Discover a professional 3D printing powder supplier

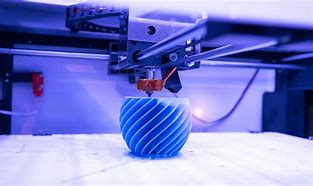

Title: Metal Bed Magic: Should You Print Directly on Your 3D Printer’s Hot Plate?

(should you print on the metal bed of a 3d printer)

You got your shiny new 3D printer. It has a metal bed. Looks tough. Feels cold. You wonder, can I just slap my plastic right onto that metal? Good question. Let’s dig in.

1. What is a Metal Bed?

The metal bed is the flat plate on your 3D printer where the magic starts. Your printer builds the object layer by layer right on top of this plate. It’s usually made from aluminum. Aluminum is a good metal for this job. It heats up evenly. It cools down fast too. This metal plate sits under the glass or other build surfaces you might use. Sometimes, it is the surface you print on directly. Think of it as the foundation. A strong foundation means your print sticks well. A bad foundation means warping, lifting, and failed prints. The metal bed is key.

2. Why Print Directly on Metal?

Printing directly on the metal bed has some big pluses. First, it gives a super smooth bottom layer on your print. If you like that sleek, shiny finish, metal can deliver. Second, it heats up fast and spreads that heat evenly. This is great for making the first layer stick properly. Good adhesion is everything in 3D printing. Third, it’s tough. Metal doesn’t scratch easily. It lasts a long time. You don’t need to replace it like some other surfaces. Fourth, it cools down quickly when the print is done. This can help the print pop off easier sometimes. Also, it’s simple. No extra sheets or tapes to buy and mess with. Just clean metal and go. For many materials, especially PLA, this can work really well.

3. How to Print Successfully on Metal

Okay, you want to try printing straight on the metal. You need to do it right. Here’s how. First, keep it clean. Really clean. Fingerprints are the enemy. They leave oil. Oil makes plastic not stick. Wipe the bed down with isopropyl alcohol (like rubbing alcohol) before every print. Use a lint-free cloth. Second, level your bed perfectly. This is always important, but even more so on bare metal. The nozzle must be the exact right height above the bed. Too high, and the plastic doesn’t squish down. Too low, and it scrapes. Third, get the temperature right. For PLA, try heating the bed to around 60 degrees Celsius. This helps the first layer grip. Fourth, consider a little sticky stuff. Even on bare metal, a light spray of hairspray or a super thin layer of glue stick can help. It creates a sticky surface for the plastic to grab onto. Finally, let the bed cool completely after printing. Metal contracts as it cools. This often makes the print release on its own. If it doesn’t, use a putty knife gently. Don’t force it.

4. Applications: When Metal Beds Shine

Metal beds are awesome for certain jobs. They are perfect for large, flat prints. Think big panels or bases. The even heat helps prevent warping on these big surfaces. They are also great for prototypes needing a smooth bottom finish. If you’re printing functional parts where the bottom surface needs to be flat and strong, metal is good. It’s also handy for quick prints. You don’t need to prep another surface. Just wipe and print. Hobbyists love this simplicity. Professionals use it for repeat jobs where consistency matters. The metal bed heats up like a champ every time. It gives reliable results print after print. If you print mostly PLA or PETG, the metal bed can be your go-to surface. It’s straightforward and effective.

5. FAQs About Metal Bed Printing

People ask a lot about printing on metal. Here are the common ones.

Will scraping damage the metal bed? Maybe. If you use a metal scraper too hard, you can scratch it. Use a plastic scraper or putty knife first. Be gentle. Let cooling do the work if you can.

Do I always need glue or hairspray? Not always. For PLA, a clean, hot bed often sticks fine. But a little glue stick or hairspray makes it much more reliable. It acts like insurance against lifting. For ABS or PETG, you usually need some adhesive help.

What about other materials like TPU? Flexible filaments like TPU can stick too well to bare metal. It might be hard to remove. It’s safer to use something like blue painter’s tape or a PEI sheet on top of the metal for these materials.

My print still won’t stick! Check your bed level again. Make sure it’s spotlessly clean. Try increasing the bed temperature a bit. Slow down the first layer print speed. Make sure the nozzle is close enough. Try a thin layer of glue stick.

(should you print on the metal bed of a 3d printer)

Is the metal bed hotter than other surfaces? Not necessarily. The temperature you set is what matters. Aluminum spreads heat quickly, so the surface temperature should match your setting well. It might heat up faster than a thick glass bed though.