Discover a professional 3D printing powder supplier

Metal 3D printing is making big waves. It’s no more simply a trendy idea for the future. It’s right here. And it’s changing exactly how points get made. This tech constructs complex metal parts layer by layer. It makes use of digital layouts. So, what sectors are jumping on this bandwagon? Allow’s dive in.

(what industries use metal 3d printing)

1. What is Steel 3D Printing? .

Consider regular printing, but as opposed to ink on paper, it’s steel powder or cord. Metal 3D printing, or additive manufacturing, creates strong items from electronic data. It builds them up, one tiny layer each time. This is different from removing product like conventional machining.

Several techniques exist. Some thaw steel powder with lasers or electron beam of lights. Others bind powder together with a glue-like representative. Later on, warmth merges it. Some also spray molten steel. The typical string? Building parts straight from digital layouts. This opens doors to forms difficult to make otherwise. Think interior networks, intricate latticeworks, or complex geometries. It uses style freedom typical approaches can’t match.

2. Why Pick Metal 3D Printing? .

Why are companies changing? The benefits are solid. Initially, style liberty is massive. Designers aren’t restricted by old tooling restraints. They can make components lighter, stronger, or a lot more efficient. They can incorporate lots of pieces into one solitary part. This lowers assembly time and potential failure factors.

Second, it allows for modification. Making one distinct component is commonly as very easy as making a thousand identical ones. This is perfect for clinical implants or specialized aerospace elements. Each item can be tailored specifically to its task.

Third, speed issues. Developing models is much faster. Style changes take place quickly. Obtaining components for testing or production takes much less time. For low-volume production, it can be much quicker than setting up traditional production lines.

Fourth, it can minimize waste. Standard approaches frequently remove as much as 90% of the product. Steel 3D printing generally utilizes only the material required for the part itself. That conserves cash and is better for the atmosphere.

Finally, it allows development. Parts can be developed specifically for additive production. This unlocks brand-new opportunities in efficiency and feature.

3. How Does Metal 3D Printing Work? .

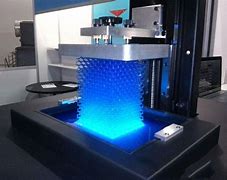

The procedure differs by technology. Allow’s take a look at 2 typical types. Powder Bed Combination is prominent. Right here, a slim layer of fine metal powder spreads throughout a build platform. A powerful laser or electron beam of light after that precisely melts the powder. It follows the cross-section of the part for that layer. As soon as one layer is done, the platform decreases. Another powder layer spreads on top. The procedure repeats, melting the brand-new layer and merging it to the one listed below. This proceeds up until the entire component is constructed inside a powder bed. After cooling, the excess powder is removed.

Directed Power Deposition functions in a different way. Below, metal powder or cable is fed into a nozzle. A laser, electron beam, or plasma arc melts the product right at the factor of deposition. The nozzle actions, depositing molten metal specifically where required, layer by layer. This technique is wonderful for including attributes to existing parts or repairing components. It’s likewise used for larger frameworks.

Binder Jetting includes spreading out metal powder. A fluid binding agent is after that printed onto the powder bed, gluing particles together in the shape of the component. This creates a ‘environment-friendly’ component. Later, this component is sintered. High warmth fuses the steel fragments into a strong item. Often, molten steel is infiltrated to boost density.

After printing, parts typically require finishing. Support structures could be removed. Parts might be machined for accuracy surface areas. Warm treatment prevails to eliminate stress and enhance toughness. The precise steps rely on the printing method and the part’s demands.

4. Industries Utilizing Steel 3D Printing .

So, that’s in fact utilizing this? Many markets are taking on steel 3D printing.

Aerospace and defense lead the cost. Weight is vital here. Every extra pound saved suggests fuel savings. Steel 3D printing makes exceptionally lightweight yet strong parts. Think turbine blades with inner air conditioning networks. Think complicated fuel nozzles made as one piece as opposed to twenty. Think lighter braces and housings. Business make flight-ready elements and prototypes faster. Custom-made parts for satellites or rockets are likewise common. Fixing high-value aerospace components is an additional expanding use.

Medical and dental applications are booming. Personalization is essential. Surgeons obtain patient-specific implants. Knee replacements or spine fusion cages fit perfectly. Dental laboratories develop crowns, bridges, and orthodontic gadgets rapidly. Surgical devices can be made with one-of-a-kind attributes for details procedures. Biocompatible steels like titanium are extensively used. The ability to produce permeable frameworks assists bone become implants. This enhances healing.

Automotive and motorsports accept it also. High-performance cars and trucks need strong, light-weight components. Metal 3D printing provides. Customized engine elements, lightweight braces, intricate warm exchangers, and also whole turbocharger settings up are being published. Solution One teams press boundaries. They rapidly model and produce parts difficult to machine. Tooling for manufacturing cars, like jigs and components, is also made faster and less costly with 3D printing.

Power sector applications are growing. Oil and gas business use it for hard components in severe atmospheres. Custom-made drill head parts. Facility shutoffs. Heat exchangers for power generation. Generator elements for both standard and renewable energy. The geothermal industry uses corrosion-resistant parts. Nuclear applications require specific parts. The capability to make components on-demand decreases downtime. It aids in remote places.

Industrial equipment and tooling advantage considerably. Factories utilize steel 3D printing for customized jigs and fixtures. These hold parts throughout setting up. They are made faster and frequently much better than typical techniques. End-of-arm tooling for robotics is personalized. Mold and mildews and craves plastic injection or steel casting incorporate intricate air conditioning channels. This boosts production speed and part high quality. Making spare components on-demand conserves money and time. It prevents long waits for substitutes.

5. Metal 3D Printing Frequently Asked Questions .

People usually have questions. Right here are some usual ones.

Is it solid? Yes. Correctly published and processed steel parts can be as solid, in some cases more powerful, than typically made parts. The product homes meet sector standards. Examining guarantees this.

Just how much does it cost? It depends. The machines and materials are expensive. However, for intricate components, reduced volumes, or custom products, it can be economical. It prevents expensive tooling. It decreases material waste. It reduces lead times. The value originates from style liberty and rate, not simply per-part cost.

What metals can be published? Many. Usual ones include titanium and its alloys. Stainless-steels. Device steels. Nickel-based superalloys. Cobalt-chromium. Light weight aluminum alloys. Copper. Even precious metals like gold and silver. New products are constantly being developed.

Is the surface smooth? Not constantly right off the printer. Components typically have a somewhat harsh surface. Post-processing like machining or polishing prevails for vital surface areas. Some modern technologies generate smoother surface areas than others. It depends upon the application’s demands.

Is it replacing traditional manufacturing? Not completely. It’s one more device. It masters specific areas. Complicated designs. Custom-made parts. Low-volume manufacturing. Quick prototyping. Repair. For high-volume, easy parts, traditional methods like spreading or machining are usually more affordable and quicker. Steel 3D printing matches them.

How accurate is it? Really exact. Modern makers accomplish high accuracy. Tolerances are tight. Factors like part size, geometry, and post-processing influence the last accuracy. It satisfies the demanding requirements of aerospace and clinical areas.

(what industries use metal 3d printing)

Can it make large parts? Yes, yet dimension is restricted by the maker’s develop quantity. Some printers can make components over a meter in dimension. For large frameworks, routed power deposition is commonly used. Multiple parts can also be printed and set up.