Discover a professional 3D printing powder supplier

Title: Before the Buzz: The Unsung Heroes of Steel Forming .

(what came before 3d metal printing)

Intro .

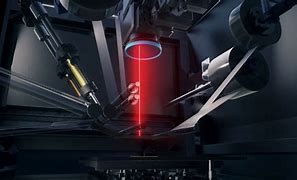

Visualize crafting elaborate metal components layer by layer. That’s 3D steel printing today. But what came prior to this modern magic? Exactly how did designers produce complex metal parts? The journey wasn’t always lasers and powders. It included older, frequently resourceful approaches. These methods prepared. They solved issues for decades. Allow’s explore the interesting world prior to 3D metal printing took spotlight.

Subheading 1: What Came Before 3D Metal Printing? (Conventional Steel Construction Approaches) .

1. People required metal components long before 3D printers. They made use of different approaches. These approaches are often called traditional steel manufacture. They include forming solid metal or joining items.

2. Subtractive procedures were vital. Assume CNC machining. This makes use of computer-controlled tools. The devices removed metal from a strong block. It resembles forming. You remove material to expose the final form. This is exact. It functions well for several parts.

3. Forming processes formed metal without cutting. Metal marking usages passes away. Dies are like heavy-duty mold and mildews. A press knocks the steel sheet right into the die. This shapes it rapidly. Believe auto body panels. Building heats up metal until soft. After that, hammers or presses pound it into form. This makes parts extremely strong. Think wrenches or crankshafts.

4. Joining processes constructed separate items. Welding melts steel sides together. This creates an irreversible bond. Brazing and soldering usage a filler steel. The filler thaws at a reduced temperature. It signs up with parts without melting them totally. Captivating uses metal pins. These pins hold parts together mechanically.

5. Casting put liquid steel into molds. The metal cools down and strengthens inside the mold. This duplicates the mold and mildew’s form. Sand casting makes use of packed sand mold and mildews. Financial investment casting makes use of wax patterns coated in ceramic. The wax melts away. Metal loads the area. This enables complex shapes. Die spreading pressures steel under stress into metal mold and mildews. It’s quick and helpful for automation. Think engine blocks or gear real estates.

Subheading 2: Why Look Back at Pre-3D Metal Techniques? (Understanding the Structure) .

1. Why trouble with old approaches? Aren’t they dated? Really, no. Comprehending them is vital. They are the structure. 3D metal printing didn’t appear from slim air. It built upon existing knowledge.

2. These typical methods addressed actual troubles. They met the needs of their time. They generated trustworthy components. Industries like auto and aerospace relied on them. They still do for lots of applications.

3. Understanding the limitations of older methods assists. It shows why 3D printing ended up being appealing. Typical techniques typically require great deals of tooling. Passes away and mold and mildews cost money and time to make. They are inflexible. Altering a layout means changing the tooling. This is pricey and slow-moving.

4. Subtractive techniques like machining waste material. You begin with a huge block. You removed most of it. This creates scrap. It can be inefficient for complicated parts. Developing and casting have design limitations. Undercuts or interior channels are difficult or impossible.

5. Seeing these difficulties describes the promote something brand-new. 3D steel printing guaranteed less waste. It used layout flexibility. It can make forms traditional techniques couldn’t. It reduced the demand for expensive tooling. Recognizing the “why” behind 3D printing’s rise begins with its precursors.

Subheading 3: Exactly How Did We Shape Metal Before 3D Printing? (The Auto Mechanics of Older Techniques) .

1. Just how did these typical approaches really function? Allow’s look closer at a couple of key players. CNC machining is a subtractive giant. A computer program overviews reducing devices. Devices like drills, mills, and lathes get rid of steel exactly. The equipment complies with electronic directions. It carves the component from strong supply. This requires skilled programs. It likewise needs the right tools.

2. Steel spreading is a various beast. It’s an additive process in a manner. However not layer by layer like 3D printing. Initially, you make a mold and mildew. This is the negative form of the preferred part. For sand spreading, you pack sand around a pattern. You remove the pattern. This leaves a dental caries. You put liquified metal right into this cavity. It cools. You escape the sand. The metal part is within.

3. Investment casting is much more accurate. You make a wax reproduction of the component. You dip it in liquid ceramic. This develops a shell. You melt out the wax. You put molten metal into the hollow ceramic shell. After cooling down, you break short the shell. This leaves a comprehensive metal component.

4. Steel forming uses force. Stamping uses a press equipment. It holds two halves of a die. You place a steel sheet in between them. The press slams shut. The die shapes the sheet quickly. Forging heats up steel. This makes it flexible. Then, hammers or presses warp it. This straightens the steel’s grain structure. It makes the part more powerful.

5. Each technique has its own actions. Each needs specific skills and tools. Machining requirements machine shops. Casting needs shops. Marking and creating demand heavy presses. These were the factories of the past. They formed the metal globe we stayed in.

Subheading 4: Applications: Where Were These Techniques Used? (Pre-3D Printing Steel Components in Action) .

1. Where did we see these pre-3D printing metal parts? Almost everywhere! They developed the backbone of market. Allow’s see some examples.

2. Automotive counted greatly on them. Engine obstructs? Usually sand actors. Transmission instances? Die cast. Car body panels? Steel stamped. Suspension components? Often built. These methods generated parts by the millions.

3. Aerospace made use of financial investment casting. This made complex turbine blades for jet engines. It supplied the required precision and warmth resistance. Aircraft architectural parts could be machined from strong billets. Or they might be forged for stamina.

4. Consumer goods depended upon these techniques. Cooking area appliances utilized stamped steel housings. Devices like hammers and wrenches were created. Fashion jewelry commonly made use of financial investment casting for intricate styles. Also easy points like door joints entailed stamping or casting.

5. Industrial machinery had lots of generally made parts. Gears were usually machined or created. Pump housings were cast. Machine frameworks were welded structures. These approaches built the equipments that built other things. They were essential for years. They still are for numerous standard parts.

Subheading 5: Frequently Asked Questions: Usual Inquiries Regarding Pre-3D Steel Techniques .

1. Were these older techniques completely replaced by 3D metal printing? No, certainly not. Many standard approaches are still widely utilized. They are usually faster and cheaper for high-volume manufacturing. They are trustworthy. For several conventional parts, they continue to be the best choice. 3D printing includes brand-new opportunities. It does not erase the old ones.

2. Is 3D metal printing simply quicker? Not always. For straightforward shapes, typical approaches can be much faster. Especially in automation. 3D printing beams with intricate geometries. It stands out for models and reduced volumes. It reduces tooling prices. Rate depends upon the part and quantity.

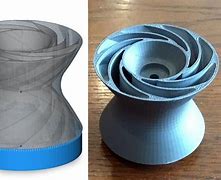

3. Could older approaches make complicated parts like 3D printing? They had limitations. Financial investment casting could make really intricate shapes. Yet it still had some limitations. Internal channels or moving components inside a solid item were impossible. 3D printing breaks these obstacles. It builds interior functions layer by layer.

4. Was the top quality even worse before 3D printing? Not always. Built components are unbelievably strong. Cast parts can be outstanding. Machined parts have fantastic accuracy and surface area finish. 3D printed metal components are catching up. They can be very solid now. Yet standard approaches establish high requirements for material buildings.

(what came before 3d metal printing)

5. Why did we need 3D steel printing then? It addressed specific problems. It allowed unmatched style freedom. It made it possible for complicated air conditioning channels inside engine parts. It made light-weight latticework frameworks possible. It lowered waste for complex shapes. It sped up prototyping. It removed tooling costs for custom components. It filled voids the old approaches could not.