Discover a professional 3D printing powder supplier

The Data Pulse Inside 3D Metal Printing

(how 3d metal printing uses data)

1. What is 3D Metal Printing?

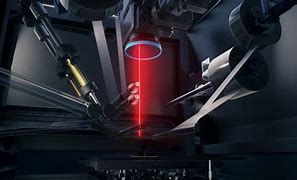

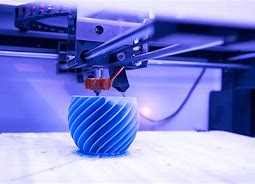

Think about building something complex, like a jet engine part or a custom medical implant. Traditionally, making these involves cutting away metal from a solid block. This is subtractive manufacturing. 3D metal printing, known as metal additive manufacturing (AM), flips this idea. It builds objects layer by layer directly from digital designs, adding material only where needed. It’s like printing, but instead of ink on paper, it’s melting metal powder with lasers or electron beams to create solid, intricate shapes. This method unlocks possibilities for designs impossible through older techniques. Think internal cooling channels inside turbine blades or lightweight, lattice structures for aerospace parts. Data is the essential starting point for every single part made this way.

2. Why is Data So Critical for 3D Metal Printing?

3D metal printing isn’t just pressing a button. It’s a complex, high-precision process. Tiny mistakes can lead to big problems. Faulty parts might break under stress or fail in critical applications. Data acts as the guiding force, the recipe, and the quality controller all rolled into one. First, the digital design file provides the exact blueprint. Without this precise data, the printer wouldn’t know where to place the material. Second, the printing process itself generates huge amounts of data. Sensors monitor everything: the temperature inside the build chamber, the laser’s power and focus, the speed of the powder recoater, even the oxygen levels. This constant data stream ensures the machine operates within strict parameters. If anything drifts off course, the system can alert operators or even make adjustments automatically. Without this constant data feedback loop, achieving consistent, high-quality metal parts would be incredibly difficult and risky. Data minimizes waste, reduces failed builds, and ensures the final part meets exact specifications.

3. How Does Data Drive the 3D Metal Printing Process?

Data is involved at every single stage. It starts with the 3D Computer-Aided Design (CAD) model. This digital file defines the part’s geometry. Software then slices this model into hundreds or thousands of ultra-thin layers, creating a detailed path for the printer’s laser or electron beam to follow. This sliced data is sent to the printer. Once printing begins, a network of sensors kicks into action. High-resolution cameras might watch the melt pool where the laser fuses the powder. Infrared thermometers constantly measure temperatures across the build plate. Position sensors track the movement of the laser head and the powder distribution system. All this real-time data flows back to the printer’s control system. This system compares the live data against the ideal parameters set for that specific material and part design. If the temperature gets too high in one spot, the laser power might be adjusted automatically. If a layer doesn’t look right, the build might be paused for inspection. After printing, the data journey continues. Scanners might check the part’s dimensions against the original CAD model. Further data analysis might predict potential internal stresses or weaknesses based on the thermal history recorded during printing. This data guides post-processing steps like heat treatment.

4. Applications Powered by Data-Driven Metal Printing

The unique capabilities unlocked by 3D metal printing, fueled by data, are transforming industries. In aerospace, companies print lightweight, high-strength components like turbine blades and fuel nozzles. These parts often feature complex internal cooling passages impossible to machine traditionally. The data ensures these intricate features are built perfectly every time. The medical field benefits hugely. Surgeons can now have patient-specific implants, perfectly matching bone structures, designed using CT scan data and printed in biocompatible metals like titanium. This leads to better outcomes and faster recovery. The automotive industry uses metal printing for high-performance parts, custom tools, and even prototyping new engine designs quickly. Data allows for rapid iteration and optimization. Even the energy sector leverages it for durable parts in harsh environments, like components for oil and gas extraction or next-generation heat exchangers. The ability to create complex geometries and tailor parts precisely, guided by robust data, opens doors across manufacturing.

5. FAQs About Data in 3D Metal Printing

Q: What kind of data does a 3D metal printer collect?

A: Printers gather massive amounts of data. This includes machine parameters like laser power, speed, and focus. Environmental data like chamber temperature and gas flow rates. Process data such as melt pool size and temperature captured by cameras and pyrometers. Layer data showing exactly what was printed. It’s a comprehensive digital record of the entire build.

Q: Can you print any metal using this method?

A: Not exactly. The most common materials are titanium alloys, stainless steels, nickel-based superalloys, aluminum alloys, and tool steels. Specific printers and processes are optimized for certain material groups. The data parameters (like laser settings) are unique to each material type.

Q: How accurate is 3D metal printing?

A: Accuracy is very high, often within fractions of a millimeter. This precision relies heavily on the quality of the original CAD data and the precise control during printing, maintained by constant sensor feedback and data analysis. Post-build inspection data confirms this accuracy.

Q: Is data used after the part is printed?

A: Yes. Data is crucial even after printing. Scanners compare the finished part to the digital model. Data from the printing process helps determine the best post-processing steps, like heat treatment temperatures and times, to achieve the desired material properties. Data also helps trace part history for quality assurance.

Q: Does all this data make 3D metal printing expensive?

(how 3d metal printing uses data)

A: The technology itself involves significant investment. The data systems add complexity. However, the data also brings major benefits. It drastically reduces the risk of expensive failed builds by catching errors early. It enables the creation of parts that save weight, improve performance, or are otherwise impossible to make, offering value that can outweigh the costs. Data helps optimize the process over time.