Discover a professional 3D printing powder supplier

Metal Magic: Can 3D Printers Really Craft Solid Steel?

(will there ever be a 3d printer that prints metal)

Imagine building complex metal parts, intricate shapes once impossible, straight from a digital file. Forget carving blocks or pouring molten metal. This is the promise of metal 3D printing. It sounds like science fiction. But is it real? More importantly, is it here to stay? Let’s explore the fascinating world of machines that print metal.

1. What is a Metal 3D Printer?

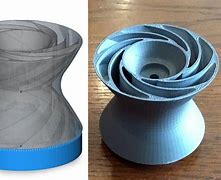

A metal 3D printer is not your average desktop gadget printing plastic toys. It’s a sophisticated machine. It builds solid metal objects layer by layer. It uses high-powered lasers or electron beams. These beams melt fine metal powder. The powder could be titanium, stainless steel, aluminum, or even exotic alloys. Layer by layer, the molten powder fuses together. It builds a complete, dense metal part. Think of it like welding, but controlled by a computer with incredible precision. The result is not a fragile model. It’s a functional metal component ready for real-world use. This technology unlocks new design possibilities. It allows shapes traditional manufacturing simply cannot achieve.

2. Why Use Metal 3D Printing?

Why choose metal 3D printing over older methods like casting or machining? It offers unique advantages. First, it allows incredible design freedom. Engineers can create complex internal channels, hollow structures, or organic shapes. These shapes are often impossible to make otherwise. Second, it reduces waste. Traditional machining cuts away large amounts of material from a solid block. Metal 3D printing only uses the material needed for the part itself. This saves money and resources. Third, it enables rapid prototyping and production. Companies can quickly test new designs without expensive tooling. They can even make custom parts on demand. This is great for specialized applications like medical implants or aerospace components. Fourth, it allows part consolidation. Instead of assembling many small pieces, you can print one complex part. This makes assemblies stronger and lighter. Finally, it can work with difficult metals. Some super-strong alloys are hard to machine. Metal 3D printing handles them more easily.

3. How Does Metal 3D Printing Work?

Several techniques exist. The main ones are Powder Bed Fusion techniques. Think Selective Laser Melting (SLM) or Direct Metal Laser Sintering (DMLS). Here’s how it works. A thin layer of fine metal powder spreads across a build platform. A powerful laser scans the powder bed. It follows the cross-section of the part design. The laser melts the powder particles exactly where needed. The melted particles fuse together and to the layer below. The platform lowers slightly. Another layer of powder spreads on top. The laser melts this new layer, bonding it to the previous one. This repeats hundreds or thousands of times. It builds the entire part embedded in unused powder. After printing, the part cools inside the machine. Workers remove the part from the powder bed. They then clean off the excess powder. Often, parts need further heat treatment. This relieves stresses and improves strength. Finally, some machining or surface finishing might be needed. Other methods exist too. These include Directed Energy Deposition (DED), where metal powder or wire is fed into a melt pool created by a laser or electron beam, and Binder Jetting, where a liquid binder glues powder together before sintering. Each method has its strengths for different applications.

4. Applications of Metal 3D Printing

Metal 3D printing is moving beyond prototyping. It’s making real parts for demanding industries. Aerospace is a major user. Companies print lightweight, strong components for jet engines and spacecraft. Think fuel nozzles, turbine blades, and structural brackets. These parts often weigh less and perform better than traditionally made ones. The medical field uses it too. Surgeons implant custom titanium hip joints or cranial plates tailored to a patient’s unique anatomy. Dentists use it for precise crowns and bridges. The automotive industry employs it for high-performance parts. This includes custom engine components and lightweight suspension parts, especially in racing. Tooling manufacturers create complex injection molds with internal cooling channels. These channels improve production efficiency. Even jewelry designers print intricate pieces in precious metals like gold and platinum. The energy sector uses it for parts in turbines and drilling equipment. As the technology matures and costs decrease, we’ll see it in more everyday products. Expect more durable consumer goods and custom hardware.

5. FAQs About Metal 3D Printers

People have many questions about this amazing technology. Here are some common ones:

Can I buy a metal 3D printer for home? Not really. Industrial metal printers are large, expensive machines. They require significant power, special gases, and strict safety measures due to lasers and fine metal powder. Desktop metal printers exist but are still costly and complex. They are mostly for businesses and labs.

Is it strong? Absolutely. Properly printed and processed metal parts can be as strong, or sometimes stronger, than parts made by casting or forging. The material properties are excellent. They meet demanding industry standards.

How much does it cost? Metal 3D printing is expensive. The machines cost hundreds of thousands of dollars. The metal powders are pricey. Post-processing adds more cost. It’s best for high-value parts, complex designs, or low-volume production. Costs are coming down, but it’s not cheap yet.

What metals can it print? Many common metals work: stainless steel, titanium, aluminum, cobalt-chrome, nickel alloys, and even precious metals like gold and silver. Research continues into new printable alloys constantly.

(will there ever be a 3d printer that prints metal)

Are there size limits? Yes, but they are growing. Industrial printers can make parts over a meter long in some cases. Larger systems are being developed. For very big structures, techniques like wire arc additive manufacturing are used.