Discover a professional 3D printing powder supplier

Beyond Plastic: The Steel Revolution in 3D Printing .

(what metals can be used in 3d printing?)

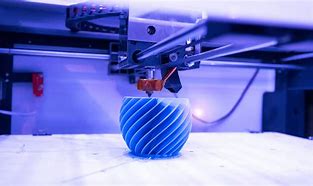

Everyone understands 3D printing makes plastic things. Toys, prototypes, phone situations– it’s all over. But what regarding metal? Can you truly publish solid, functional metal components? The solution is a resounding yes! Metal 3D printing is here, altering exactly how we make whatever from jet engines to clinical implants. It’s not simply a novelty; it’s an effective production device. Allow’s study the remarkable globe of steels you can publish and why it matters.

1. What is Steel 3D Printing? (The Foundation) .

Steel 3D printing is specifically what it seems like: building objects layer by layer utilizing steel. It’s also called Additive Production for steels. Rather than cutting away product like typical machining, it adds material specifically where required. Think of it like welding exceptionally thin layers on top of each other, yet managed by a computer system. The crucial active ingredients are the metal powders. Not just any kind of metal functions. The powder needs particular buildings like size, shape, and flowability. Typical steels used include:.

Titanium: Super strong, lightweight, and biocompatible. Perfect for aerospace and medical implants (like hip replacements).

Stainless-steel: Versatile and strong. Used for tools, equipment parts, and also some consumer goods.

Light weight aluminum: Lightweight and great for warmth transfer. Utilized in automotive components and warm exchangers.

Nickel Alloys (like Inconel): Outstanding for heats and rust resistance. Located in jet engines and gas generators.

Cobalt-Chrome: Another fantastic selection for medical implants and dental work because it’s biocompatible and wear-resistant.

Tool Steels: Used for making sturdy molds, reducing devices, and parts that require high hardness.

Copper: Outstanding for electrical and thermal conductivity. Utilized in warm sinks and electrical elements.

These metals start as great powders. The printer utilizes a warmth resource– typically a laser or electron beam– to thaw the powder in specific places, building the part one layer at once.

2. Why Select Steel 3D Printing? (The Benefits) .

So, why trouble with metal 3D printing? Conventional techniques like spreading or machining job, right? Steel printing offers unique advantages:.

Complexity is Free: Making detailed forms with interior channels, latticeworks, or natural forms is easy with printing. Traditional approaches commonly can’t achieve this, or it costs a fortune.

Lightweighting: Printing enables producing get rid of inner frameworks (like honeycombs) that are strong but utilize much less material. This saves weight, crucial for airplanes and autos.

Product Efficiency: Considering that you only make use of the material required for the component, there’s really little waste compared to machining away a huge block of metal.

Modification: Required a special part? Printing makes it simple and cost-effective to produce one-offs or small sets. Assume tailored clinical implants or specialized devices.

Speed for Prototypes: Obtaining a metal prototype made quickly speeds up style cycles. You can test and iterate much faster.

Combination: Instead of making several components and constructing them, you can commonly print a single, intricate item. This decreases setting up time and potential points of failure.

These benefits make steel printing powerful for particular applications where complexity, weight, or rate are crucial.

3. Just How Does Steel 3D Printing Job? (The Process) .

There are a few primary methods to publish metal. One of the most typical are Powder Bed Combination techniques:.

Careful Laser Melting (SLM): A high-power laser checks over a slim layer of steel powder, melting it precisely according to the component design. The build system lowers, a brand-new layer of powder is spread out, and the procedure repeats.

Direct Metal Laser Sintering (DMLS): Comparable to SLM, yet practically the laser sinters (merges) the powder fragments without constantly completely melting them. The terms are usually used reciprocally.

Electron Light Beam Melting (EBM): Instead of a laser, this makes use of an effective electron beam of light in a vacuum cleaner to thaw the steel powder. It’s often much faster and helpful for particular responsive steels like titanium.

One more technique is Directed Power Deposition (DED): Here, steel powder or cable is fed right into a melt pool produced by a laser or electron light beam. The nozzle walks around, depositing product like welding. This is great for adding attributes to existing components or repairing elements.

After printing, the component is normally still stuck inside a block of unused powder. It obtains eliminated, cleaned, and commonly calls for warm treatment (like stress relieving or solidifying) to accomplish the very best mechanical properties. Some machining or surface area finishing may also be needed.

4. Where is Metal 3D Printing Utilized? (Real-World Applications) .

Steel printing isn’t just a laboratory experiment. It’s materializing parts for requiring industries:.

Aerospace & Protection: Light-weight turbine blades, fuel nozzles with complicated interior air conditioning channels, structural braces. Conserving weight right here straight conserves gas.

Medical & Dental: Customized hip and knee dental implants flawlessly matching an individual’s bone framework, medical tools with unique geometries, dental crowns and bridges. Biocompatible titanium and cobalt-chrome are stars right here.

Automotive: Lightweight parts (braces, heat exchangers), personalized jigs and components for assembly lines, prototypes for brand-new engine parts. High-performance autos use it thoroughly.

Power: Facility components for gas turbines (like blades and vanes), warm exchangers, parts for oil and gas expedition that stand up to extreme conditions.

Tooling: Conformal cooling networks in injection mold and mildews substantially lower cycle times. Resilient device inserts and jigs are likewise printed.

Consumer Goods: High-end bike components, personalized jewelry (using precious metals like gold or silver), special elements for electronic devices.

These applications show steel printing solving real issues: lightening components, allowing brand-new layouts, speeding up manufacturing, and creating custom solutions.

5. Steel 3D Printing FAQs (Common Concerns) .

Let’s tackle some frequent concerns about steel printing:.

Are printed steel parts strong? Yes! Properly published and processed parts can satisfy or perhaps surpass the stamina of commonly made components. They are fully dense and functional.

Is it pricey? The makers and products set you back greater than plastic printers. But for complicated components, or when you consider savings from lightweighting or lowered assembly, it can be cost-effective. The worth remains in the style opportunities.

What are the dimension limitations? Construct volumes differ. Some equipments take care of parts just inches big. Bigger industrial printers can make components several feet long. It depends upon the equipment.

Is it slow down? Printing can take hours or even days for huge, complex parts. But this is usually still faster than conventional manufacturing for those particular components. Post-processing adds even more time.

What concerning surface area coating? As-printed components usually have a rough surface. They normally require finishing like sandblasting, machining, or polishing for smooth surfaces or limited resistances.

Can I print at home? Not truly. Metal printers are industrial devices calling for special handling of powders (safety), high power, controlled atmospheres, and significant competence. It’s not a desktop computer technology yet.

(what metals can be used in 3d printing?)

Are all metals? No. The metal should be offered as a suitable powder, and its buildings (like melting factor) have to collaborate with the printing procedure. Research is ongoing to expand the range.