Discover a professional 3D printing powder supplier

From Plastic to Prestige: Your Guide to Metal-Shine 3D Prints

(how to make a 3d print look like metal shining)

So you’ve printed something cool. But it looks like… well, plastic. You want that wow factor, that instant “Is that real metal?” reaction. Good news. Making your 3D print gleam like polished steel, shimmer like chrome, or glow like aged bronze isn’t just possible; it’s surprisingly doable. Forget the dull finish. Let’s unlock that metallic magic.

1. What is a Metal-Shine Finish for 3D Prints?

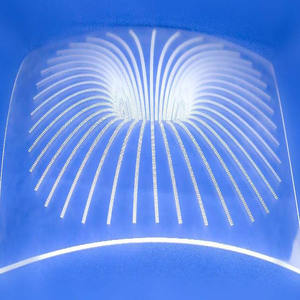

It’s exactly what it sounds like. Taking a standard plastic 3D print and transforming its surface so it visually mimics real metal. This isn’t just about color. Real metal reflects light in specific ways. It has depth, luster, and sometimes even texture. A true metal-shine finish captures these qualities. Think less “gray paint” and more “polished aluminum hood ornament.” The goal is deception – fooling the eye and sometimes even the fingertips. This finish hides the layer lines inherent in FDM printing. It smooths out the surface. It adds that characteristic metallic sheen and depth. The result? Your PLA, ABS, or resin creation looks like it was cast, forged, or machined from solid metal. It elevates the perceived value instantly.

2. Why Bother Making Your Print Look Metallic?

Plastic is great. It’s versatile and cheap. But sometimes, only metal has the right vibe. Maybe your cosplay prop needs authentic weight and look. Perhaps your architectural model demands realistic metal fixtures. Or your custom gadget enclosure craves a premium feel. Achieving a real metal part is often expensive. Machining costs soar. Casting requires molds. Metal 3D printing? That’s a whole other price bracket. Giving plastic a metal finish bridges this gap beautifully. It offers the visual impact and perceived quality of metal without the hefty cost or manufacturing complexity. It makes prototypes look like final products. It turns hobby projects into display-worthy pieces. It adds a layer of realism to models and miniatures. Basically, it makes your print look significantly more expensive and professional than it actually is. That’s a powerful upgrade.

3. How to Achieve That Coveted Metal Shine (Step-by-Step)

Getting that convincing shine requires prep work and the right technique. Here’s the core process:

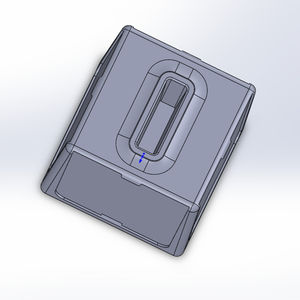

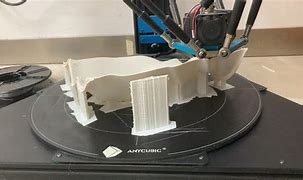

Prep is King: Start with the best print possible. Lower layer heights (like 0.1mm or less) mean less sanding later. Clean supports carefully. Remove strings and blobs. This foundation matters.

Smooth the Canvas: Sanding is non-negotiable. Start coarse (around 120-220 grit) to knock down major layer lines and defects. Progress through finer grits (400, 600, maybe 800 or 1000). Aim for a uniform, smooth surface. Wipe away dust constantly. For tricky details, use sanding sticks or foam pads. Filler primer helps massively. Spray several light coats, sanding smooth between coats. This fills tiny imperfections.

Prime for Perfection: Apply a high-quality primer. Gray is often best for metallic finishes as it provides a neutral base. Let it cure fully. Sand lightly with very fine grit (like 1000+) for a glass-smooth feel. Wipe clean.

Choose Your Metal Magic:

Metallic Paints: The most accessible route. Use high-quality spray paints specifically labeled “metallic,” “chrome,” or named after metals (like “Brilliant Silver,” “Oil-Rubbed Bronze”). Apply in multiple very light, even coats. Hold the can far enough away. Heavy coats look splotchy and ruin the effect. Let each coat flash off properly. Buffing some metallic paints lightly after curing can enhance shine.

