Discover a professional 3D printing powder supplier

Unlocking Metal 3D Printing: The Filament Change

(what filament is used to 3d print metal objects)

Steel 3D printing sounds like science fiction. Picture structure complicated metal parts layer by layer, directly from a computer documents. However how do you actually print metal? Many individuals presume it includes melting steel cord, similar to plastic printing. The truth includes unique materials called filaments. These aren’t pure steel cables. They are the essential component for one popular method of metal printing. Let’s discover this fascinating innovation and the one-of-a-kind filaments that make it possible.

1. What is Metal Filament? .

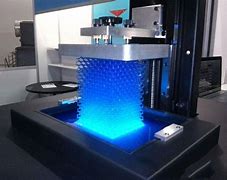

Think about metal filament as steel powder entraped inside a plastic jacket. It feels and look just like normal plastic 3DD printing filament. You can load it into a basic desktop computer 3D printer. The printer thaws the plastic binder material and lays it down layer by layer, similar to printing a plastic component. The big distinction is the little steel fragments combined throughout this plastic. Usual steels include stainless steel, bronze, copper, and also titanium. After printing, the part looks like plastic. It’s typically called a “eco-friendly part”. This environment-friendly component is not the last steel item. It’s simply the very first step. The steel magic takes place later in an unique procedure.

2. Why Usage Filament for Metal Printing? .

Using filament uses huge advantages. The main advantage is expense. Dedicated steel 3D printers can set you back numerous hundreds of dollars. They are intricate machines. Printing with metal filament uses a standard FDM printer. These are more affordable and extensively readily available. This makes steel printing easily accessible to many more people. Small companies, hobbyists, and colleges can afford it. One more benefit is safety and security. Publishing with pure molten metal calls for severe warm and special handling. Steel filament printing occurs at temperature levels similar to normal plastics. It’s more secure and easier to take care of. Filament likewise permits elaborate styles. The printer can produce intricate forms that may be difficult or expensive with conventional metalworking methods. It opens new design possibilities.

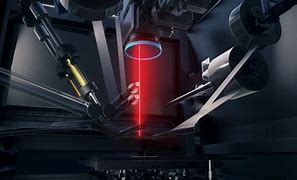

3. Just How Does Steel Filament Printing Work? .

The process entails two primary stages: printing and post-processing. First, you print the object making use of the metal filament. The printer warms the filament. It extrudes the molten plastic binder lugging the steel powder. It constructs the part layer by layer. You end up with a plastic component full of steel powder. This is the eco-friendly part. The environment-friendly part is fragile. It consists of a lot of plastic binder. The following stage removes this binder and integrates the metal bits. This is called debinding and sintering. Debinding eliminates the plastic. This can be done utilizing chemicals or warm. Sintering is the critical action. The part is warmed in a special high-temperature heater. The temperature is high however listed below the metal’s melting factor. The steel fragments bond with each other. The part shrinks considerably during sintering. The plastic binder is gone. What stays is a strong steel component. The final component is porous but strong. It’s a genuine metal things developed from filament.

4. Applications of Metal Filament Printing .

What can you make with this modern technology? The possibilities are growing. Lots of markets locate it helpful. Jewelry manufacturers utilize bronze or copper filaments. They create one-of-a-kind styles and custom items. Musicians utilize it for sculptures and ornamental products. The metal surface gives a costs appearance. Engineering applications are increasing. Companies publish useful prototypes in steel. They check styles prior to committing to pricey production approaches. Small, complex parts for machinery or tools prevail. Fixing damaged components is another use. You can check a busted gear and print a replacement in steel. Enthusiasts take pleasure in making custom tools, blade takes care of, or version parts. The ability to produce small sets or one-off steel items is effective. It supports advancement and personalization.

5. FAQs concerning Steel Printing Filament .

Individuals often have concerns concerning this procedure. Below are some typical ones:.

Is it really steel? Yes. After sintering, the plastic binder is gone. The component is strong metal, though a little porous. It conducts electrical power and has metallic homes.

Exactly how solid is the last component? Toughness depends upon the steel and the sintering high quality. Sintered stainless-steel parts can be quite strong, appropriate for lots of practical applications. They are normally not as solid as solid cast or machined steel, yet good for lots of usages.

Does it need an unique printer? No. You can use a regular FDM 3D printer that takes care of the necessary temperatures. You definitely require a high-temperature sintering heater for the post-processing. The printer alone isn’t sufficient.

Is it costly? The filament costs more than normal plastic filament. Sintering calls for a furnace, which is a financial investment. Nevertheless, the total cost is still much less than industrial steel printers. It’s cost-efficient for small production.

Are there options to filament? Yes. Other steel printing methods exist. Straight metal laser sintering melts metal powder with a laser. Binder jetting uses fluid binding agents. These techniques are different. They often call for much more expensive commercial equipments. Filament offers an extra easily accessible entry point.

(what filament is used to 3d print metal objects)

What regarding completing? Sintered parts frequently have a harsh surface area. You can brighten, plate, or repaint them for a smoother surface. This improves look and feel.