Discover a professional 3D printing powder supplier

Can Your Metal 3D Printer Really Handle Aluminum?

(can metal 3d printer print aluminum)

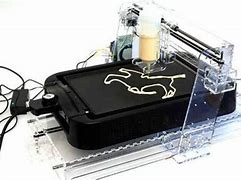

Metal 3D printing sounds like science fiction. Imagine building complex metal parts layer by layer. This technology is real. It offers incredible design freedom. Many people wonder about its limits. A common question pops up: Can metal 3D printers actually print aluminum? The short answer is yes. But it’s not always simple. Let’s explore the fascinating world of printing this vital metal.

Main Product Keywords: Metal 3D Printer, Aluminum

1. What Does Printing Aluminum Mean?

Metal 3D printing builds parts additively. It uses fine metal powder. A powerful energy source fuses the powder. This happens layer by layer. Aluminum is a specific metal. Printing aluminum means using aluminum powder. The printer melts this powder selectively. It forms solid aluminum parts. This is different from casting or machining. It allows complex internal structures. Think of intricate cooling channels inside a solid block. Traditional methods struggle with this. Aluminum printing opens new doors for design. It’s particularly exciting for industries needing lightweight, strong components.

2. Why Print Aluminum? What’s the Big Deal?

Aluminum is everywhere. It’s crucial in aerospace, cars, and consumer gadgets. Why? It offers a fantastic strength-to-weight ratio. Aluminum parts are strong but light. This saves energy in moving vehicles. It improves performance in aircraft. Heat management is another key benefit. Aluminum conducts heat very well. Printed aluminum parts excel in heat exchangers and cooling systems. Design freedom is the third major advantage. Complex shapes impossible to machine become possible. Parts can be optimized for function. Weight can be reduced without sacrificing strength. Printing aluminum also reduces waste. Traditional machining cuts away large amounts of material. 3D printing uses mostly what’s needed. This is more efficient. It saves material costs. Rapid prototyping is easier too. Need a new design? Print it quickly. Test it. Refine it. This speeds up development cycles significantly.

3. How Do Metal Printers Actually Print Aluminum?

Printing aluminum requires specific technology. The most common method is Powder Bed Fusion (PBF). Two main types exist: Laser Powder Bed Fusion (LPBF) and Electron Beam Melting (EBM). LPBF is the most widespread for aluminum. Here’s how it works. A thin layer of aluminum powder spreads across a build platform. A high-power laser scans the powder bed. It follows the cross-section of the part design. The laser melts the powder precisely where needed. The platform lowers slightly. Another layer of powder spreads. The laser melts the new layer. It also fuses it to the layer below. This repeats thousands of times. The part builds up slowly. After printing, the part sits in a cake of unused powder. Workers remove this excess powder carefully. The part then usually needs heat treatment. This relieves internal stresses. It improves the material’s strength. Finally, support structures are removed. The part might need surface finishing. The entire process happens inside a sealed chamber. This chamber is filled with inert gas like argon. Oxygen causes problems. It can oxidize the hot aluminum. This ruins the part. The gas prevents this.

4. Where Are We Using Printed Aluminum Parts?

Printed aluminum parts are finding real homes. The aerospace industry is a major user. Weight savings are critical for planes and spacecraft. Every gram counts. Printed aluminum brackets, housings, and ducting reduce weight. They maintain strength. Formula 1 and other racing teams use printed aluminum. They need custom, optimized parts fast. Lightweight suspension components and heat shields are common. The automotive sector follows. Electric vehicles benefit greatly. Printed aluminum parts manage battery heat. They create lightweight structural elements. Custom cooling systems are printed. Consumer electronics use printed aluminum too. Think of unique heat sinks for high-performance computers. Custom camera housings and drone frames are printed. Medical devices are another frontier. Lightweight prosthetics and surgical tools use printed aluminum. Even the energy sector employs it. Custom heat exchangers for power plants are printed. The applications grow constantly. Anywhere lightweight, strong, complex, or thermally efficient parts are needed, printed aluminum shines.

5. FAQs: Your Aluminum Printing Questions Answered

People have many questions about printing aluminum. Let’s tackle the frequent ones.

Is printed aluminum as strong as cast or machined aluminum? Yes, often stronger. The printing process creates a very fine microstructure. Properly printed and heat-treated aluminum parts meet or exceed standards for cast material. They can match the strength of machined parts from wrought stock.

Which aluminum alloys can be printed? Not all alloys work well. Some common printable alloys are AlSi10Mg, AlSi7Mg, and Scalmalloy®. AlSi10Mg is popular. It offers good strength, hardness, and thermal properties. Research continues on new printable alloys.

Is printing aluminum expensive? It can be. The printers are costly. High-purity aluminum powder is expensive. The process takes time. It often requires post-processing. Printing is best for complex parts, low volumes, or prototypes. It replaces costly tooling for complex shapes. For simple parts, machining is usually cheaper.

What are the main challenges? Printing aluminum is tricky. The powder is highly reflective. It doesn’t absorb laser energy easily. This requires careful laser control. Aluminum powder is also very reactive. It oxidizes quickly if exposed to air during printing. This needs strict atmospheric control. Residual stresses can build up. This requires careful support design and heat treatment. Surface finish might be rough. Post-processing like machining or polishing is often needed.

(can metal 3d printer print aluminum)

How complex can the designs be? Extremely complex. Internal channels, lattices, and organic shapes are possible. This is the biggest design advantage. Freedom from traditional manufacturing constraints allows radical optimization. Think of bone-like structures optimized for load paths.