Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

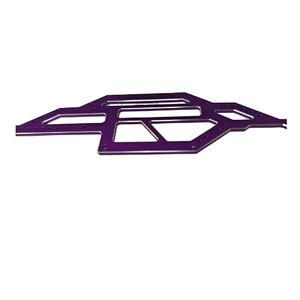

Overview of Customized Titanium Alloy Stainless Steel cnc parts 3d printing machine plastic metal 3d print

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

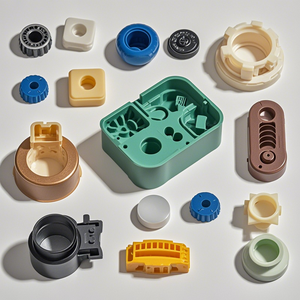

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of Customized Titanium Alloy Stainless Steel cnc parts 3d printing machine plastic metal 3d print

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(Customized Titanium Alloy Stainless Steel cnc parts 3d printing machine plastic metal 3d print)

Specification of Customized Titanium Alloy Stainless Steel cnc parts 3d printing machine plastic metal 3d print

We build personalized parts specifically just how you need them. Our equipments manage difficult products like titanium alloy and stainless-steel. We use CNC machining and 3D printing with each other. This gives you strong, precise parts. Fail to remember off-the-shelf options. Your layout gets made just right.

Choose titanium for its incredible toughness and lightweight. It’s ideal for demanding jobs. Stainless-steel supplies fantastic rust resistance. It’s likewise extremely long lasting. We work with numerous plastics too. This implies we can make nearly any kind of part you picture.

Our procedure integrates advanced methods. We start with 3D printing for complex shapes. This additive approach constructs layer by layer. Then, CNC machining takes control of. This subtractive approach cuts and completes the part. The result is an excellent surface area and limited resistances. You obtain the advantages of both modern technologies.

This is ideal for prototypes and end products. Conserve time getting your concepts into physical type. Required low-volume production? We can take care of that too. Our abilities fit many industries. Aerospace, vehicle, clinical, and durable goods all benefit. We help transform your ideas into truth rapidly. Obtain useful components faster than traditional techniques permit.

(Customized Titanium Alloy Stainless Steel cnc parts 3d printing machine plastic metal 3d print)

Applications of Customized Titanium Alloy Stainless Steel cnc parts 3d printing machine plastic metal 3d print

Customized titanium alloy and stainless steel CNC components made with 3D printing machines provide powerful options. These parts combine innovative manufacturing methods. CNC machining offers specific ending up. Steel 3D printing develops complex forms layer by layer. Plastic 3D printing also contributes in prototyping and tooling. This mix creates solid, custom-made parts quickly.

Aerospace applications profit significantly. Titanium alloys are light yet extremely solid. This is important for aircraft structures. Engine components withstand high warm. Customized brackets and installations conserve weight. Decreasing weight improves fuel performance. Stainless-steel parts handle harsh environments. Landing gear components need this sturdiness.

The medical area uses these components extensively. Surgical devices need precision. Implants like hip joints must be biocompatible. Titanium alloys integrate well with bone. Personalized implants fit clients perfectly. 3D printing permits unique patient-specific layouts. Medical tool prototypes are created much faster.

Automotive makers value these parts. High-performance automobiles require resilient engine parts. Custom titanium exhaust systems resist heat. Lightweight parts enhance speed. Prototyping new auto styles is effective. Both plastic and steel printing aid below. Tooling for production lines is also created.

Industrial machinery relies on hard parts. Customized gears and bearings last longer. Stainless-steel stands up to wear in rough problems. Oil and gas equipment encounters severe pressure. Mining machinery requires robust parts. 3D printing enables quick replacement part production. Downtime is lessened.

Consumer items utilize this modern technology also. High-end watches include intricate metal components. Bike structures are lighter and stronger. Sporting products like golf clubs execute better. Custom-made layouts meet specific athlete needs. The opportunities are increasing continuously.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Customized Titanium Alloy Stainless Steel cnc parts 3d printing machine plastic metal 3d print

Here are 5 common questions about our custom titanium alloy, stainless steel CNC parts, and plastic/metal 3D printing services:

What materials can you work with? We handle titanium alloys like Ti-6Al-4V and various stainless steel grades. We also offer plastic 3D printing materials including ABS, nylon, and polycarbonate. Metal 3D printing uses specific powders. Tell us your material needs.

How customized can the parts be? We make parts exactly to your specifications. Send us your CAD files or sketches. We can machine complex shapes from metal blocks. We can 3D print intricate plastic or metal designs impossible with traditional methods. We adapt to your project.

How precise is the work? We achieve high precision. CNC machining delivers tight tolerances and fine surface finishes. 3D printing accuracy depends on the technology and material. We choose the best method for your precision requirements. We ensure parts meet your standards.

How long does it take? Lead times vary. Simple CNC jobs might finish fast. Complex 3D prints or large batches take longer. We provide estimated timelines after reviewing your design and quantity. We keep you updated on progress. Rush services are available.

What affects the cost? Several factors influence price. Material choice matters. Titanium costs more than some plastics. Part complexity impacts machining time. Size affects material use. Quantity changes unit cost. We give transparent quotes based on your specific job details.

(Customized Titanium Alloy Stainless Steel cnc parts 3d printing machine plastic metal 3d print)