Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

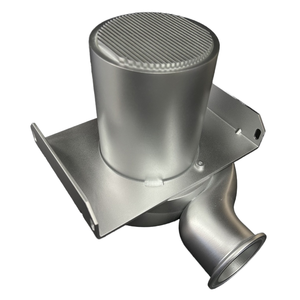

Overview of 3D Printing CNC Machining Services for Metal Plastic Products Rapid Prototyping Manufacturing Specializing Stainless Steel parts

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of 3D Printing CNC Machining Services for Metal Plastic Products Rapid Prototyping Manufacturing Specializing Stainless Steel parts

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(3D Printing CNC Machining Services for Metal Plastic Products Rapid Prototyping Manufacturing Specializing Stainless Steel parts)

Specification of 3D Printing CNC Machining Services for Metal Plastic Products Rapid Prototyping Manufacturing Specializing Stainless Steel parts

We offer top rate 3D printing CNC machining services for steel plastic items. Our focus is rapid prototyping production. We specialize in stainless steel components. You obtain fast accurate parts for testing layout verification.

Our 3D printing deals with numerous plastics. We use technologies like SLA SLS FDM. These develop complicated forms rapidly. Plastic models benefit kind fit checks. They are affordable early in advancement.

CNC machining supplies high accuracy metal plastic components. We use sophisticated mills lathes. This process suits practical prototypes requiring limited tolerances. It works well for end usage parts too. Product toughness surface coating are excellent.

Stainless-steel is our specialized. We machine qualities like 304 316. These withstand deterioration carry out well under stress. Stainless components are vital for clinical tools food handling equipment. They work in marine environments.

We provide both solutions under one roofing. This conserves you time control initiative. Pick 3D printing for speed facility geometries. Pick CNC machining for stamina precision metal components. We recommend the best method for your task.

Product selection is broad. Plastics include ABS nylon polycarbonate. Metals cover aluminum brass titanium stainless-steel. We source accredited products for consistent top quality.

Surface area completing choices are readily available. We provide bead blasting anodizing plating painting. Components look perform like end products. This is crucial for user screening discussions.

Our team comprehends making challenges. We help you move from idea to physical component quickly. We sustain start-ups large companies. Our objective is your job success.

(3D Printing CNC Machining Services for Metal Plastic Products Rapid Prototyping Manufacturing Specializing Stainless Steel parts)

Applications of 3D Printing CNC Machining Services for Metal Plastic Products Rapid Prototyping Manufacturing Specializing Stainless Steel parts

3D printing and CNC machining solutions create steel and plastic components quick. These methods are best for rapid prototyping. Designers examination ideas swiftly using genuine physical designs. This saves money and time early in product development. Both plastic and metal products function well. Stainless steel components are a key specialty. These services take care of intricate stainless steel shapes quickly. CNC machining cuts specific steel components from strong blocks. It provides exceptional stamina and smooth surfaces. 3D printing builds parts layer by layer directly from digital documents. It permits really intricate internal functions difficult with other methods. This is wonderful for detailed prototypes or custom tooling.

You get useful models fast. Examination components under genuine conditions prior to full manufacturing. Find design defects early. Make fast adjustments without huge delays. These services sustain little sets also. Need a few loads custom-made stainless-steel brackets? They can do that successfully. Stay clear of huge minimum orders typical elsewhere. Product choice matters. Plastics use adaptability and lower expense for early versions. Steels like stainless-steel supply toughness and toughness for demanding examinations. Stainless-steel withstands corrosion and deals with high stress and anxiety. It’s perfect for aerospace, clinical gadgets, and auto uses.

Relocating past prototypes is easy. The same machines and abilities make end-use production components. Preserve premium quality and accuracy for final products. This versatility covers the whole procedure. Beginning with a principle design. Refine the layout through numerous model variations. Then create tiny batches of the last stainless-steel component. Speed is a major advantage. Obtain parts in days, not weeks. React quickly to market changes or client comments. Reduce your time to market considerably. These solutions use a functional solution for steel and plastic requirements. They focus on rate, top quality, and convenience. Stainless-steel knowledge is a clear toughness.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of 3D Printing CNC Machining Services for Metal Plastic Products Rapid Prototyping Manufacturing Specializing Stainless Steel parts

Here are 5 common questions about our 3D printing and CNC machining services for metal and plastic rapid prototyping, especially stainless steel parts:

What materials can you use? We handle many metals and plastics. Metals include stainless steel, aluminum, brass, and titanium. Plastics cover ABS, nylon, polycarbonate, and others. Stainless steel is a specialty for parts needing strength and corrosion resistance.

How do I pick between 3D printing and CNC machining? Consider your part’s needs. 3D printing builds complex shapes layer by layer, good for intricate designs. CNC machining cuts material away, better for very strong, precise parts with tight tolerances. We help you decide based on your project.

What finish can I expect on my parts? Both methods give functional parts. CNC parts usually have a smoother surface right off the machine. 3D printed parts often show layer lines. We offer finishing options like sanding, polishing, or painting for both types. This improves appearance and feel.

How precise are your parts? Precision is crucial. CNC machining offers high accuracy, typically around ±0.005 inches or better. Metal 3D printing is also precise, generally within ±0.005 inches. Plastic 3D printing tolerances vary more by material and process. We discuss your specific tolerance needs upfront.

How fast is rapid prototyping? Speed is key. 3D printing is often faster for initial concept models, sometimes delivering parts in days. CNC machining might take longer for complex parts but provides production-ready results quickly. Metal 3D printing takes more time than plastic. We provide realistic timelines based on your design and chosen method.

(3D Printing CNC Machining Services for Metal Plastic Products Rapid Prototyping Manufacturing Specializing Stainless Steel parts)