Discover a professional 3D printing powder supplier

Okay, here is the blog post crafted as requested.

(what do you call 3d metal printing)

The Magic of Melting Metal: Your Guide to 3D Metal Printing

People talk about 3D printing a lot. You hear about plastic toys and fancy gadgets. But what about making things out of metal? That sounds tougher. It is tougher. Yet, it’s happening. This is 3D metal printing. It’s also called metal additive manufacturing. Let’s dive into this world of building with melted metal.

No. 1 What is 3D Metal Printing?

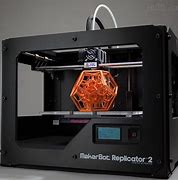

Think of regular 3D printing. It builds objects layer by layer. Usually, it uses plastic. 3D metal printing does the same thing. But it uses metal. It melts metal powder instead of plastic. It uses powerful lasers or electron beams. These heat sources melt tiny metal particles. The machine adds layer upon layer of this melted metal. Slowly, a solid metal part takes shape. It’s not like carving away material. It’s about adding material precisely where needed. That’s the core idea. Several different methods exist. DMLS (Direct Metal Laser Sintering) is common. SLM (Selective Laser Melting) is another. EBM (Electron Beam Melting) uses a different heat source. Binder Jetting uses a glue-like binder first. Then it heats the part later to fuse the metal. All these techniques aim for the same goal: creating complex metal shapes directly from a computer file.

No. 2 Why Choose 3D Metal Printing?

Why bother with this complex process? Regular metalworking works fine. Machines cut metal. They bend it. They weld it. These methods are tried and true. So why change? 3D metal printing offers unique advantages. First, it creates complex shapes easily. Think about intricate cooling channels inside an engine part. Or lattice structures inside a component to make it lighter. These are hard or impossible with traditional methods. 3D printing builds them layer by layer. No problem. Second, it minimizes waste. Traditional machining starts with a block of metal. It cuts away most of it to make the part. This creates a lot of scrap metal. 3D printing uses only the metal needed for the part itself. Very little waste is left. Third, it allows for customization. Need a part slightly different? Change the digital design. Print it. No need for expensive new tools or molds. This is great for prototypes. It’s also good for small batches of specialized parts. Finally, it can combine materials. Some printers can mix different metal powders. This creates unique properties in the final part.

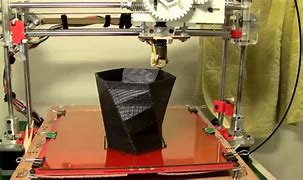

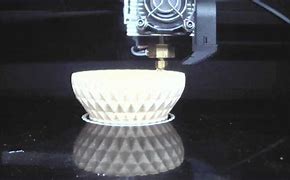

No. 3 How Does 3D Metal Printing Work?

The process starts digitally. An engineer designs the part using CAD software. This software creates a 3D model. The model gets sliced into thin layers by special software. These slices become instructions for the printer. Inside the printer, a thin layer of fine metal powder spreads across a build platform. A powerful laser or electron beam moves across this powder layer. It follows the pattern of the first slice. Where the beam hits, the metal powder melts and fuses together. After one layer is done, the build platform lowers slightly. A new layer of powder spreads over the first. The laser or beam melts this new layer. It also bonds it to the layer below. This cycle repeats hundreds or thousands of times. Layer by layer, the metal object grows upwards. After printing, the part is still hot. It’s also buried in unused powder. Technicians remove the part from the machine. They let it cool down carefully. Then they remove the excess powder. The part might look finished. Often, it needs more work. It might need heat treatment to relieve internal stresses. It might need machining for precise surfaces. Sometimes, it requires polishing. This post-processing is a crucial step.

No. 4 Where is 3D Metal Printing Used?

This technology is powerful. It’s finding its way into many industries. Aerospace loves it. Planes and rockets need strong, lightweight parts. 3D metal printing delivers. It makes complex engine components. It creates lighter brackets and housings. Weight savings here mean fuel savings. Medical fields use it too. Think about custom implants for bones or joints. Every patient is different. 3D printing can create implants tailored exactly to a person’s body. It uses biocompatible metals like titanium. Dental labs use it for crowns and bridges. The automotive industry adopts it. It helps make high-performance parts for racing cars. It also helps create prototypes for new car models faster. Tooling is another area. Molds for plastic injection often need complex cooling channels. 3D printing builds these channels right into the mold. This makes the molding process faster and more efficient. Even the energy sector uses it. It prints parts for turbines and power generation equipment. The applications keep growing.

No. 5 FAQs: Your Burning Questions About 3D Metal Printing

(what do you call 3d metal printing)

Is 3D metal printing expensive? Yes, it often is. The machines cost a lot. The metal powders are pricey. The process itself takes time. It usually makes sense for complex parts. Or for small batches. Or when you need the unique design freedom it offers. Mass production of simple parts is still cheaper with traditional methods. Is it strong? Parts made with 3D metal printing can be very strong. They can match or sometimes exceed the strength of cast or forged metal. It depends on the metal used. It also depends on the printing process. Post-processing like heat treatment is important too. What metals can you print? Many metals work. Common choices include stainless steel, titanium, aluminum, nickel alloys (like Inconel), and cobalt-chrome. New materials are constantly being developed. Is it safe? Printing metal involves high heat and fine powders. Operators need proper training. They need protective equipment. Machines have safety features. Good ventilation is essential. Dust management is critical. Can I print anything? Not quite. Design rules exist. Overhanging structures need support during printing. Walls can’t be too thin. Holes need specific shapes. Engineers learn how to design parts specifically for this process. It’s different from designing for machining.