Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

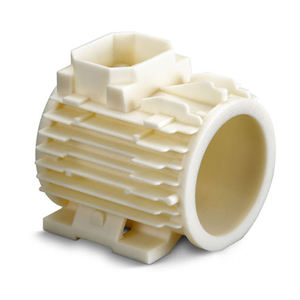

Overview of Action Figure Model Design SLA SLS 3D Printing Service for Plastic Rapid Prototype

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of Action Figure Model Design SLA SLS 3D Printing Service for Plastic Rapid Prototype

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(Action Figure Model Design SLA SLS 3D Printing Service for Plastic Rapid Prototype)

Specification of Action Figure Model Design SLA SLS 3D Printing Service for Plastic Rapid Prototype

Need action figures fast? Our SLA and SLS 3D printing services deliver plastic models swiftly. Obtain thorough designs for your plaything styles without waiting weeks. We specialize in bringing your figure ideas to life.

SLA printing makes use of a laser to cure liquid resin layer by layer. This approach attains extremely smooth surfaces and sharp information. It’s excellent for recording great functions like facial expressions, appearances on outfits, or little accessories. The final parts look fantastic right off the printer. You get high-resolution designs suitable for painting and display.

SLS printing uses a laser to fuse powdered nylon fragments. This constructs solid, sturdy plastic parts. SLS components can hold up against handling and testing. They are much less weak than run-down neighborhood components. This makes SLS suitable for practical models or parts requiring some adaptability. Assume joints, movable limbs, or components that snap with each other.

Both methods use special advantages for action number advancement. Run-down neighborhood gives you the most effective aesthetic information for preliminary look. SLS provides tougher parts for checking how things move or fit. We assist you select the right modern technology. It relies on your number’s certain requirements and phase of growth.

We deal with numerous plastic products. Each deals different properties like stamina, flexibility, or color. Review your task goals with us. We suggest the very best material and process. We manage files from usual 3D layout software application. Simply send us your model.

Turnaround times are typically simply a few days. Pricing depends upon the model dimension, product picked, and printing time required. Get a fast quote by sending your style files. Our group prepares to assist with your fast prototyping needs. Start creating your next activity figure today.

(Action Figure Model Design SLA SLS 3D Printing Service for Plastic Rapid Prototype)

Applications of Action Figure Model Design SLA SLS 3D Printing Service for Plastic Rapid Prototype

Activity number creators need fast, accurate prototypes. Our SLA and SLS 3D printing services deliver precisely that. Forget waiting weeks for typical approaches. Get your concepts right into concrete type promptly. This speed lets you test styles quick. You can see how parts mesh. You can check the general look beforehand. Making modifications is simple before dedicating to expensive manufacturing tooling.

Run-down neighborhood printing succeeds at catching fine details. It generates exceptionally smooth surface areas. This is vital for action numbers. Think about faces, detailed shield structures, or little accessories. SLA makes these features sharp and clean. The surface area coating is ready for painting. You obtain a reasonable appearance right off the printer. This aids you judge the end product’s appearance accurately.

SLS printing utilizes nylon powder. It develops solid, sturdy components. These parts can deal with tension. You can check relocating joints. You can inspect articulation points like joints and knees. SLS prototypes are tough sufficient for practical screening. They let you guarantee components relocate smoothly without damaging. You avoid surprises later in manufacturing.

We provide various products for different demands. Pick common materials for detailed looks. Use engineering-grade materials for more powerful parts needing screening. The option relies on your goal. Our professionals help you pick the ideal technology. Get your models fast. Fine-tune your activity number styles effectively. Relocate from principle to final model with self-confidence.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Action Figure Model Design SLA SLS 3D Printing Service for Plastic Rapid Prototype

Here are the top five questions people ask about our action figure model design and 3D printing service using SLA and SLS.

What is the difference between SLA and SLS printing for my action figure? SLA uses a laser to harden liquid resin layer by layer. This gives very fine details and a smooth surface. SLS uses a laser to fuse tiny powder particles together. It creates strong parts but the surface is rougher. Choose SLA for amazing detail. Pick SLS for durability.

How smooth will the surface of my printed action figure be? If you use SLA printing, the surface comes out very smooth right off the printer. SLS parts will feel a bit sandy. You can always sand and paint both types after printing. This makes them look perfect.

What materials can I use for my action figure prototype? For SLA printing, we offer tough resins. These resins mimic the feel of plastic toys. SLS printing uses nylon powder. This nylon is strong and flexible. Both materials are good for checking your design.

Are there size limits for printing an action figure? Yes, printers have maximum build sizes. We have machines that can handle figures up to 30 centimeters tall. If your figure is bigger, we can print it in separate pieces. Then we assemble the pieces for you.

How much does it cost and how long will it take? The cost depends on the figure’s size, the material you choose, and the printing method. Small, simple figures cost less. Big, complex figures cost more. SLA printing is usually faster than SLS. Most orders are ready within a few days. We give quotes quickly.

(Action Figure Model Design SLA SLS 3D Printing Service for Plastic Rapid Prototype)