is getting smarter. It can find ways to develop components faster, decreasing the total machine run time. Less time running ways much less energy made use of general. Maximizing laser courses and support structures likewise aids.

Product Technologies: Some new steel powders are designed to melt at slightly reduced temperature levels. Also a tiny reduction in melting factor can conserve an obvious amount of energy.

Recycling Heat: Capturing the waste warmth created by the lasers and the melting procedure is a big opportunity. This caught warmth might possibly preheat brand-new powder or heat the build chamber, decreasing the requirement for fresh electrical home heating.

Scaling Up: As the innovation grows and extra machines are developed, economies of scale and competitors drive effectiveness enhancements. More efficient power materials and far better system combination normally follow.

4. Where is 3D Printing Steel Utilized Today? (And Does Power Issue?) .

Despite the energy concerns, 3D printing steel is revolutionizing a number of sectors because its benefits typically surpass the expenses:.

Aerospace: This is a significant user. Printing facility, light-weight parts like wind turbine blades, gas nozzles, and architectural brackets is best. These parts are often impossible to make generally. Weight cost savings directly convert to large fuel financial savings over an airplane’s life, potentially countering the printing power. Customized rocket engine parts are additionally common.

Medical: Producing custom-made, patient-specific implants (like titanium hip joints or head plates) is a game-changer. The perfect fit enhances client end results. Dental crowns and bridges are additionally increasingly printed. The high value of these bespoke things makes the energy expense much less important.

Automotive: High-performance and deluxe auto makers use it for lightweighting models, custom-made components, and complicated components like warm exchangers. Competing groups like it for quick model of maximized components. Power use is a variable, yet speed and performance typically come first here.

Tooling & Production: Printing conformal air conditioning networks straight inside shot mold and mildews dramatically enhances cooling effectiveness in plastic part production. This conserves considerable energy during the molding process itself. More powerful, longer-lasting custom-made jigs and components are additionally printed.

Power Market: Turbine components, warmth exchangers, and components for oil & gas removal benefit from the style flexibility and fast production abilities. Repairing high-value parts using directed energy deposition is also expanding.

In high-value, complicated, or customized applications, the one-of-a-kind benefits of metal 3D printing frequently validate its power usage. The focus is shifting towards maximizing the process and finding methods to reduce that impact.

5. Steel 3D Printing Power: Your Top Concerns Addressed .

Let’s tackle some common energy-related questions:.

Is it always more energy-intensive than typical manufacturing? Generally of course, for the component itself. But consider the entire lifecycle. If a published component is substantially lighter (like in aerospace), it saves fuel for many years. If it enables a more effective process (like conformal cooling mold and mildews), it conserves energy downstream. If it prevents massive material waste from machining, that’s a conserving too. The total energy image can be complex.

Just how much energy does it really utilize? It differs wildly. A little component may make use of 10s of kilowatt-hours (kWh). A big, complicated part taking days could use hundreds or even over a thousand kWh. Contrast that to thawing the exact same steel for casting, which could utilize less power for the melt however usually entails more actions and material waste.

Is it getting better? Yes, absolutely. Device makers are frequently boosting performance. Laser efficiency is up. Refine optimization software is much better. Recognition of energy usage is higher, driving development. It’s still energy-hungry, yet the fad is towards making use of much less per component printed.

Does the steel type issue for energy? Yes. Steels with really high melting factors (like tungsten) call for even more laser energy than those with reduced factors (like aluminum or titanium alloys). The powder characteristics additionally contribute.

(is 3d printing metal energy)

Are renewable energy sources a choice? Absolutely. Powering metal 3D printers with solar, wind, or other renewables directly resolves the carbon impact of the electricity made use of. This is a growing focus for lasting production.