Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

Overview of CNC Machining 3D Printing Service Engineering Plastic 3D Printing CNC

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of CNC Machining 3D Printing Service Engineering Plastic 3D Printing CNC

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(CNC Machining 3D Printing Service Engineering Plastic 3D Printing CNC )

Specification of CNC Machining 3D Printing Service Engineering Plastic 3D Printing CNC

Our design plastic 3D printing and CNC machining solutions create strong, practical components. We use tough plastics like Nylon, ABS, PC, PEEK, and POM. These products deal with warmth, chemicals, and wear well. They are good for demanding work.

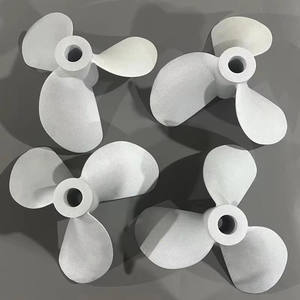

3D printing builds parts layer by layer straight from your electronic documents. This approach is quick for models and complicated shapes. We offer FDM and SLS printing. FDM utilizes dissolved filament. SLS makes use of powdered material merged by a laser. Both techniques generate durable plastic components.

CNC machining cuts strong plastic obstructs into precise shapes. Machines get rid of product with sharp tools led by computer programs. This process offers excellent precision and smooth coatings. It is optimal for last components requiring limited resistances. We machine many engineering plastics efficiently.

These services help you make parts rapidly. Get models fast to examine designs. Produce strong end-use parts prepared for real-world use. We take care of small batches or larger production runs. Our objective is to provide quality parts that satisfy your exact demands. This saves you money and time.

We provide various coatings. Components can be left as-machined or sanded smooth. Painting or other finishes are feasible as well. You select the look needed for your application. We deal with lots of industries. Automotive, aerospace, medical, and consumer goods companies utilize our parts. Our plastics replace metal in many cases. They are lighter and withstand rust well.

(CNC Machining 3D Printing Service Engineering Plastic 3D Printing CNC )

Applications of CNC Machining 3D Printing Service Engineering Plastic 3D Printing CNC

CNC machining and 3D printing services provide powerful remedies for making parts. Businesses utilize them for models and production. These techniques produce complicated shapes quickly. They are vital in numerous markets.

The automotive market counts on these modern technologies. They make custom-made parts for testing new automobile designs. They likewise produce solid, specific components for engines and interiors. This helps cars do better. Aerospace firms need lightweight, long lasting components. CNC machining and 3D printing deliver these. They develop complex airplane elements successfully. This conserves money and time.

Medical device production benefits substantially. CNC machining crafts accurate surgical devices. 3D printing builds personalized prosthetics and implants. This boosts patient treatment. Electronics suppliers utilize these solutions also. They produce detailed housings and connectors. This makes sure devices function dependably.

Engineering plastic 3D printing is specifically useful. It makes challenging, heat-resistant parts. These components hold up against requiring problems. Usual materials consist of ABS, nylon, and polycarbonate. These plastics are solid and versatile. CNC machining deals with steels and plastics. It offers excellent surface coatings and limited tolerances. Both techniques offer rapid turnaround times. This quickens product growth.

Business pick these solutions for their flexibility. They support both tiny batches and huge production runs. This versatility is vital for contemporary manufacturing. The outcome is top notch components on-line.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of CNC Machining 3D Printing Service Engineering Plastic 3D Printing CNC

What materials can you work with? We handle many engineering plastics. ABS, nylon, polycarbonate, PEEK, and Ultem are common choices. Each material has different strengths. Some resist heat well. Others are very tough. Tell us what you need the part to do. We help pick the best plastic.

How precise are the parts you make? We get very close to your drawing. CNC machining is extremely accurate. It can hit tight tolerances easily. 3D printed parts are also precise. The accuracy depends on the process used. We always aim for the specs you give us.

Should I use CNC or 3D printing? It depends on your project. CNC is best for very strong parts. It also works for complex shapes needing smooth finishes. 3D printing excels at complex, one-off designs. It’s faster for prototypes. Talk to us about your part. We suggest the right method.

How long will it take? Turnaround varies. Simple 3D prints might be ready in days. Complex CNC jobs take longer. We consider part size, design complexity, and material. We give a clear timeframe after reviewing your files. Rush services are possible for urgent needs.

What file format should I send? Send CAD files like STEP or IGES. These formats work best. STL files are good for 3D printing. We can handle other common formats too. Just ask if you’re unsure. Clear drawings help us quote faster.

(CNC Machining 3D Printing Service Engineering Plastic 3D Printing CNC )