Discover a professional 3D printing powder supplier

Okay, here is the blog post written according to your specifications.

(what instituion would be most effected by 3d metal printing)

Which Industry Will 3D Metal Printing Rock First?

Imagine building complex metal parts. Forget giant factories. Forget months of waiting. Picture a machine humming quietly. Layer by layer, it builds intricate shapes directly from a digital file. This is 3D metal printing. It’s not just a new tool. It’s a potential earthquake for entire industries. But which sector will feel the tremors first? Which institution stands to gain or lose the most? Let’s dive in.

1. What is 3D Metal Printing?

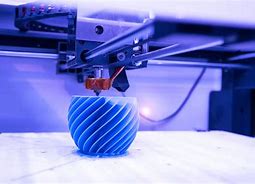

Think of regular 3D printing. It builds things layer by layer using plastic. 3D metal printing does the same thing. But it uses metal powder instead. Powerful lasers or electron beams melt the powder. They fuse it together precisely. This builds solid metal objects directly from a computer design. No molds. No cutting away excess material. It’s called Additive Manufacturing (AM). This is different from traditional “subtractive” methods. Subtractive methods start with a block of metal. They cut bits away to make the final shape. 3D metal printing adds material only where it’s needed. This opens up amazing possibilities. Complex geometries become possible. Parts can be lighter, stronger, and designed in ways impossible before.

2. Why is 3D Metal Printing a Game-Changer for Institutions?

Several institutions will feel the impact. But one stands out: Manufacturing. Traditional manufacturing relies on established methods. These methods often need expensive tooling. Think molds, dies, and specialized machines. Setting these up takes time and money. It also limits flexibility. Changing a design means changing the tooling. That’s costly and slow. 3D metal printing changes this. It allows for rapid prototyping. Companies can test designs quickly. They can iterate faster. It enables mass customization. You can make small batches of custom parts. This is economical. Traditional methods struggle with this. It shortens supply chains. Parts can be printed on-site. You don’t need to ship components globally. This reduces lead times and inventory costs. It unlocks new design possibilities. Parts can be optimized for strength and weight. They can combine multiple components into one printed piece. This simplifies assembly. For manufacturing, this means agility, cost savings, and innovation. It forces a rethink of how things are made.

3. How Does 3D Metal Printing Actually Work?

The process starts with a 3D computer model. Software slices this model into super thin layers. The printing machine spreads a fine layer of metal powder onto a build platform. A high-power laser or electron beam then moves across the powder bed. It selectively melts the powder according to the slice data. This creates a solid layer. The build platform lowers slightly. Another layer of powder is spread. The laser melts this new layer. It fuses it to the layer below. This repeats layer by layer. The part builds upwards inside the machine. Once finished, the part is removed. It’s often encased in unused powder. This powder supports the structure during printing. After removal, support structures might need removal. The part usually undergoes heat treatment. This relieves internal stresses. It improves the metal’s properties. Finally, some surface finishing might be needed. Different metals can be used. Titanium, aluminum, stainless steel, and nickel alloys are common. Each material has specific properties. They suit different applications.

4. What are the Real-World Applications Shaking Up Institutions?

The applications are exploding. They are transforming how institutions operate:

Aerospace & Defense: Weight is critical here. 3D printing makes lighter, stronger parts. Think turbine blades, fuel nozzles, and structural components. Reducing weight saves fuel. It increases payload capacity. Complex cooling channels inside parts improve performance. Repairing high-value parts becomes feasible.

Medical & Dental: Customization is key. 3D printing creates patient-specific implants. Hip joints, cranial plates, and spinal devices fit perfectly. Surgical tools can be designed for specific procedures. Dental crowns and bridges are printed rapidly. Biocompatible metals like titanium are ideal.

Automotive: Car makers use it for prototyping. They also use it for high-performance parts. Think lightweight brackets, customized engine components, and even parts for classic car restoration. It speeds up innovation cycles. It enables low-volume production for specialty vehicles.

Energy: Turbine components for power generation benefit. Oil and gas industries use printed parts for drilling tools. These tools endure extreme conditions. Custom heat exchangers improve efficiency.

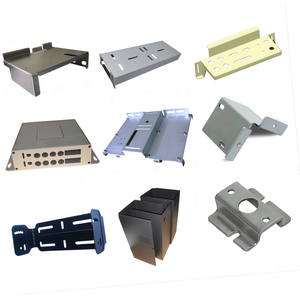

Tooling & Manufacturing: This is a big one. Factories print custom jigs, fixtures, and molds on demand. These tools guide assembly or shape parts. Printing them is faster and cheaper than traditional machining. It reduces downtime. It allows for tool design optimization. This boosts overall factory productivity significantly.

These applications show the shift. Institutions aren’t just adopting a new machine. They are redesigning processes and products.

5. FAQs: Your Burning Questions About 3D Metal Printing’s Impact

People have questions about this technology’s real impact:

Is it really cheaper? It depends. For simple parts made in high volumes? Traditional methods often win. For complex parts, low volumes, or custom items? 3D printing can be cheaper. It saves on tooling costs. It reduces material waste. It cuts down on assembly steps. The total cost picture is changing.

Are the parts strong enough? Yes. Properly printed and processed parts meet demanding standards. Aerospace and medical applications prove this. The strength can match or even exceed traditional parts. Design optimization often makes them stronger and lighter.

Is it fast? Printing one complex part can be faster than machining it. Setting up the print is relatively quick. Mass-producing thousands of identical parts? Injection molding or stamping are usually faster. But for prototypes or small batches, speed is a major advantage.

What about material choices? The range is growing constantly. From common steels to exotic superalloys. New materials are being developed specifically for AM. Properties like heat resistance and strength are key factors.

(what instituion would be most effected by 3d metal printing)

Who’s adopting it fastest? Industries needing high-value, complex, or customized parts lead the way. Aerospace, medical, and high-end automotive are front-runners. Tooling within manufacturing plants is another rapid adoption area. The technology is spreading fast.