Discover a professional 3D printing powder supplier

Restoring Your Sandy 3D Printed Metal Masterpieces: A Cleaning Overview .

(how to clean roughened 3d printed metallics)

That unbelievable metal element simply popped off your printer. It looks solid, it really feels heavy … however the surface area? It’s rough. Actually harsh. Like it just wrestled a sandpaper monster. Do not stress, that gritty texture is totally regular for lots of 3D published metal parts fresh off the maker. But transforming that rough monster right into a smooth, sleek, or flawlessly prepped piece is important. Let’s get your steel prints looking and feeling great.

1. What Are Roughened 3D Printed Metallics? .

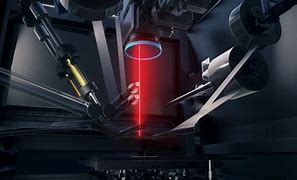

You recognize that satisfying sensation of holding a solid steel object? 3D printed metallics go for that. Unlike plastic prints, these components begin as fine steel powder– assume stainless-steel, titanium, aluminum alloys, even bronze. Special printers make use of lasers or binders to fuse this powder layer by layer into your design. The “roughed up” part comes right from the process. The unfused powder clinging to the surface, the tiny stair-step effect from layering, and the means the steel fragments sinter together produce a normally gritty, unequal structure. It’s not an imperfection; it’s the raw, unfinished state. This roughness impacts just how the component looks, really feels, and also exactly how well paint or other finishes stick later on. Recognizing this beginning factor is key to cleansing it right.

2. Why Bother Cleansing Roughened Metal Prints? .

Leaving that rough surface area unblemished isn’t typically an option. First, there’s leftover powder. It obtains all over– in crevices, holes, strings. This loose powder is untidy. It can jam moving components, interfere with electrical links, or merely rub off on everything. Second, the rough texture itself could not be what you require. Perhaps you desire a smooth bearing surface, a sleek decorative coating, or a clean surface area for painting. Third, that roughness can catch dust, oils, and wetness. Caught wetness can bring about rust, especially on materials like some steel alloys. Cleaning removes the powder particles and prepares the surface. You get a part that’s much safer to deal with, functions much better, looks specialist, and is ready for any more finishing actions you desire. It transforms your print from a prototype to a useful part.

3. Exactly How to Clean Roughened 3D Printed Metallics Properly .

Safety first! Use handwear covers and eye protection. Steel powder and dirt are serious. Begin straightforward. Usage pressed air. Burn out loosened powder from all surface areas, holes, and internal channels. Be extensive. Next off, tackle the surface area grit. Below are your main tools:.

Cleaning: Make use of tight nylon or metal brushes (inspect your steel kind– soft brass brushes are good for steel). Scrub in various directions. This removes stuck powder and begins smoothing optimals. Dry cleaning works. For tougher work, use a brush with isopropyl alcohol (IPA) or a specialized steel cleaner. Avoid water unless drying instantly.

Tumbling: This is terrific for several components, specifically complex forms. Place the components in a vibratory tumbler or rotating tumbler. Include rough media like ceramic cones or plastic pellets and a cleaning substance. The rolling action carefully uses down the peaks, smoothing the surface area uniformly. Time differs– start with 30 minutes and check.

Media Blasting: This is faster and extra aggressive. Use a blast closet. Usual media consist of glass beads (for a satin coating), aluminum oxide (for more abrasion), or plastic media (gentler). Blasting powerfully gets rid of surface powder and dramatically minimizes roughness. Readjust stress and media kind based on your desired finish and part strength.

Chemical Cleaning: Specialized remedies can liquify binder deposits (common in bound steel printing) or extremely fine bits. Utilize these with care. Adhere to the supplier’s directions exactly. Rinse parts incredibly well after chemical cleansing, typically with water followed right away by IPA to prevent rust. Dry completely.

Hand Sanding: For accuracy areas or last smoothing. Begin with coarser grit sandpaper (like 120-220) damp or completely dry. Relocate to finer grits (400, 600, 800+) considerably. Sand in one instructions for an uniform look. This requires time but provides fantastic control.

Frequently, you’ll combine methods. Blast or tumble initially for bulk cleansing, then hand sand crucial areas. Constantly clean parts completely after any type of rough action to eliminate produced dirt.

4. Applications for Cleaned Up 3D Printed Steel Parts .

When that roughness is tamed, your steel prints end up being exceptionally functional. Cleaned up parts are ready for functional work. Assume equipments, brackets, engine parts, or customized tools needing smooth mating surfaces and specific measurements. The aesthetic opportunities open as well. Smooth or sleek steel prints make spectacular jewelry, art items, sculptures, and premium decorative items. Proper cleansing is crucial prior to applying various other coatings. Want a tinted anodized coating on light weight aluminum? The surface area requires to be clean and consistent. Planning to paint your titanium bike part? A tidy, slightly rough (yet managed!) surface area helps the paint stick correctly. Electroplating needs an immaculate surface area. Even if you simply desire the bare metal appearance, cleaning ensures it looks willful and professional, not dirty and unfinished. From aerospace prototypes to bespoke cufflinks, cleaning unlocks real possibility.

5. Roughened Steel Publish Cleaning Up Frequently Asked Questions .

Got concerns? Here are quick responses:.

Can I use water to cleanse them? In some cases, yet be really mindful. Numerous metal powders can rust if damp and moist right away and totally . Water is usually made use of in rolling with substances or for rinsing chemicals off. Always follow with IPA (isopropyl alcohol) displacement and complete drying. When unsure, adhere to dry methods or IPA.

Just how smooth can I obtain the surface area? It depends upon the printing technique, the initial roughness, the steel, and your effort. Media blasting provides an uniform matte surface. Rolling offers a smoother, softer feeling. Hand fining sand and brightening can accomplish near-mirror coatings on many metals. But getting it perfectly smooth like machined steel takes considerable job.

Is compressed air enough? Seldom. It’s necessary for eliminating loosened powder inside channels and holes. Yet it won’t remove the surface area roughness or powder integrated onto the surface. Think of it as step one, not the entire procedure.

What’s the fastest technique? For total cleaning and considerable roughness reduction, media blowing up is typically the quickest. Set up the cupboard, blast for a couple of minutes, done. Toppling takes longer however takes care of several parts at once with much less supervision.

Do I require unique chemicals? Not constantly. IPA is a wonderful, secure solvent for general degreasing and last cleaning after water rinse. For bound steel prints or stubborn residues, you might require the details cleaner suggested by your printer or material provider. Never ever use rough arbitrary chemicals.

Can cleansing damages my part? Yes, if you’re also aggressive. Blowing up with overly tough media or high stress can wear down great information. Over-tumbling can round edges exceedingly. Fining sand as well hard can produce irregular areas. Beginning gentle, examination on a scrap piece ideally, and check frequently.

(how to clean roughened 3d printed metallics)

How do I know when it’s tidy enough? Run your finger over it. Does it really feel smooth and consistent, not sandy or dirty? Look carefully under excellent light. Is loose powder gone? Is the surface area structure appropriate for your following action (painting, setting up, display)? If it looks good and feels clean, it probably is.