Discover a professional 3D printing powder supplier

Plastic vs. Titanium: Can 3D Printed Prosthetics Outperform Metal?

(are 3d printed prosthetics better than metal)

Forget bulky sci-fi robots. Imagine a prosthetic limb made just for you. It fits perfectly. It feels surprisingly light. It even looks cool. This is the promise of 3D printed prosthetics. But how do they stack up against the old reliable metal ones? Let’s explore this fascinating battle of materials reshaping lives.

1. What Are 3D Printed Prosthetics?

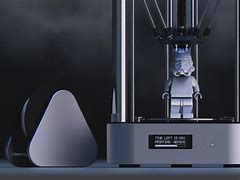

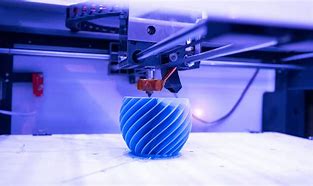

Think of a regular inkjet printer. Instead of ink, it uses plastic, nylon, or even carbon fiber. Instead of paper, it builds objects layer by layer. Apply this to making artificial limbs. That’s 3D printed prosthetics. They are custom-made replacements for missing body parts, like hands, arms, or legs. The process starts with a digital scan of the patient’s limb. Special software then designs the prosthetic around this exact shape. Finally, the printer creates the physical piece. This tech moves beyond simple hooks. It allows for complex designs impossible with traditional metal forging. Think intricate finger joints mimicking natural movement. Think sockets that perfectly hug the remaining limb. Think lightweight structures built with internal honeycombs for strength. This customization is the heart of 3D printing’s appeal. Each piece is unique, designed for one person’s body and needs.

2. Why Consider 3D Printed Prosthetics Over Metal?

Metal prosthetics have been the standard for decades. They are strong and durable. But they come with drawbacks. Weight is a major issue. Carrying several pounds of steel or titanium all day is tiring. It can strain joints and cause discomfort. Cost is another big hurdle. High-end metal limbs can cost tens of thousands of dollars. Many people find them unaffordable, especially children who outgrow them quickly. Getting a good fit with metal can be difficult too. It often involves multiple fittings and adjustments. The process is slow. This is where 3D printing shines. The materials used are much lighter than metal. This means less energy spent moving the limb. It feels more natural. The cost difference is dramatic. 3D printed versions can be made for a fraction of the price of metal ones. This opens doors for more people. The custom fit from scanning is usually superior from the start. Changes are easier and cheaper to make. Speed matters. A new 3D printed limb can be ready in days or weeks, not months. For kids who grow fast, this speed is essential. They can get a new, well-fitting prosthetic quickly. This keeps them active and engaged.

3. How Are 3D Printed Prosthetics Actually Made?

The journey starts with data. A technician uses a 3D scanner. This device captures the exact shape and size of the patient’s residual limb. It creates a precise digital model. Think of it like a highly detailed photograph in 3D. Next comes the design phase. Prosthetists and engineers work together. They use specialized computer software. This software lets them design the prosthetic around the scanned limb model. They can adjust thickness, add grip textures, incorporate ventilation holes, and design functional joints. They choose the best internal structure – often a lattice or honeycomb – for strength without weight. The design is tailored to the patient’s life. An artist might need delicate finger control. A farmer needs rugged durability. A child wants a superhero-themed arm. Once the design is perfect, it’s sent to the printer. The printer reads the digital file. It heats the chosen material, like medical-grade plastic filament. It deposits the material layer by layer, following the design precisely. Each layer bonds to the one below. Over hours, sometimes days, the prosthetic takes shape. After printing, some finishing touches might be needed. This could involve smoothing surfaces, adding padding, or attaching electronic components like sensors or motors for more advanced bionic limbs.

4. Real-World Applications Changing Lives

3D printed prosthetics aren’t just lab experiments. They are making a tangible difference right now. For children, the impact is huge. Kids grow rapidly. A metal prosthetic fitted in January might be too small by June. Replacing it constantly is financially impossible for most families. 3D printing solves this. New limbs can be produced quickly and cheaply as the child grows. Organizations like e-NABLE connect volunteers with printers to kids in need globally. Designers create fun, colorful limbs shaped like dinosaurs or race cars. This reduces stigma. Kids feel proud, not self-conscious. In developing countries, access is critical. Traditional prosthetics are often unavailable or too expensive. Mobile 3D printing labs can travel to remote villages. They scan, design, and print limbs onsite. This brings life-changing technology to people who had no hope before. Veterans benefit too. Modern scanning ensures a perfect fit for complex injuries. The lightweight design reduces strain on damaged bodies. Even for unique situations, 3D printing excels. Custom devices for specific hobbies, like holding a guitar pick or a tennis racket, are easily created. Animal prosthetics are another growing area. Turtles with damaged shells, dogs missing legs, even birds with broken beaks get custom 3D printed solutions.

5. FAQs: Your Burning Questions Answered

Are 3D printed prosthetics as strong as metal? It depends. For heavy-duty tasks, like intense manual labor, metal often wins. Modern printing materials are surprisingly tough. They handle everyday activities well. Think walking, driving, cooking, playing. For kids and most adults, the strength is sufficient. The design matters a lot. Internal structures boost strength without weight. For extreme demands, metal is still king. For daily life, 3D printing holds its own.

How long do they last? They don’t last as long as high-end metal limbs. Metal can last 5-10 years or more with care. A typical plastic 3D printed limb might last 1-3 years. This is okay. They cost much less. Replacing them is easier and faster. For children who outgrow limbs quickly, longevity isn’t the main concern. Adults need to consider their activity level. Heavy users might need replacements sooner.

Can they get wet? Most basic 3D printed limbs use plastics like PLA or ABS. These are somewhat water-resistant. Getting caught in rain is usually fine. Prolonged soaking or swimming is not recommended. Special waterproof materials exist. Sealed designs are possible. Always check the specific materials used in your device. Metal handles water much better.

Do they look realistic? Some can. Silicone covers and detailed painting create very lifelike skin tones and features. But many users, especially kids, prefer bold, non-realistic designs. Bright colors, patterns, even glow-in-the-dark elements are popular. The choice is personal. The tech allows for both realistic and artistic looks.

(are 3d printed prosthetics better than metal)

Who pays for them? Costs vary. Basic designs can be very cheap. Advanced ones cost more. Insurance coverage is improving but inconsistent. Many non-profits provide them free or low-cost. Crowdfunding helps some individuals. The lower price point makes them accessible to people who could never afford metal. This is a major advantage.