Discover a professional 3D printing powder supplier

Okay, here is the revised blog post based upon your directions.

(could you place metal rods in 3d printed parts to reinforce them?)

Title: Steel Rods: Your 3D Prints’ Secret Strength Boost .

Key Item Keywords: Metal Rods.

( 1) What Are Steel Rods Doing in My 3D Prints? .

Think of your 3D printed component. It’s most likely made from plastic. Plastics like PLA, ABS, or PETG are wonderful. They let us make almost anything. Yet sometimes, plastic alone isn’t strong enough. It can bend. It can break. It could not hold hefty things. That’s where steel poles come in. It’s an easy concept. You put metal poles inside the plastic part while you’re publishing it. Or possibly you add them after. These rods imitate a covert skeleton. They give additional stamina precisely where you require it. It resembles including rebar to concrete. The plastic holds the form. The steel rod takes the heavy loads. This technique is called support. It makes your 3D prints a lot harder without making them much heavier. You can utilize various type of rods as well. Steel poles are really strong. Light weight aluminum rods are lighter. Brass poles are simple to reduce. The choice relies on what you need.

( 2) Why Bother Reinforcing Prints with Steel Rods? .

Why most likely to this additional trouble? The primary reason is strength. Pure plastic components have limits. They are great for lots of things. Yet in some cases you need extra. Possibly you’re making a brace. It requires to hold weight. Maybe it’s a device take care of. It obtains a lot of force. Possibly it belongs for a device. It has to not damage. Including steel poles inside makes these components much stronger. They resist bending much better. They handle impacts better. They last longer. It’s additionally commonly cheaper and faster than publishing everything in super-strong, pricey materials. You can utilize your typical filament. Then simply include toughness where it matters with the rods. This technique is also great for fixing vulnerable points. Slim areas or lengthy periods in a print are frequently weak. Including a rod along that weak area makes it solid. It avoids cracking. You get an even more reliable part.

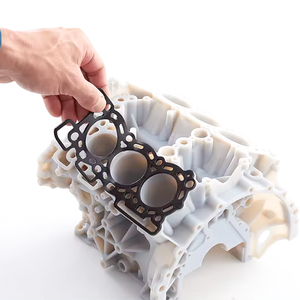

( 3) Just How Do You Really Put Poles Inside 3D Prints? .

Okay, you want to attempt this. Just how do you do it? You have a couple of alternatives. The easiest method is to pause your printer. You create your part in your 3D modeling software application. You know where you want the rod. You leave an opening or a network because spot. Begin printing the component. When the printer reaches the layer just below where the opening starts, pause it. Thoroughly put the metal rod right into the opening. Ensure it rests directly. Then reboot the printer. The printer proceeds laying plastic over the pole. It encloses the rod inside the component. One more means is to publish the get rid of the channel currently there. After that you slide the pole in after the print is done. You may need to glue it in place. Some people even make unique ports. These ports hold the rod well without adhesive. You need to obtain the dimension right. The opening should be a little bit larger than the pole. This makes it easy to place. However not so huge it wobbles. Making use of poles with a harsh surface area assists. It offers the plastic something to hold onto. Usual pole dimensions are things like 3mm, 5mm, or 1/4 inch. You can find these quickly.

( 4) Where Can You Use This Steel Rod Support Trick? .

This method benefits numerous things. It’s extremely useful for functional components. Components that need to work hard. Consider brackets and mounts. These hold things up. Including a pole makes them much stiffer. It stops them from sagging or damaging. Tool takes care of advantage too. Drills, screwdrivers, even hammers get a lot of force via the handle. A steel rod down the facility makes the manage extremely solid. It will not break. For equipments and robotics, numerous components move or carry tons. Joints, arms, equipments real estates– reinforcing these with poles makes them harder. They can take care of extra stress and anxiety. Leisure activity projects often need stamina. Believe RC automobile components, drone frameworks, or custom jigs. Strengthening these makes them last much longer. Even ornamental products can utilize it. Possibly a big sculpture requires internal support. A metal pole helps it stand tall without bending. It’s a functional strategy. At any time your print really feels a bit flimsy, take into consideration a covert steel pole.

( 5) FAQs: Metal Rods in 3D Prints .

Individuals frequently ask questions concerning this. Here are some usual ones:.

Does it make the print much heavier? .

Not really. The poles include some weight. However it’s normally extremely little compared to the toughness gain. A slim steel pole does not evaluate much. The component gets a lot stronger without coming to be heavy.

Will the plastic melt around a hot rod? .

Most likely not. Steel rods do not fume just resting inside plastic. If your component gets really warm in use, like near an engine, think about it. The plastic might soften. The rod might get hot too. For regular room temperature usage, it’s great.

What pole dimension should I use? .

Beginning tiny. Try rods around 2mm to 5mm size. See just how it works. Suit the rod size to the part size and the load. A small part might utilize a 1mm pole. A large bracket could require a 10mm rod. Experiment to locate what jobs best for your job.

Do I require unique adhesive? .

In some cases. If you move the rod in after printing, adhesive helps. Utilize a strong glue like epoxy. Super adhesive (CA glue) functions okay too. If you stop the printer and installed the rod while printing, glue isn’t needed. The warm plastic melts around it and holds it tight.

Can I make use of other things besides poles? .

(could you place metal rods in 3d printed parts to reinforce them?)

Yes! The concept is to add strength inside. You might use carbon fiber rods. They are very strong and light. Fiberglass poles work as well. Even wood dowels can include some tightness for light tons. Steel poles are common and effective. But you have choices.