Metal Plating (Electroplating/Electroless): This gives the most authentic metal look and feel. It involves coating the plastic part in a conductive layer (special paint or graphite powder). Then you immerse it in a plating solution (like nickel or copper) and run an electrical current (electroplating) or use a chemical bath (electroless plating). The metal ions bond to the surface. This requires more setup and chemicals but delivers stunning, durable results.

Metal Leaf/Foil: Applying ultra-thin sheets of real metal (like gold leaf or aluminum foil) using adhesive size. It’s labor-intensive but creates incredible, reflective surfaces. Great for small areas or accents.

Rub ‘n Buff & Pastes: Waxy metallic pastes applied with a finger or cloth. Rub them onto the primed surface, focusing on high points. Buff to a shine. Great for aging effects or highlighting details.

Seal the Deal (Sometimes): Clear coating metallic paint can protect it. But beware! Many clears dull the metallic sparkle. If you must clear coat, use a gloss clear specifically designed for metallics. Apply ultra-light mist coats first. Test on scrap. Plated finishes usually don’t need sealing.

4. Applications: Where Metal-Look Prints Shine

This technique isn’t just for show; it’s incredibly useful:

Cosplay & Props: Lightsabers, armor plates, robot parts, steampunk gadgets, weapon replicas. A metal finish sells the illusion instantly. It makes foam look like steel.

Scale Models & Miniatures: Realistic car bodies, aircraft fuselages, engine parts, architectural details like railings and vents. Tiny details pop with metallic luster.

Functional Prototypes: Presenting a design that needs to look like a final metal product for investor meetings or client reviews. It conveys quality and seriousness.

Custom Enclosures & Housings: Giving DIY electronics projects, Raspberry Pi cases, or speaker grills a premium, brushed aluminum or chrome look.

Jewelry & Wearables: Creating custom rings, pendants, bracelets, or belt buckles that look like precious metals without the precious price tag.

Art & Sculpture: Adding metallic accents or creating entire pieces with a bronze, copper, or silver aesthetic. The reflective quality adds depth.

Replacement Parts: Making non-structural knobs, dials, or trim pieces that match the metal finish of an existing product.

5. Metal Finish 3D Printing FAQs

Let’s tackle common questions:

Does it feel like metal? Painted finishes still feel like coated plastic. Plating feels much closer to actual metal – cold and hard to the touch. Rub ‘n Buff has a slightly waxy feel. Metal leaf is thin but feels like metal.

How durable is it? Metallic paints are reasonably durable for display pieces. Plating offers excellent durability and scratch resistance. Metal leaf is delicate. Avoid heavy abrasion on all finishes. Clear coating paint helps.

What filament works best? ABS is excellent due to its smoothness and chemical resistance (important for plating or smoothing). PLA is fine for painting, but can be brittle. Resin prints offer the smoothest starting point, ideal for high-gloss finishes. Avoid very flexible filaments.

Can I get different metal colors? Absolutely. Beyond silver/chrome, look for paints mimicking gold, copper, bronze, brass, gunmetal, rose gold, etc. Plating can also be done in different metals or patinated.

Is plating safe at home? Electroplating requires handling chemicals and electricity safely. Proper ventilation, gloves, and eye protection are essential. Electroless kits are generally safer but still require care. Research thoroughly before starting.

Why does my metallic paint look dull/grainy? Common causes: spraying too heavy a coat, holding the can too close, not shaking the can enough, poor surface prep (rough underneath), humidity during spraying, or using a low-quality paint. Light, even coats are key.

(how to make a 3d print look like metal shining)

Can I polish a painted finish? Some high-quality metallic paints can be lightly buffed with a very soft cloth after they are fully cured. Test first! Over-buffing removes the metallic flakes. Plated finishes polish beautifully like real metal.